Three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode and preparation method thereof

A carbon nanotube, three-dimensional network technology, applied in battery electrodes, metal material coating process, liquid chemical plating, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (1) Carry out impurity removal and dispersion treatment on CNTs, select carbon nanotubes with an outer diameter of 10~20nm and a length of 1~3μm,

[0071] The steps for treating CNTs are as follows: first add HCl solution with a mass concentration of 18.25% into the container containing CNTs to obtain a pretreatment solution with a CNTs content of 2 g / L;

[0072] Then ultrasonically vibrate the above-mentioned pre-treatment liquid while mechanically stirring for 2 hours, then magnetically stir for 10 hours, then separate the CNTs from the pre-treatment liquid, and finally dry the CNTs for 24 hours;

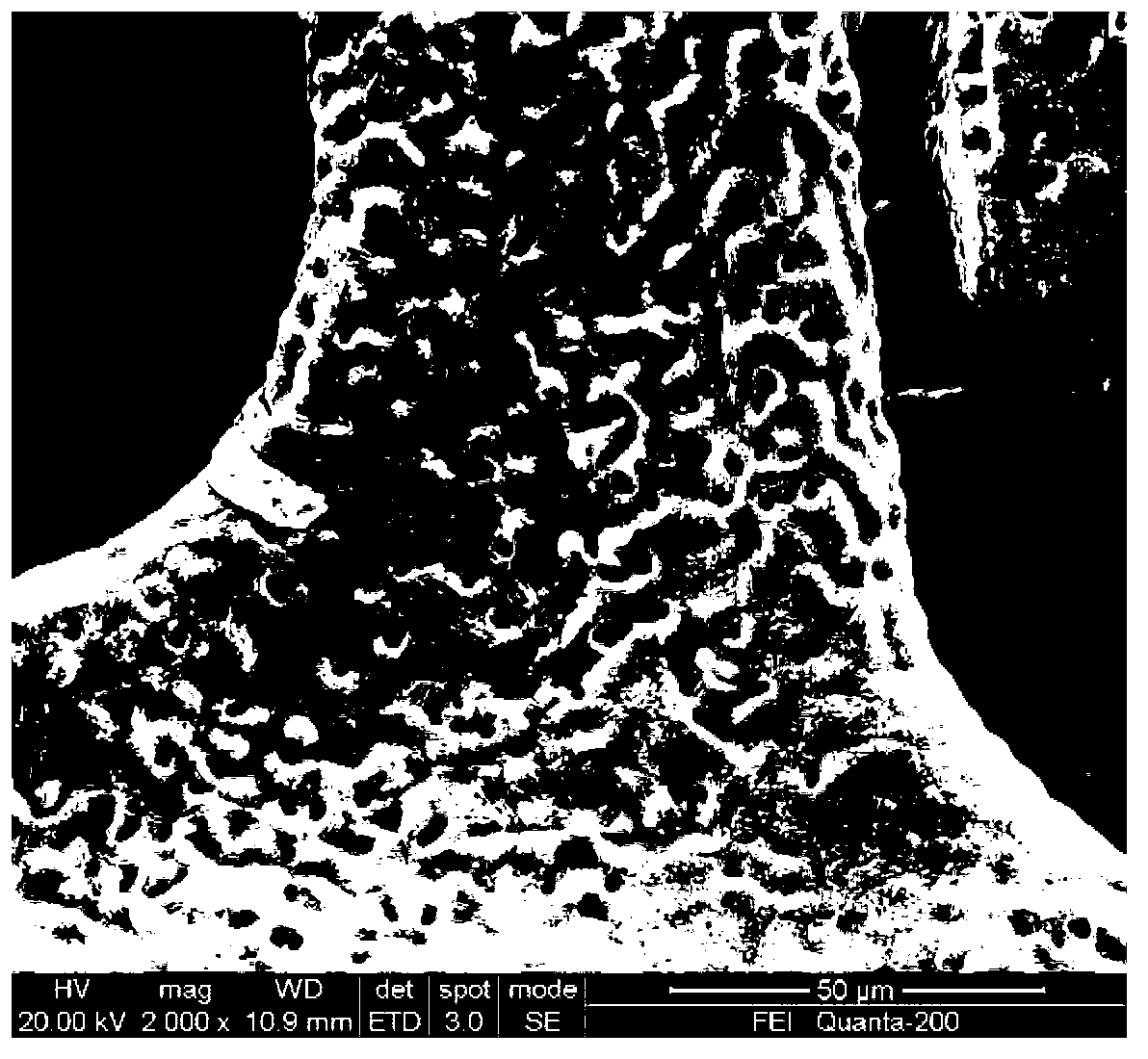

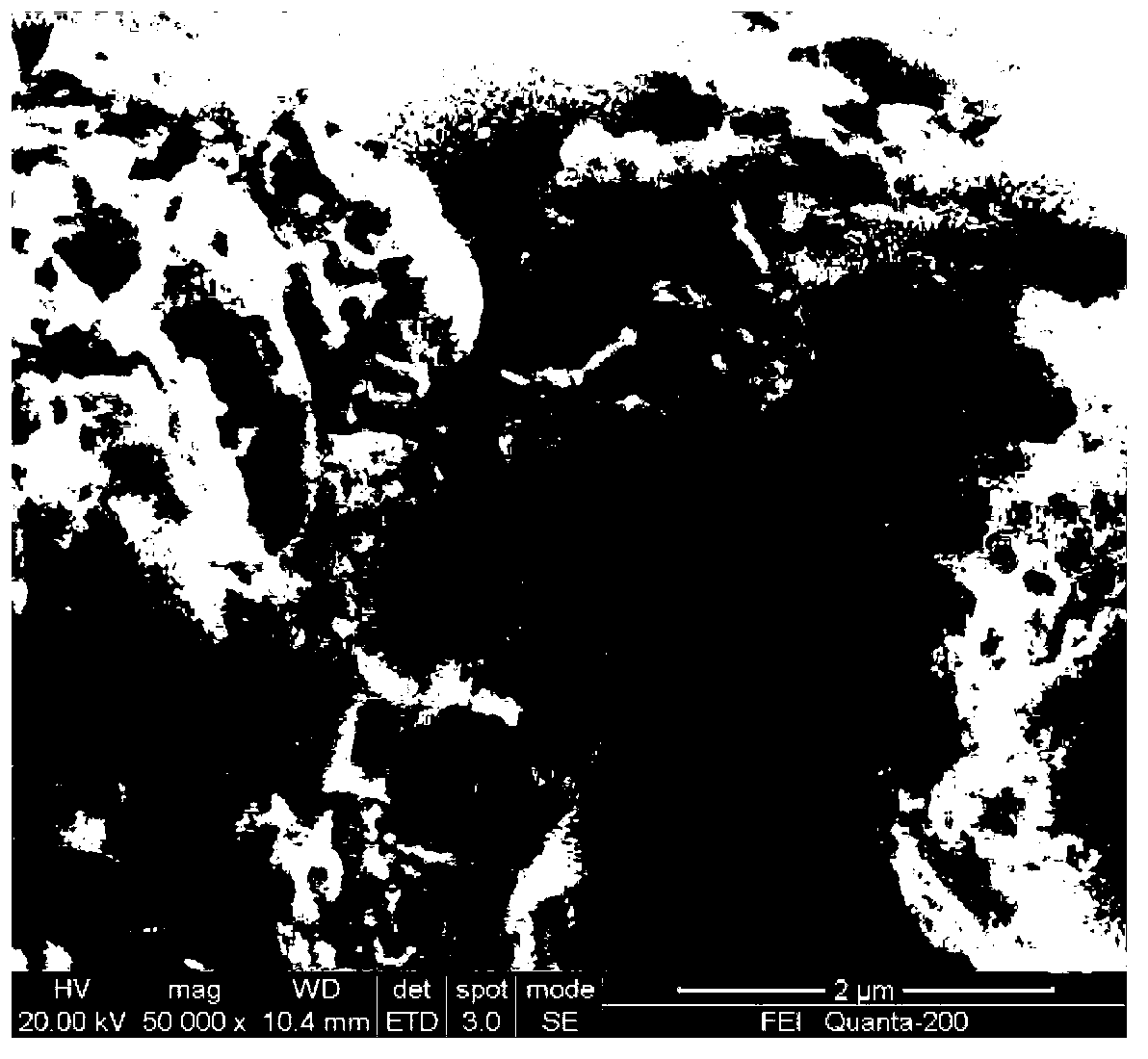

[0073] (2) then adopt electroless plating to the nickel coating that CNTs plating thickness is 100nm,

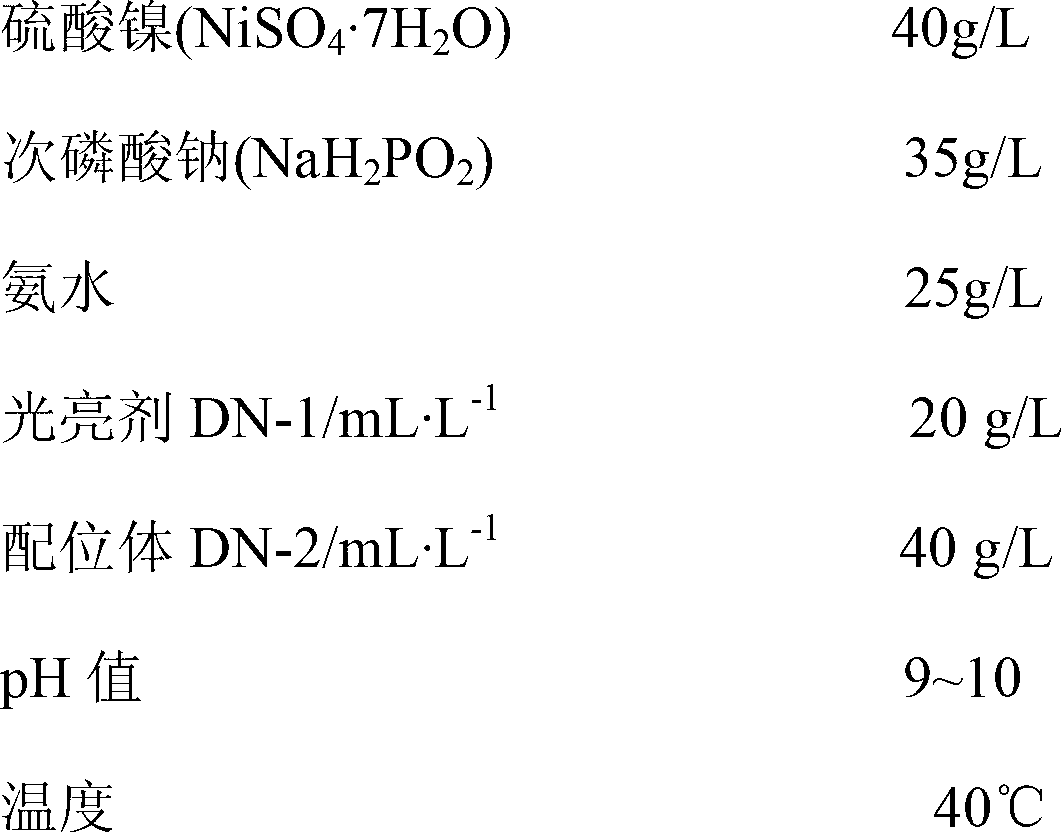

[0074] The formulation and conditions of electroless nickel plating are as follows:

[0075]

[0076] (3) Using the nickel-coated CNTs obtained in step (2), the Cu-(CNTs-Ni) composite coating with a thickness of 2 μm was plated on the copper foam with a specification ...

Embodiment 2

[0098] The rest of the steps are the same as in Example 1, using copper foam with a specification of 120PPI as the substrate, composite electroplating a Cu-(CNTs-Ni) composite coating with a thickness of 1 μm, and then composite electroplating a 2 μm Sn-(CNTs-Ni) alloy coating, and finally Heat treatment at 200°C for 10 hours to obtain a three-dimensional network tin-copper-nickel-CNTs alloy negative electrode. Using the conventional lithium-ion battery test method, the first discharge mass specific capacity of the negative electrode effective material is 587mAh / g. After 200 charging cycles, the specific capacity is still 563.5mAh / g. The specific capacity decays only 4%, and the Coulombic efficiency exceeds 96. %.

Embodiment 3

[0100] All the other steps are the same as in Example 1. Using copper foam with a specification of 120PPI as the substrate, composite electroplating with a Cu-(CNTs-Ni) composite coating with a thickness of 3 μm, and then electroplating a 2 μm Sn-(CNTs-Ni) coating by co-deposition, and finally heat treatment at 200 ° C for 2 hours A three-dimensional mesh tin-copper-nickel-CNTs alloy negative electrode is obtained. Using the conventional lithium-ion battery test method, the first discharge mass specific capacity of the negative electrode effective material is 607mAh / g. After 100 charging cycles, the specific capacity is still 588.8mAh / g. The specific capacity decays only 3%, and the Coulombic efficiency exceeds 97. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com