Preparation for polymer and method for chemically modifying carbon nano-tube

A technology of carbon nanotubes and polymers, applied in the field of materials, can solve the problems that the advantages cannot be fully exerted, and the composite materials are not ideally aggregated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

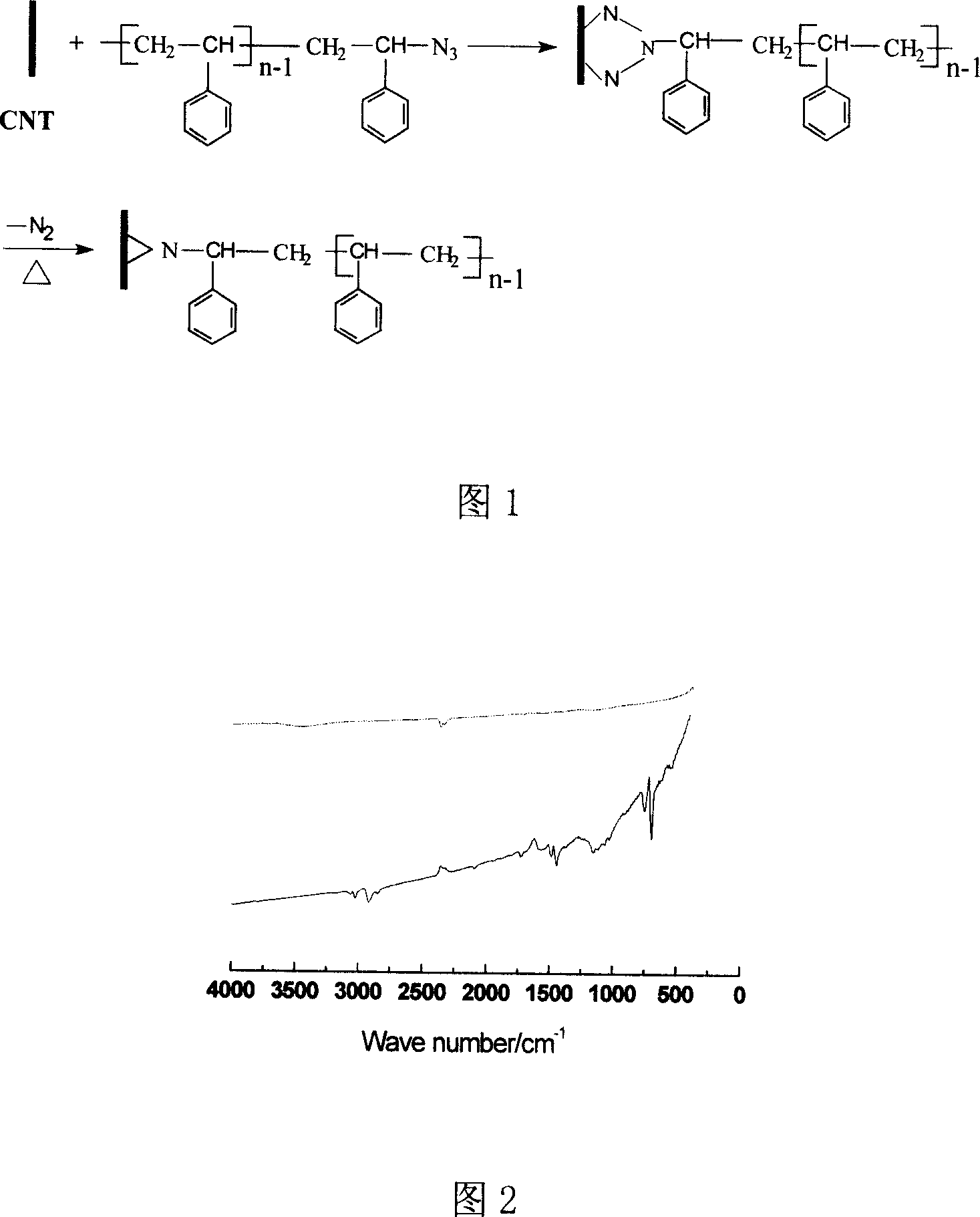

[0025] Single-walled carbon nanotubes prepared by polystyrene-modified chemical vapor deposition

[0026] (a) Preparation of PSt-Br

[0027] Put CuBr / Bipy in the reaction flask with a molar ratio of 1:3, seal it, vacuumize it, fill it with nitrogen, and repeat the operation 3 times to ensure that the ATRP reaction is carried out in an oxygen-free environment. Inject styrene monomer and an appropriate amount of dimethyl sulfoxide with a syringe, and stir at room temperature for 1 hour. Then the temperature was raised to 110° C., and ethyl α-bromopropionate (EBP) (CuBr:EBP:Bipy=1 mol:1 mol:3 mol) was injected. After reacting for 4 hours, tetrahydrofuran was added into the reaction flask, and after fully dissolving, it was precipitated in methanol. After filtration, the filter cake was re-dissolved in tetrahydrofuran and precipitated in methanol. After repeating the operation 3 times, it was filtered and vacuum-dried to obtain a white powder.

[0028] (b)PSt-N 3 preparation ...

Embodiment 2

[0033] Double-walled carbon nanotubes prepared by polystyrene-modified chemical vapor deposition

[0034] (a) Preparation of PSt-Br

[0035] Put CuBr / Bipy in the reaction flask with a molar ratio of 1:3, seal it, vacuumize it, fill it with nitrogen, and repeat the operation 3 times to ensure that the ATRP reaction is carried out in an oxygen-free environment. Inject styrene monomer and an appropriate amount of dimethyl sulfoxide with a syringe, and stir at room temperature for 1 hour. Then the temperature was raised to 110° C., and ethyl α-bromopropionate (EBP) (CuBr:EBP:Bipy=1 mol:1 mol:3 mol) was injected. After reacting for 4 hours, tetrahydrofuran was added into the reaction flask, and after fully dissolving, it was precipitated in methanol. After filtration, the filter cake was re-dissolved in tetrahydrofuran and precipitated in methanol. After repeating the operation 3 times, it was filtered and vacuum-dried to obtain a white powder.

[0036] (b)PSt-N 3 preparation ...

Embodiment 3

[0041] Single-walled carbon nanotubes prepared by poly(tert-butyl methacrylate) modified chemical vapor deposition

[0042] (a) Preparation of PtBmA-Br

[0043] Put CuBr / Bipy in the reaction flask with a molar ratio of 1:3, seal it, vacuumize it, fill it with nitrogen, and repeat the operation 3 times to ensure that the ATRP reaction is carried out in an oxygen-free environment. Inject tert-butyl methacrylate monomer and appropriate amount of dimethyl sulfoxide with a syringe, and stir at room temperature for one hour. Then the temperature was raised to 80° C., and ethyl α-bromopropionate (EBP) (CuBr:EBP:Bipy=1 mol:1 mol:3 mol) was injected. After reacting for 4 hours, tetrahydrofuran was added into the reaction flask, and after fully dissolving, it was precipitated in methanol. After filtration, the filter cake was re-dissolved in tetrahydrofuran and precipitated in methanol. After repeating the operation 3 times, it was filtered and vacuum-dried to obtain a white powder.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com