Construction method of vibrating dense macroporous pervious concrete pavement

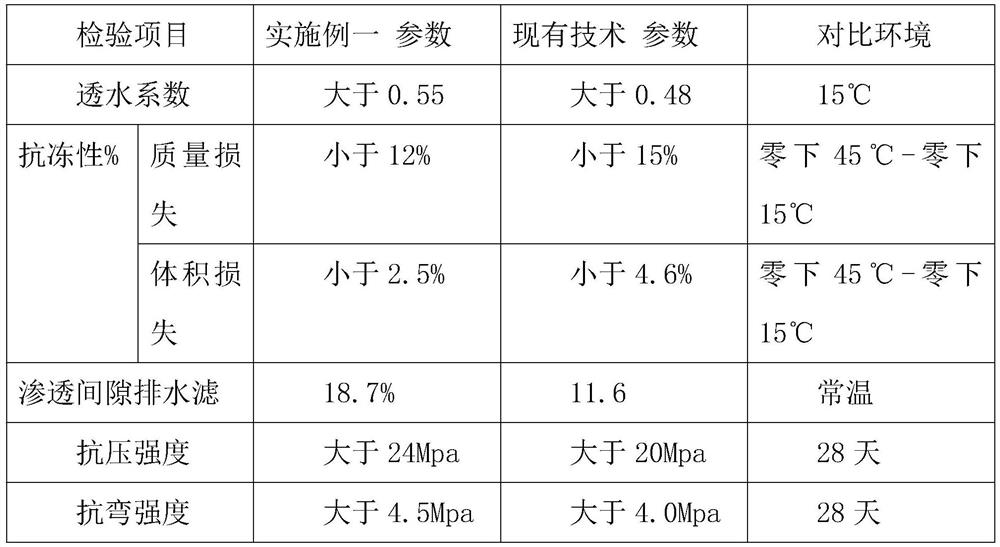

A technology of permeable concrete and large pores, which is applied to roads, roads, pavement details, etc., can solve the problems of poor water permeability, easy accumulation of water on roads, affecting public travel safety and traffic efficiency, and achieves less investment in equipment and faster construction speed. , the effect of process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

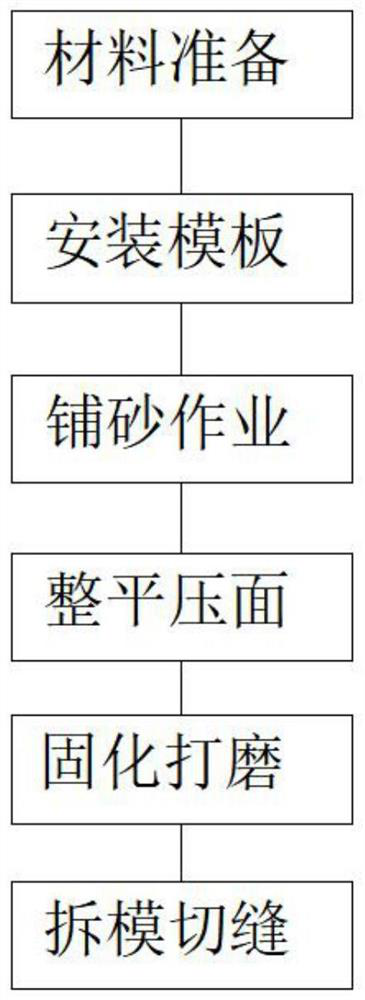

Embodiment 1

[0049]First, prepare for construction, prepare materials, make concrete equipment and pavement mold frames, and accurately measure the construction pavement; install the formwork on the construction pavement, the formwork surrounds the city in a strip and rectangular shape, while mixing to make concrete, pour the concrete raw materials to Inside the formwork, and pave the concrete; spread sand and gravel, spread evenly, and use the vibration motor on the outside of the formwork to manually spread the sand twice, using 2kg / m2, And use the slurry lifter to finish and calender; leveling, and at the same time, pressing the surface, after the concrete strength reaches 100%, the ground is polished, cured and brightened; the mold is removed, and the slit is processed, and then cleaned and maintained. The processing is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com