A Span Asymmetric Pit Gas Film Cooling Pass

A film cooling, asymmetric technology, applied in the direction of climate sustainability, blade support components, sustainable transportation, etc., can solve the problems of low cooling efficiency, difficult processing, easy blowing of cold air jets off the blade surface, etc., to achieve The effect of increasing the area, increasing the spanwise width, and increasing the spanwise coverage area of the gas film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

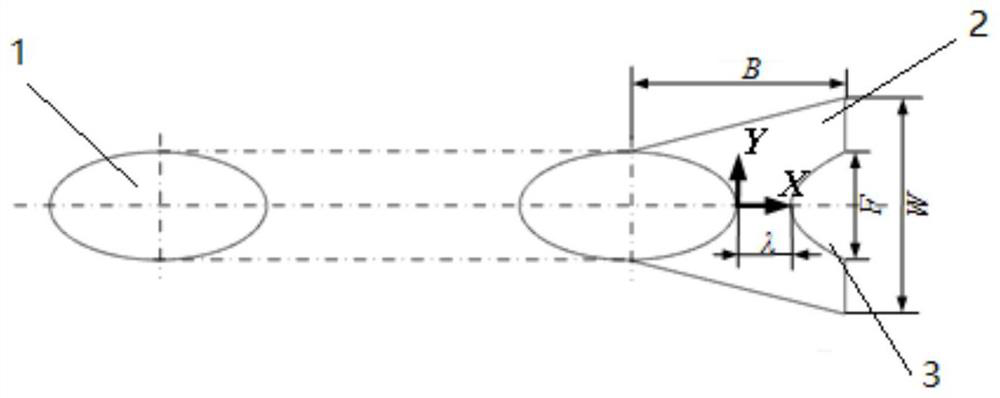

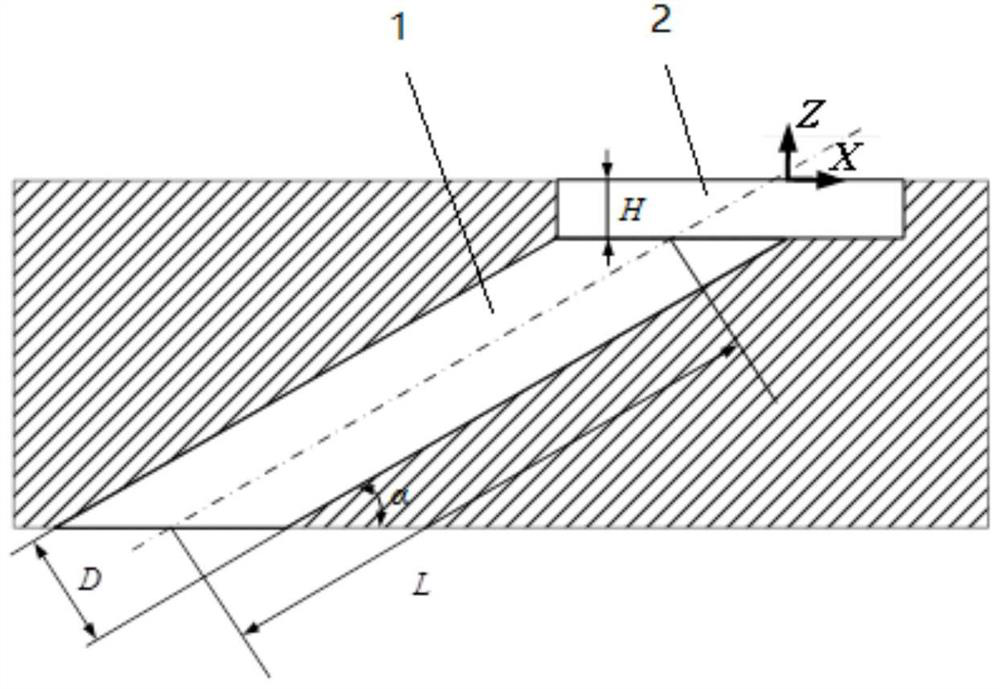

[0024] Embodiment 1: In the first embodiment of the present invention, there is provided a spanwise asymmetrical dimple gas film cooling hole structure that increases the spanwise expansion width of the downstream side of the vertical cross flow in the dimple expansion structure 2, Figure 2-1 , Figure 2-2 It is the geometrical structure diagram of the air-film cooling hole type of the spanwise asymmetric pit in Example 1 of the present invention. like Figure 2-1 As shown, the spanwise asymmetric pit structure is a pit expansion structure 2 that expands asymmetrically along the spanwise direction from both sides of the outlet of the cylindrical hole 1. W t Indicates that the spanwise expansion width of the upstream side of the internal cooling vertical cross flow is defined by W 0 express, W t / W 0 =1.25 is the main feature of this spanwise asymmetrical pit gas film cooling pass pattern Example 1 which is different from the original spanwise symmetrical pit gas film...

Embodiment 2

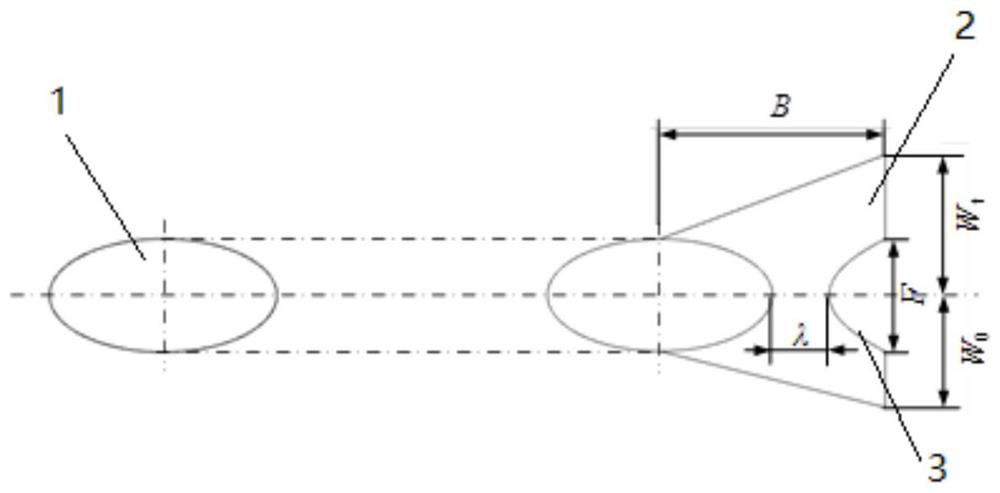

[0027] Embodiment 2: In the second embodiment of the present invention, a spanwise asymmetrical dimple gas film cooling hole structure is provided by offsetting the expansion-shaped boss at the downstream gas outlet of the dimple structure, Figure 3-1 , Figure 3-2 It is a structural diagram of Embodiment 2 of the present invention. The spanwise asymmetric pit structure has an arc-shaped expansion boss 3 on the gas outlet side of the pit, and the boss 3 is offset to the downstream side of the internal cooling vertical cross flow. The position of the expanded boss 3 presents an asymmetric distribution in the spanwise direction, which is the main feature of the second embodiment of the present invention that is different from the original spanwise symmetrical pit gas film cooling hole pattern. The front end of the boss 3 and the cylindrical hole 1 flow between the center line spanwise offset distance of K spanwise width with boss 3 F ratio K / F= 0.25.

[0028] In Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com