HEMT epitaxial structure with low buffer layer leakage current and HEMT device

A technology of epitaxial structure and leakage current, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of increasing the leakage current of the buffer layer, high leakage current of the buffer layer, and easy breakdown, so as to reduce leakage and improve breakdown Voltage, crack prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

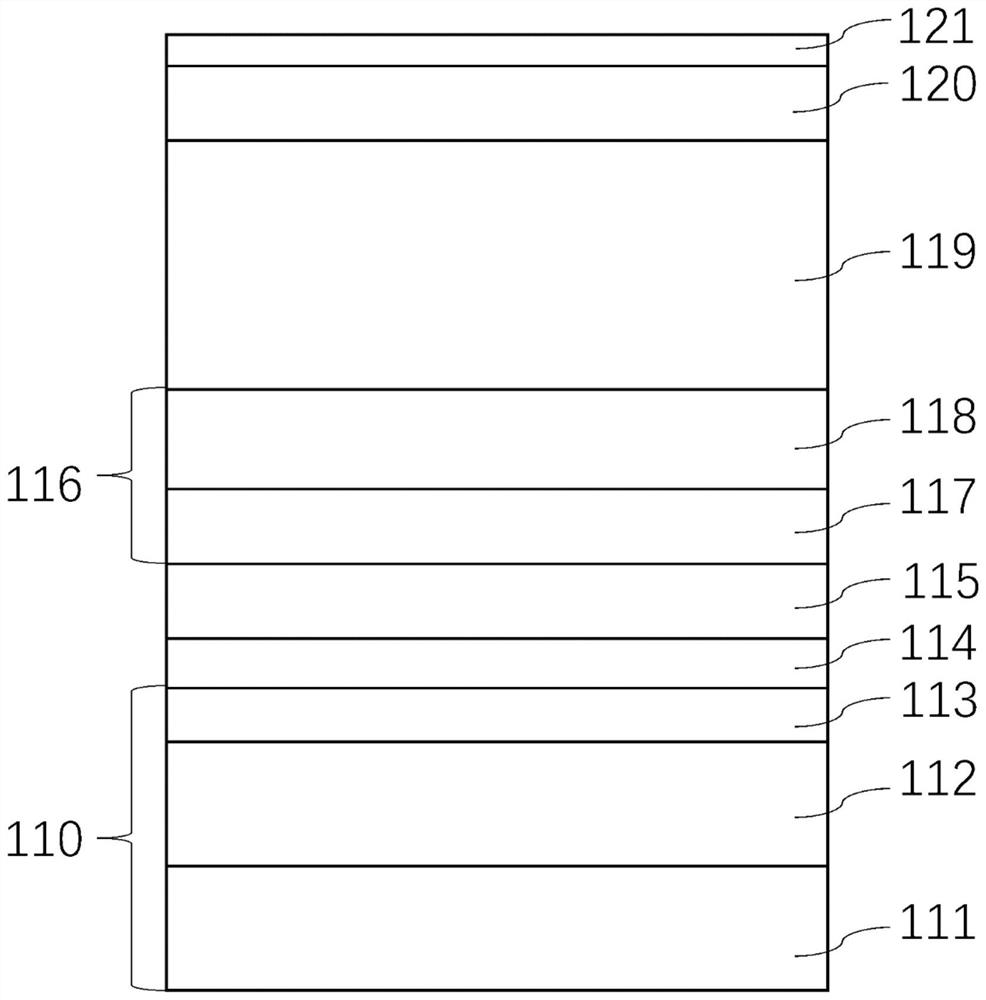

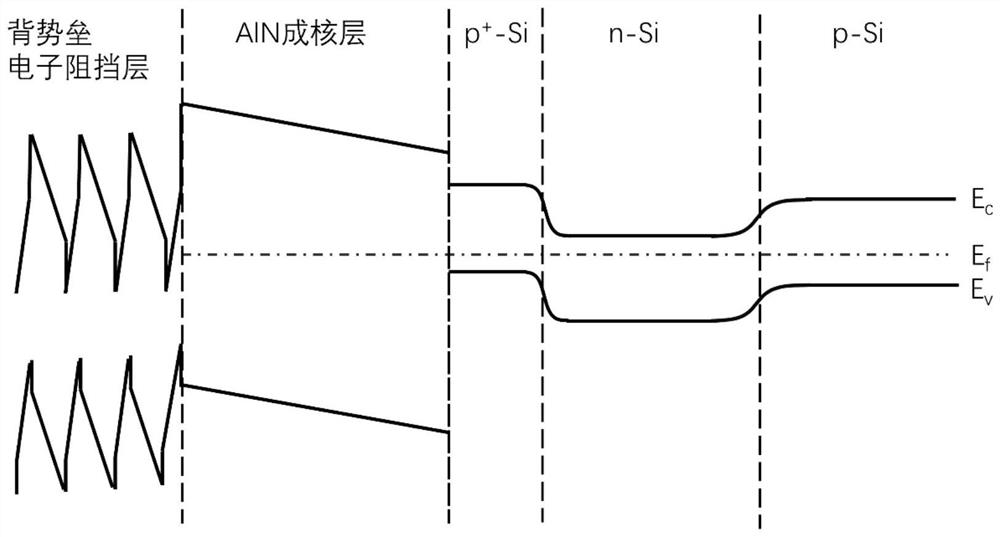

[0028] See figure 1 In the first aspect of the embodiment of the present invention, a HEMT epitaxial structure with low buffer layer leakage current is provided, including: a silicon substrate 110, an AlN nucleation layer 114, a back barrier electron blocking layer 115, a stress regulation and control layer arranged in order from bottom to top layer 116 , GaN high resistance layer 119 , GaN channel layer 120 and barrier layer 121 . The epitaxial structure can be grown by epitaxial growth techniques such as metal organic chemical vapor deposition (MOCVD) and molecular beam epitaxy (MBE).

[0029] The silicon substrate 110 includes: a first sub-substrate 111 , a second sub-substrate 112 and a third sub-substrate 113 arranged in sequence from bottom to top. Specifically, the AlN nucleation layer 114 is located on the third sub-substrate 113 .

[0030] The type of carriers (majority carriers) of the first sub-substrate 111 is opposite to the type of carriers (majority carriers) ...

Embodiment 2

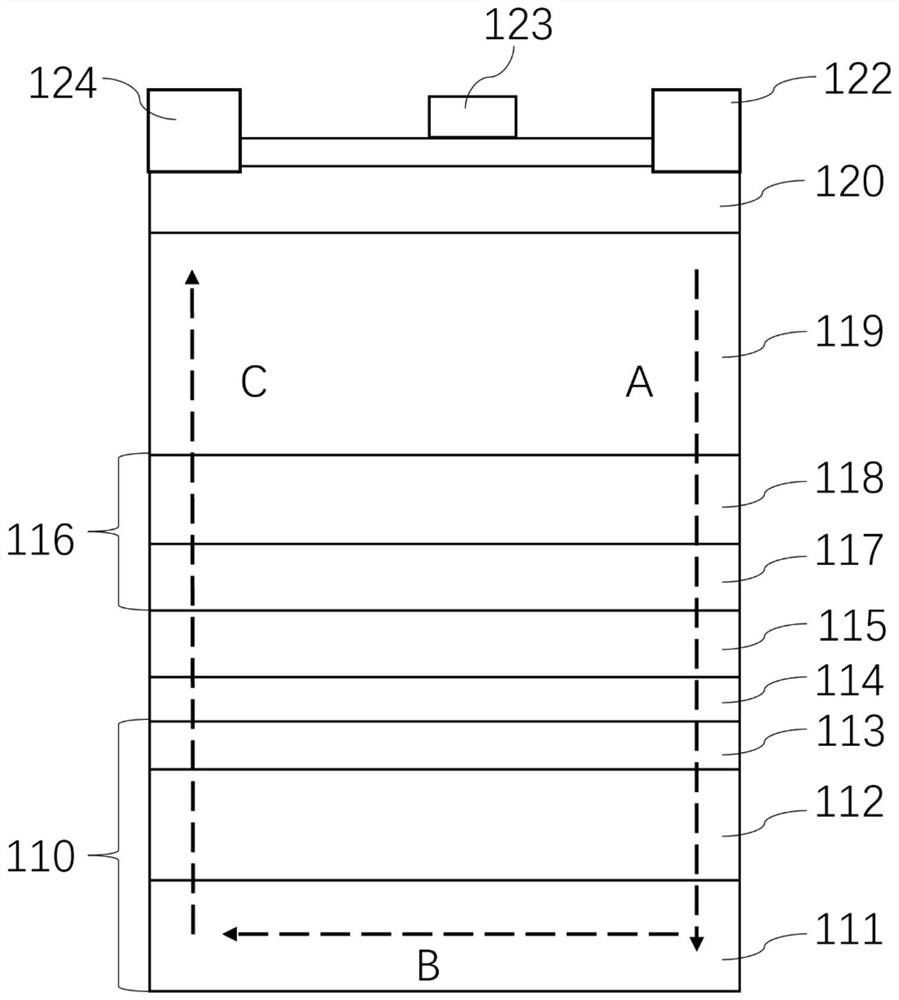

[0043] like figure 2 As shown, the second aspect of the embodiment of the present invention further provides a HEMT device with low buffer layer leakage current, including the source electrode 124 , the drain electrode 122 , the gate electrode 123 and the epitaxial structure in the first embodiment.

[0044] The source electrode 124 and the drain electrode 122 are located on the GaN channel layer 120 of the epitaxial structure and on both sides of the barrier layer 121 of the epitaxial structure, and the gate electrode 123 is located on the barrier layer 121 and between the source electrode 124 and the drain electrode 122 . Specifically, the drain electrode 122 and the source electrode 124 are deposited by electron beam evaporation process to form ohmic contact with two-dimensional electron gas of the channel layer, and the gate electrode 123 is deposited by electron beam evaporation process to form Schottky contact, and finally the HEMT device is prepared.

[0045] like f...

Embodiment 3

[0047] In one embodiment of the present invention, a HEMT epitaxial structure with low buffer layer leakage current includes: a silicon substrate 110 , an AlN nucleation layer 114 , a back barrier electron blocking layer 115 , and a stress control layer arranged in order from bottom to top layer 116 , GaN high resistance layer 119 , GaN channel layer 120 and barrier layer 121 . Among them, the epitaxial structure can complete the growth of each layer by metal organic chemical vapor deposition (MOCVD).

[0048] The silicon substrate 110 includes: a first sub-substrate 111 , a second sub-substrate 112 and a third sub-substrate 113 arranged in sequence from bottom to top. Specifically, the AlN nucleation layer 114 is located on the third sub-substrate 113 . P-type Si is selected as the first sub-substrate 111, and the first majority carrier concentration is 2.0×10 15 cm -3 , the part above the upper surface of the first sub-substrate 111 is doped with n-type by means of ion im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com