High-temperature-resistant carbon-fiber-core photoelectric composite overhead conductor

A technology of photoelectric composite and overhead wires, which is applied in the direction of light guides, fiber mechanical structures, and power cables including optical transmission components, etc., to achieve good heat conduction effects, improved tensile strength and temperature rise current carrying capacity, and guaranteed functional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments.

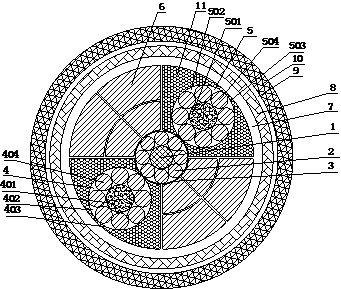

[0022] A high-temperature-resistant carbon fiber core photoelectric composite overhead wire includes a wire core, an optical fiber layer, a tightening tie 7, an insulating sheath-8, a heat-resistant layer 9 and an outer sheath 10 from the inside to the outside.

[0023] Among them, the wire cores are carbon fiber core 1, round aluminum wire 2 and insulating sheath 2 3 sequentially from inside to outside.

[0024] The carbon fiber core 1 is made of carbon fiber filaments as the central layer, and the outer layer is longitudinally wrapped with glass fiber filaments, impregnated with resin, and produced by a pultrusion process through a rod-making mold.

[0025] As a preferred embodiment of the present invention, the carbon fiber core 1 uses carbon fiber filament TR50S-12L as the central layer, and the outer layer is longitudinally wrapped with glass fiber roving EDR17-1200-38...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com