Dough kneading device for bread processing

A bread and noodle box technology, applied in the direction of application, dough mixer, horizontal installation tool mixing/kneading, etc., can solve the problems of flour sticking, poor molding effect, low efficiency of manual mixing, etc., and achieve high degree of automation, Effect of improving kneading quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

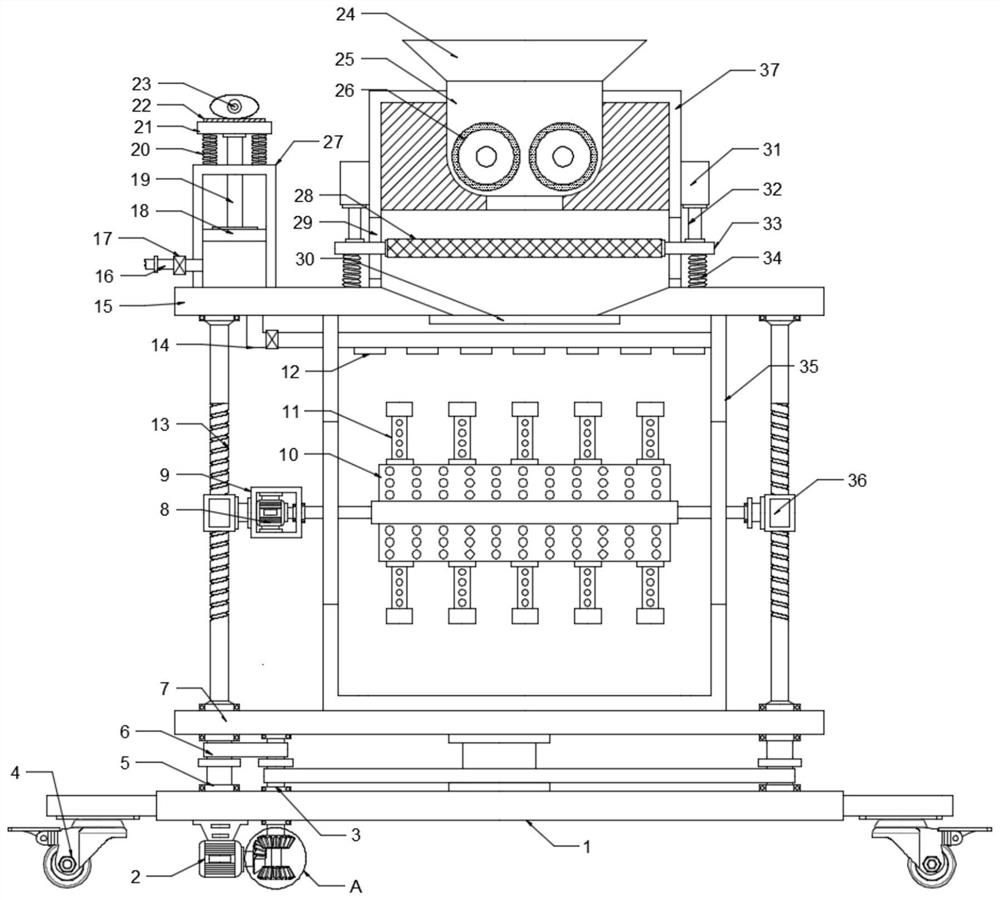

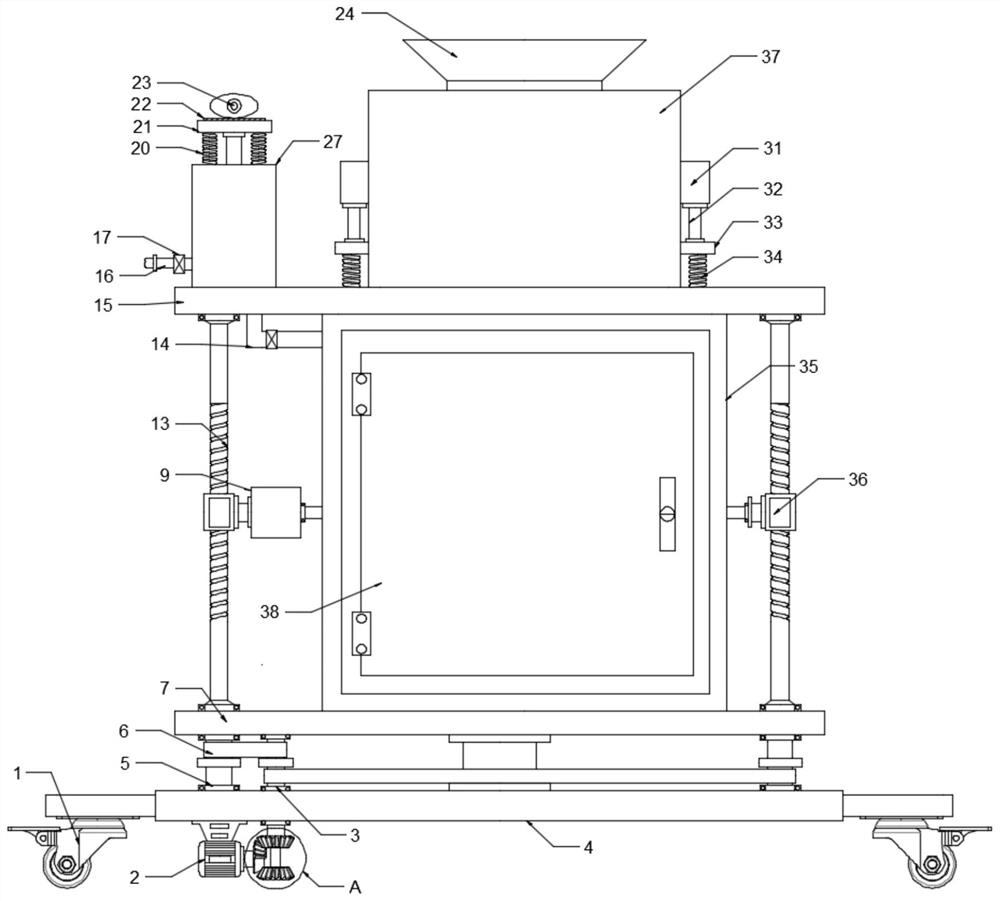

[0022] see Figure 1-4 , a kneading device for bread processing, comprising a support base 1 and a kneading box 35, the kneading box 35 is installed on the side of the support base 1, the upper surface of the support base 1 is fixedly connected to the bottom plate 7 through a connecting rod, the The kneading box 35 is fixedly connected to the bottom plate 7 by welding, and a support plate 15 is fixedly installed above the kneading box 35, and a grinding box 37 is arranged on the upper surface of the support plate 15, and a feed inlet 24 is set on the top wall of the grinding box 37 , the grinding tank 25 is set in the grinding box 37, and the grinding rollers 26 are arranged symmetrically on the left and right sides in the grinding tank 25. In the tank 25, the grinding rollers 26 on the left and right sides rotate inward at the same time to grind the flour, and the solid particles bonded in the flour are fully broken up to facilitate kneading. Net 28, the sieve 28 screens the...

Embodiment 2

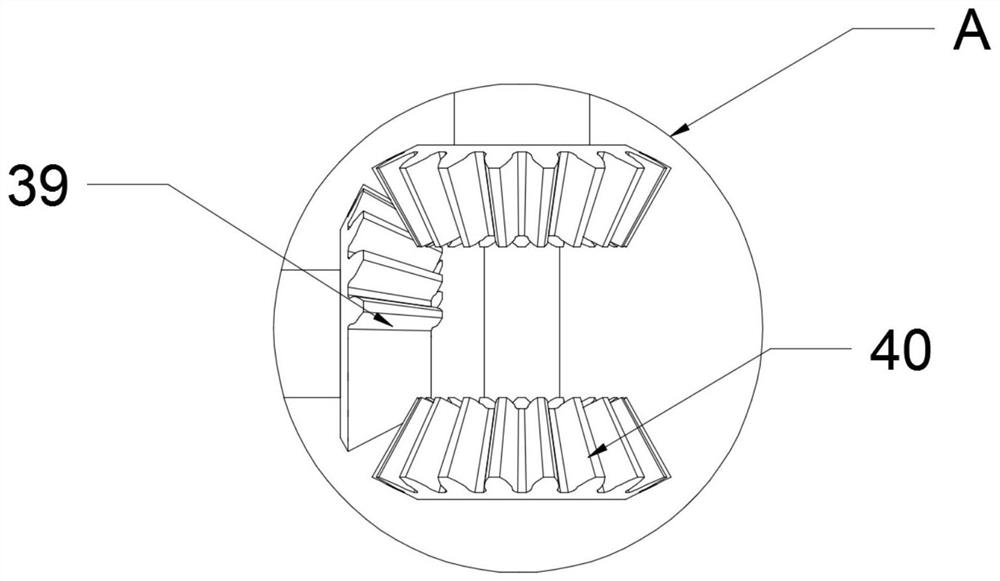

[0029] see Figure 1-5, on the basis of Embodiment 1, in order to automatically add water to the kneading box 35, a piston cylinder 27 is arranged on the left side of the upper surface of the support plate 15, and a piston 18 is arranged in the piston cylinder 27, and the top of the piston 18 is fixedly connected Piston rod 19, the top end of the piston rod 19 extends through the piston cylinder 27 and is fixedly connected to the push plate 21, the drive motor 3 41 is arranged above the push plate 21, and the output end of the drive motor 3 41 is fixedly connected to the oval wheel 23, so The ellipse wheel 23 is arranged directly above the push plate 21, and the left and right sides of the lower surface of the push plate 21 are symmetrically provided with telescopic springs 20, and the end of the telescopic spring 20 away from the push plate 21 is fixedly connected with the piston cylinder 27 top wall, so The water inlet pipe 16 is installed at the left end of the piston cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com