Titanium selecting agent and titanium selecting method

A technology for selecting titanium and reagents, applied in flotation, solid separation, etc., can solve the problems of high dosage of reagents, loss of ilmenite, and high cost, and achieve the effect of less dosage of reagents, less dosage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

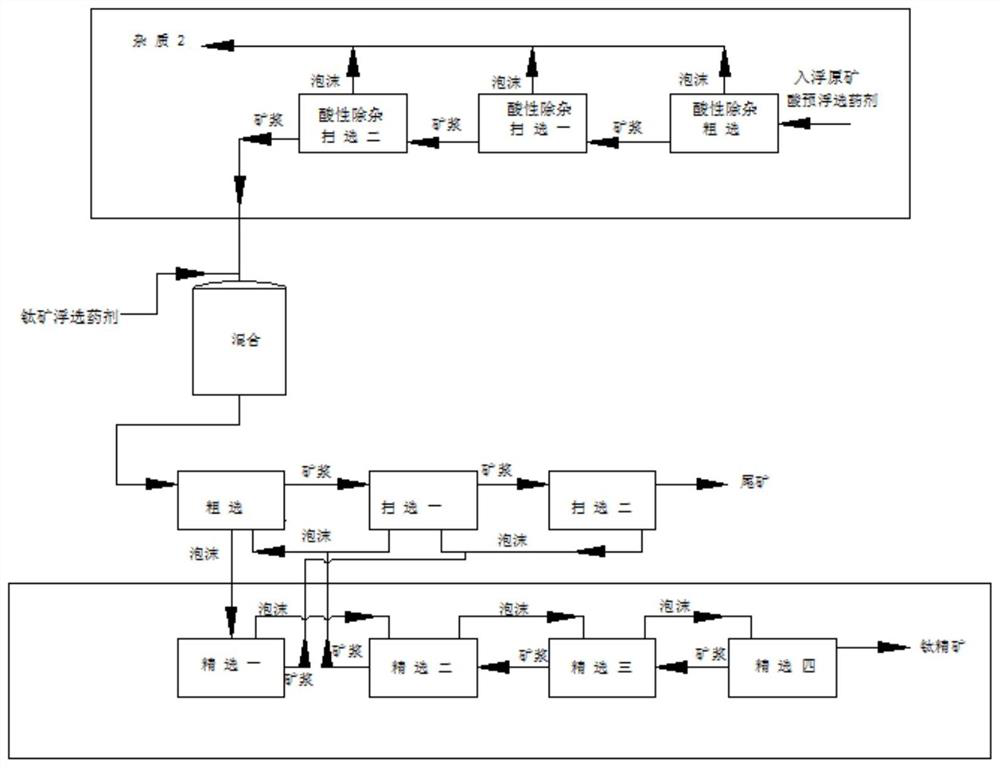

[0062] like figure 1 As shown, put 600g TiO 2 Add water to the raw ore with a grade of 18.92% to prepare a titanium-containing slurry with a concentration of 55%, and mix it with acid flotation agents: 0.12g fenugreek, 0.048g 2# oil, and 12g of 5% dilute sulfuric acid, and the pH is less than 7 Under acidic conditions, acidic impurity removal roughing, acidic impurity removal sweeping 1, and acidic impurity removal sweeping 2 are carried out sequentially, and the foam products of acidic impurity removal roughing, acidic impurity removal sweeping 1, and acidic impurity removal sweeping 2 are used as Impurities are discarded, and the pulp of acidic impurity removal roughing and acidic impurity removal sweeping one enters acidic impurity removal sweeping one, acidic impurity removal sweeping two, acidic impurity removal sweeping two pulp and 0.5g diesel oil, 0.4g containing 15wt Component B of % oxalic acid, 15wt% sulfamic acid and 70wt% sodium fluorosilicate was mixed for 0.5m...

Embodiment 2

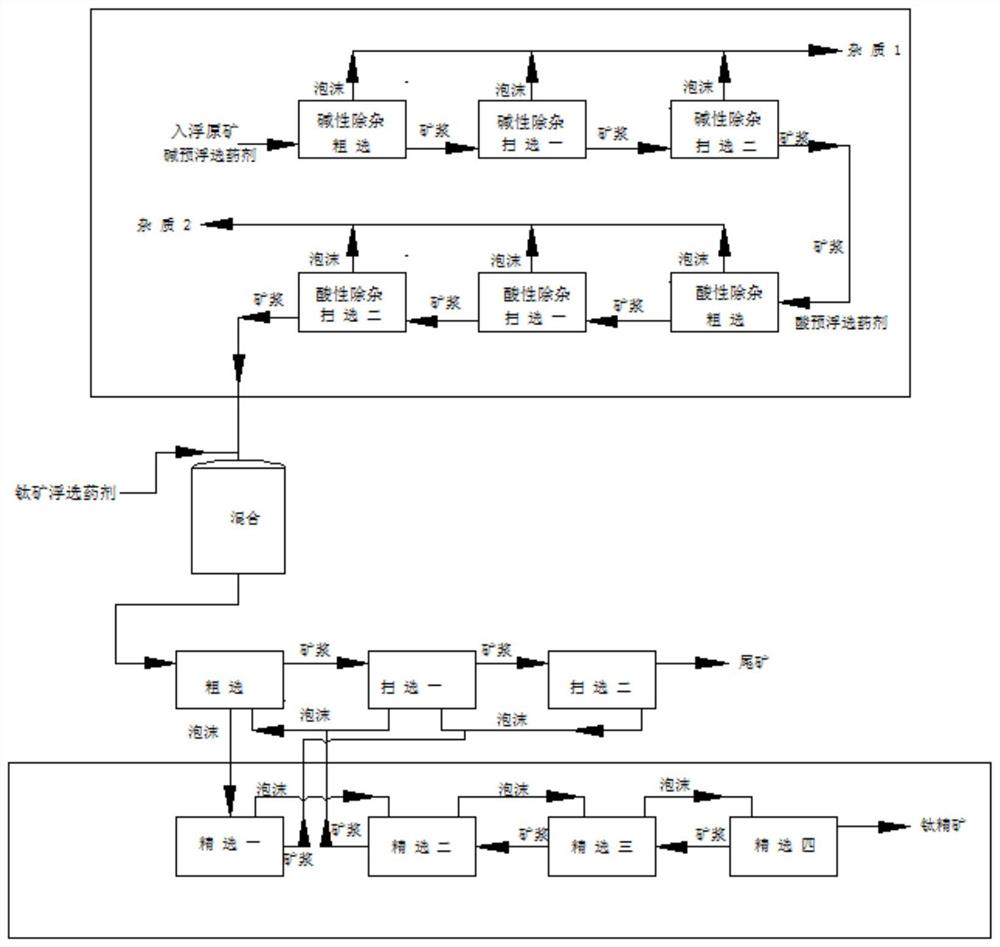

[0065] like figure 2 As shown, put 600g TiO 2 The raw ore with a grade of 18.92% is added with water to form a titanium-containing slurry with a concentration of 45%, and mixed with alkaline flotation reagents: 0.12g fenugreek, 0.048g 2# oil, 1g10% sodium hydroxide, the pH is greater than Under the alkaline condition of 7, carry out alkaline impurity removal rough selection, alkaline impurity removal sweeping one, and alkaline impurity removal sweeping two in sequence. The foam product of impurity removal and sweeping second is discarded as impurities, and the ore pulp of alkaline impurity removal roughing and alkaline impurity removal and sweeping first enters alkaline impurity removal and sweeping first, alkaline impurity removal and sweeping second, and alkaline impurity removal After the ore pulp of sweeping second is mixed with acid flotation agent 0.12g butyl xanthate, 0.048g 2# oil, 12g5% sulfuric acid, acidic impurity removal roughing, acidic impurity removal sweepin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com