Protection type multi-angle welding device for steel machining

A welding device and multi-angle technology, which is applied in the field of steel processing and welding, can solve problems that affect welding accuracy, cannot meet the needs of multi-angle welding processing, and affect the welding effect of protective steel processing, so as to improve welding accuracy and avoid continuous heat. Cumulative, Guaranteed Accuracy and Integrity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

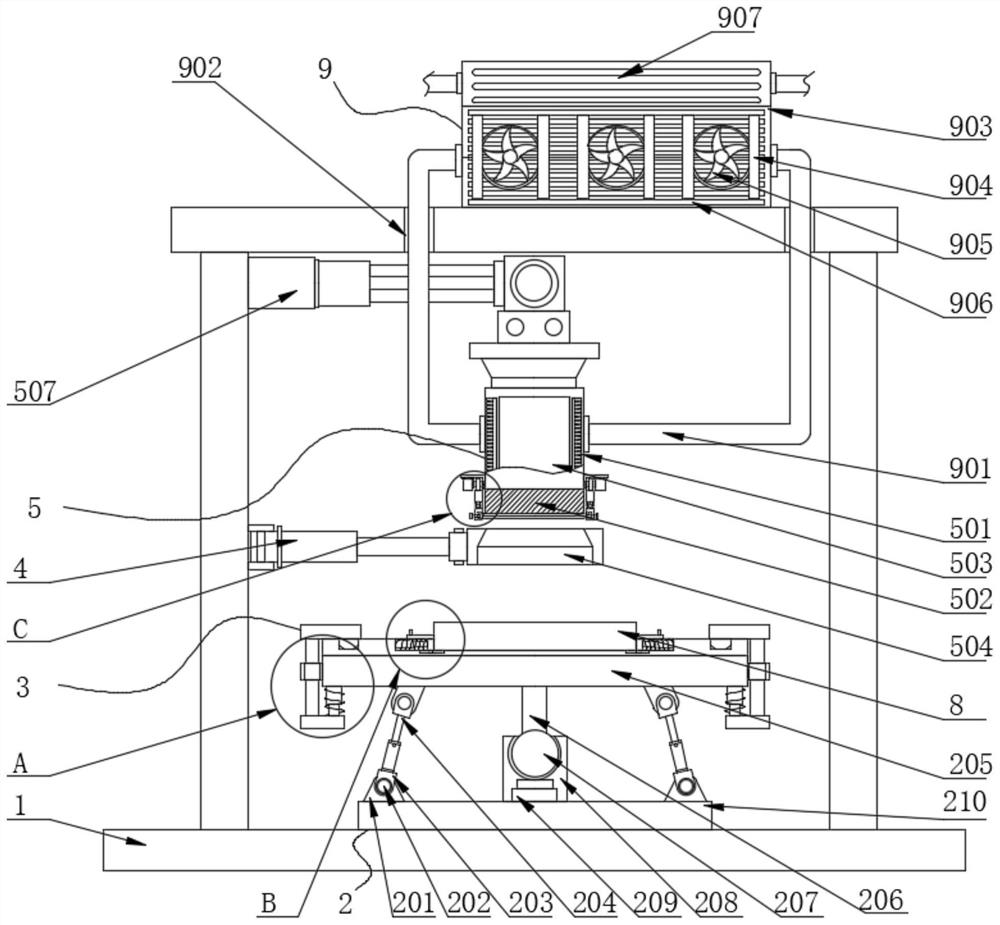

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

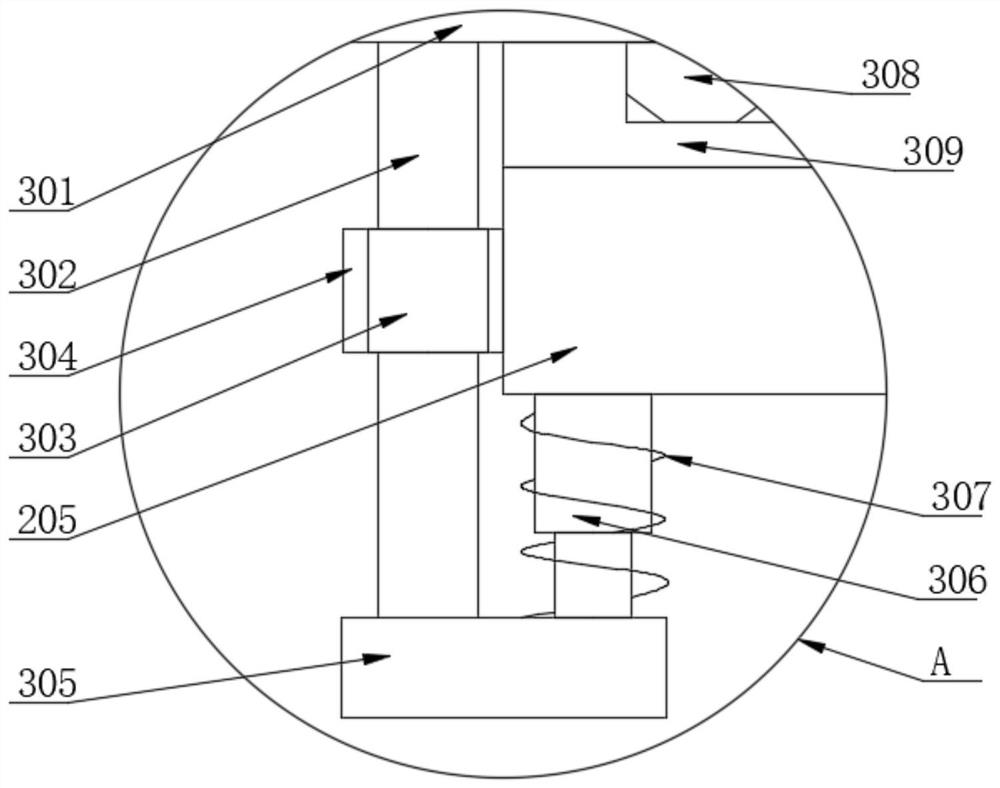

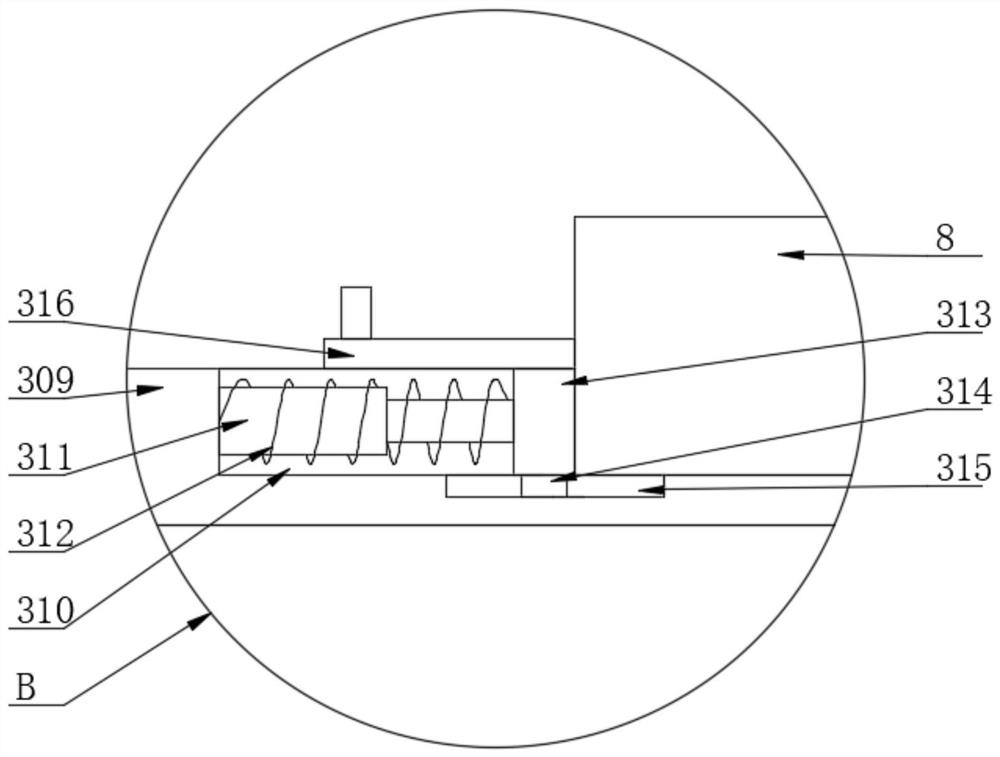

[0037] Such as Figure 1-8 As shown, the embodiment provides a protective multi-angle welding device for steel processing, including a frame 1, and the bottom of the frame 1 is fixedly connected with a steering mechanism 2, and both sides of the steering mechanism 2 are equipped with A clamping mechanism 3, a laser welding mechanism 5 is provided on one side of the inner cavity of the frame 1, a cleaning mechanism 6 is connected to the bottom side of the laser welding mechanism 5, and a cooling mechanism 9 is connected to the top side of the laser welding mechanism 5 , the cooling mechanism 9 is located on the top of the frame 1, and the openings on both sides of the frame 1 are provided with damper mechanisms 7;

[0038] The steering mechanism 2 includes a base 210 and a fixed base 205, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com