A control system and control method for a cloth palletizing robot based on behavior cloning

A technology of palletizing robot and control method, which is applied in the control system and control field of cloth palletizing robot based on behavior cloning, can solve the problems of slowing down production speed, manpower of the mechanical arm, time cost, inability to obtain position and posture, etc., to achieve Increase the stacking accuracy and realize the effect of real-time processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

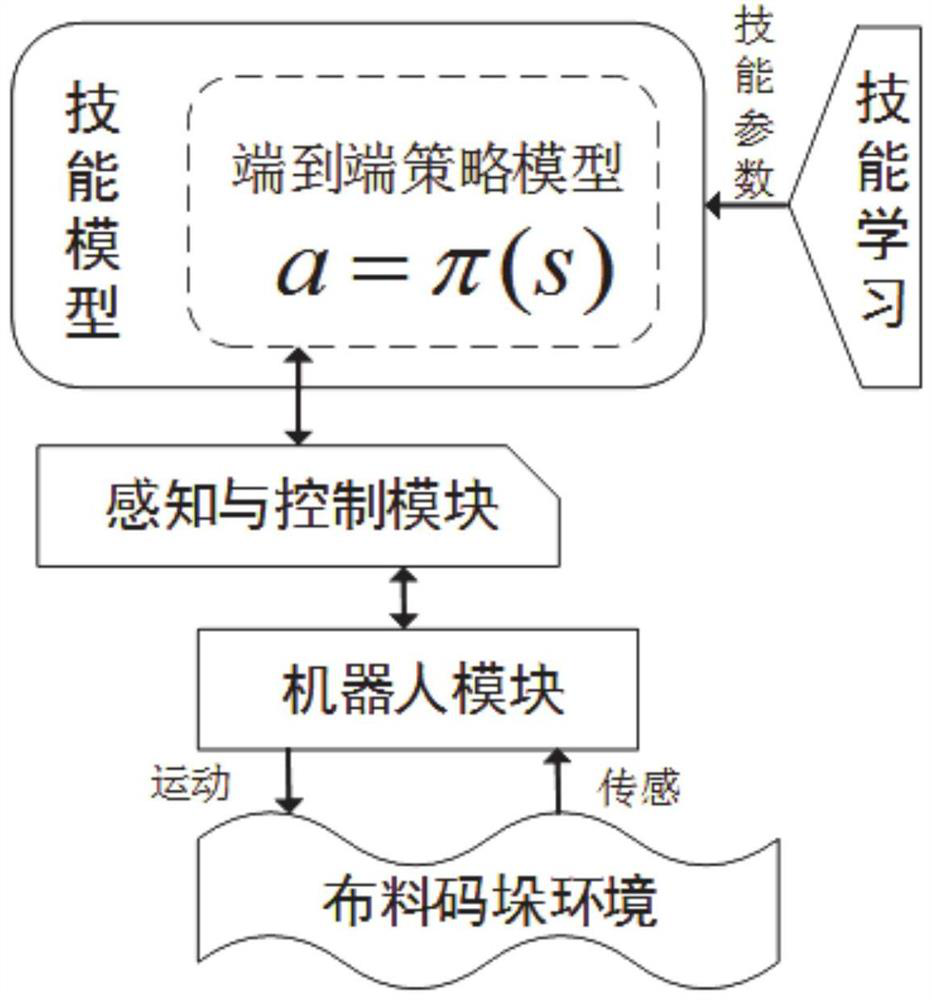

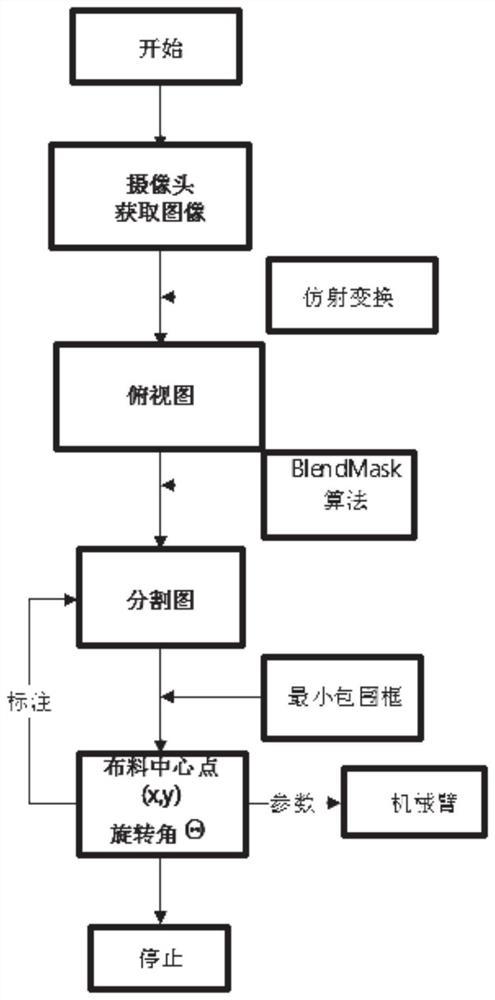

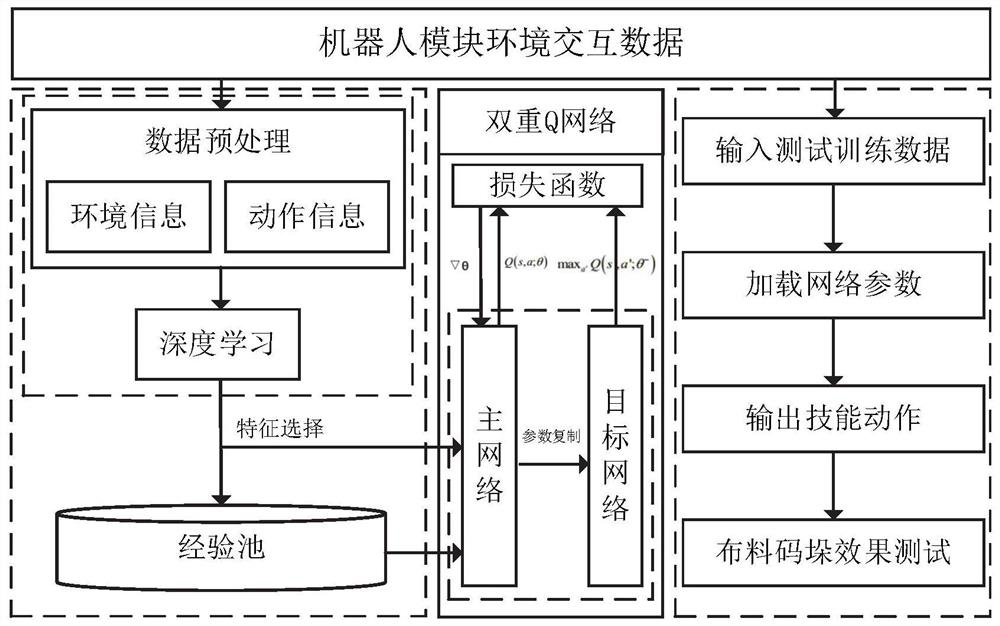

[0044] Embodiment 1 of the present invention provides a method for controlling a cloth palletizing cloud-based robotic arm based on behavior cloning in a human-machine collaborative environment. Transform the three-dimensional real position of the area to be identified to a fixed position in the pixel coordinate system; obtain the cloth monomer in the area to be identified at the fixed position based on the instance segmentation algorithm; obtain the artificial fabric monomer in the area to be identified at the fixed position The moving track of the single fabric during the palletizing process; the moving track is encoded based on the behavior cloning algorithm to obtain the encoded information; the control instruction is obtained according to the encoded information, and the robotic arm of the robot is controlled to stack the individual fabric according to the control instruction.

[0045]Among them, the three-dimensional real position of the area to be recognized is obtained ...

Embodiment 2

[0086] The cloth palletizing robot control system based on the behavior cloning algorithm provided by Embodiment 2 of the present invention includes: a near-end image acquisition unit for collecting image information of the region to be identified and transmitting it to the position transformation unit; a position transformation unit for The three-dimensional real position of the area to be identified is transformed into a fixed position in the pixel coordinate system; the monomer recognition unit is used to obtain the cloth monomer in the area to be identified at a fixed position based on the instance segmentation algorithm; the near-end image acquisition unit is used to acquire Image information of artificially stacking cloth monomers in the area to be identified under a fixed position; movement track calculation unit; used to obtain the moving track of cloth monomers in the image information of artificial palletizing; encoding unit, used for behavior-based cloning The algori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com