Optical picking-up head and optical device

A technology of optical pickup and optical axis, applied in optical recording head, integrated optical head device, optics, etc., can solve the problems of lack of practicability and poor light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

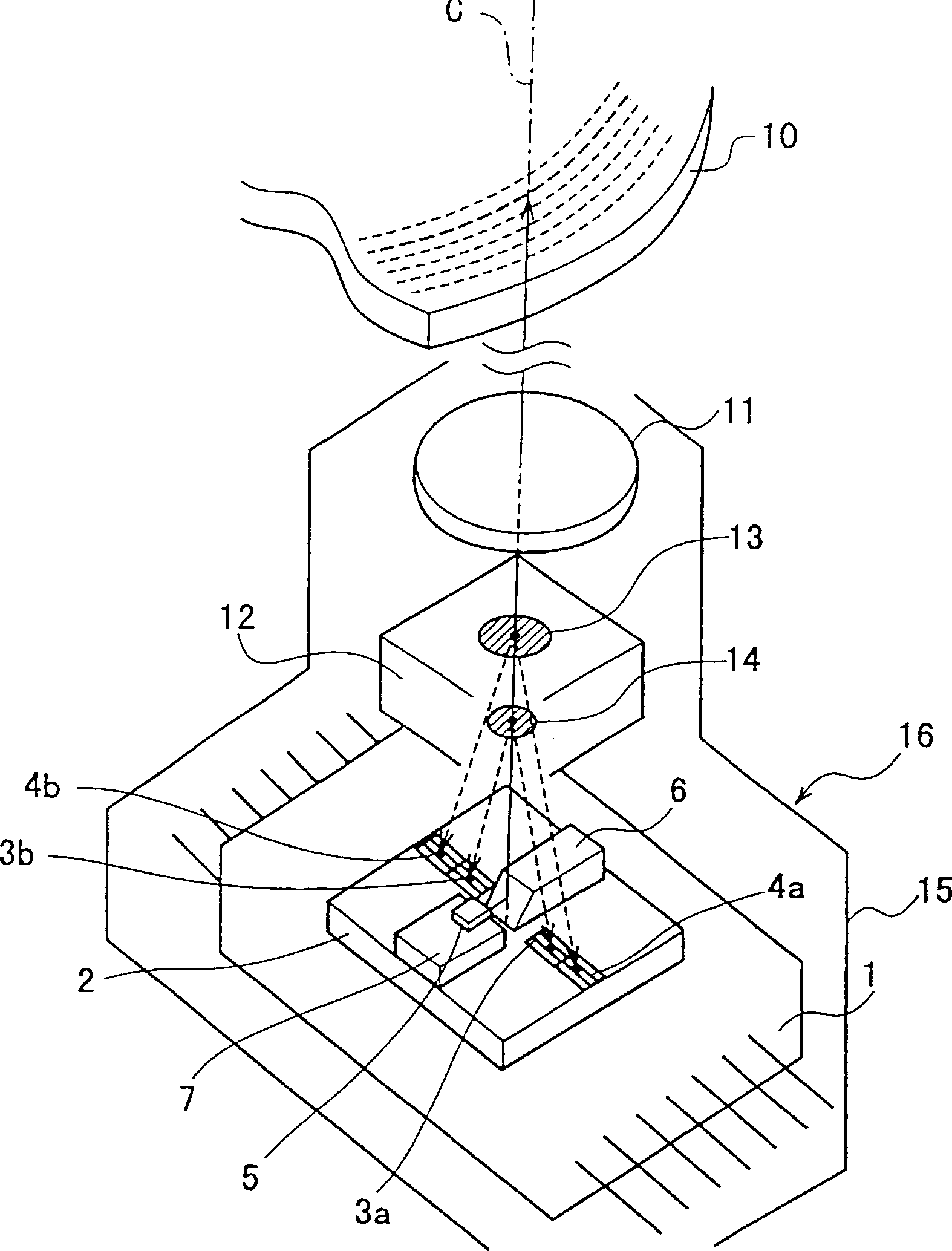

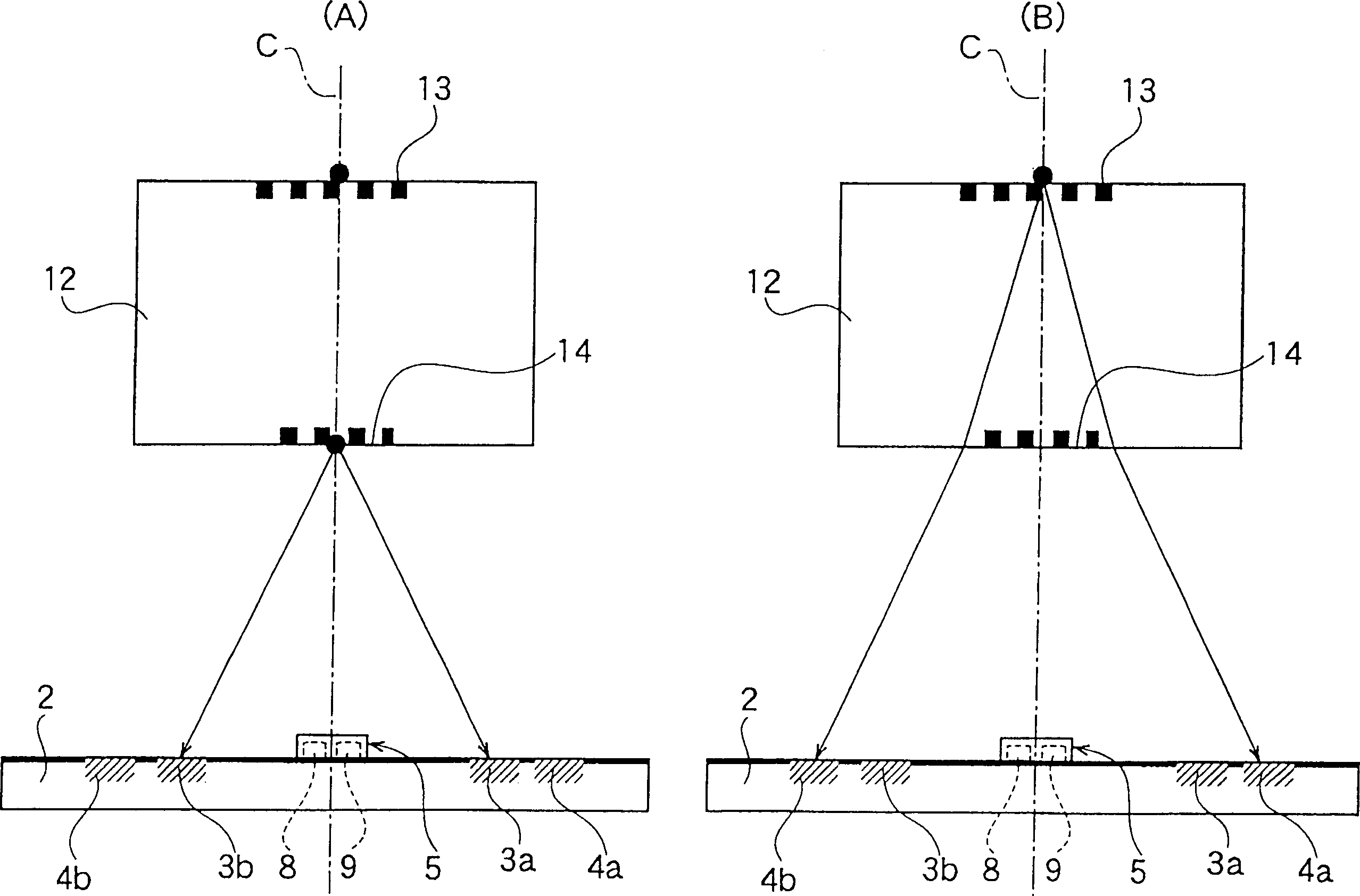

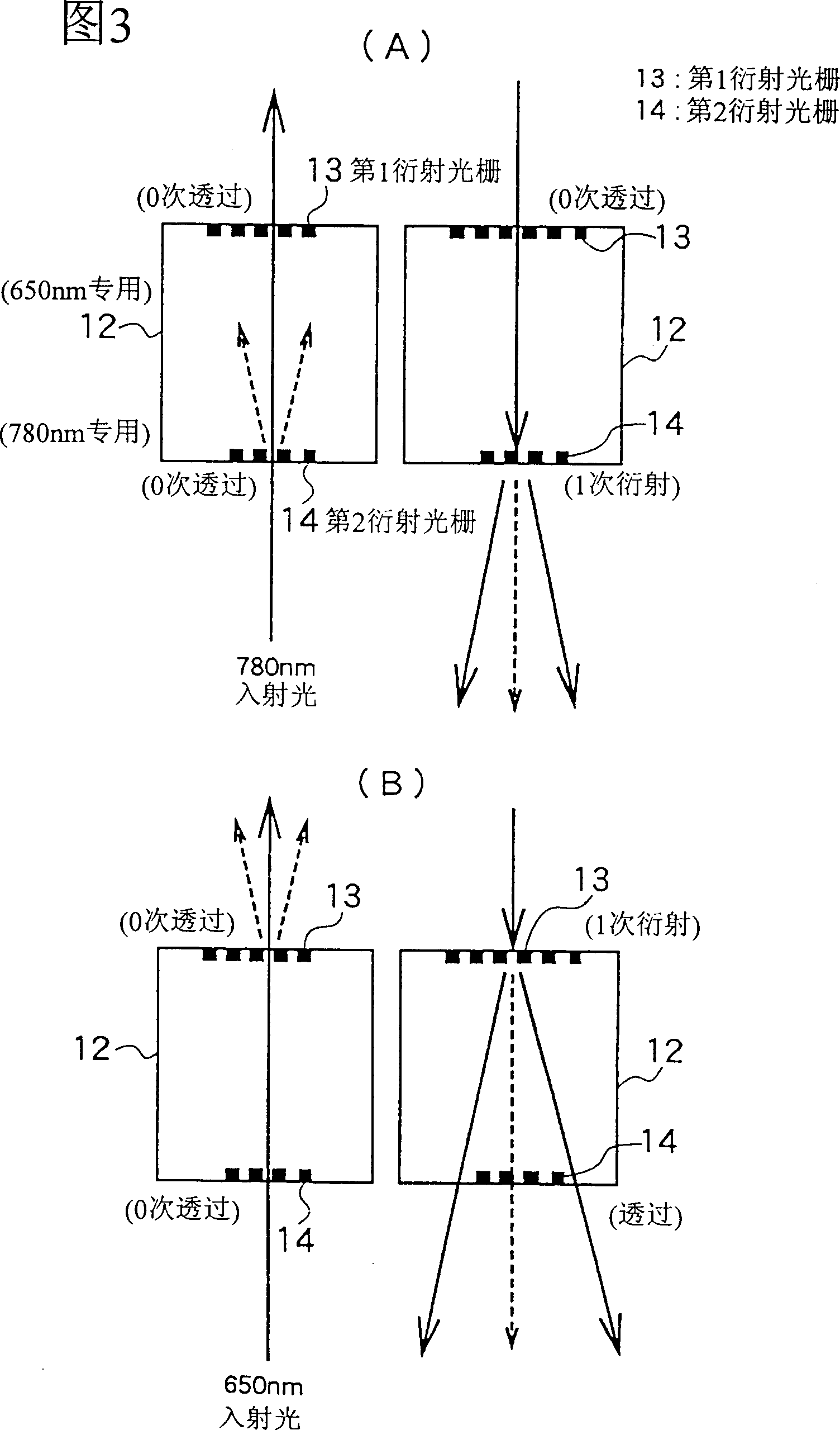

[0073] Embodiments of the present invention will be described below with reference to the drawings.

[0074] figure 1 one Figure 5 Shows the first embodiment of the present invention. figure 1 It is a simplified oblique view of the optical pickup head; figure 2 (A) represents the irradiation position of the emitted light of the first laser light source on the photosensitive element substrate; figure 2 (B) shows the irradiation position of the light emitted by the second laser light source on the photosensitive element substrate; FIG. 3(A) shows a state diagram in which the light emitted by the first laser light source is diffracted and transmitted by the first and second diffraction gratings ; Fig. 3 (B) shows that the output light of the second laser light source is diffracted and transmitted by the first and second diffraction gratings.

[0075] exist figure 1 - In FIG. 3, the photosensitive element substrate 2 is fixed on the wiring substrate 1, and four photosen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com