Composition for forming liquid crystal alighment film and liquid crystal display element

A technology of liquid crystal display elements and liquid crystal alignment films, which is applied in coatings, instruments, organic chemistry, etc., can solve the problems of poor viewing angle dependence and achieve the effects of wide viewing angle, high quality, and high aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0215] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited by these examples. In addition, various measurements in Examples, comparative synthesis examples, and comparative examples were performed by the following methods.

[0216] -Measurement of imidization rate of polyimide polymer-

[0217] Dissolve polyimide polymer in deuterated dimethyl sulfoxide, and measure at room temperature with tetramethylsilane as reference substance 1 H-NMR (400 MHz) was obtained by the following formula (i).

[0218] Formula (i) imidization rate (%)={1-(A 1 / A 2 )×α}×100

[0219] A 1 : Peak area (10-11ppm) of the proton derived from the NH group in the polymer precursor (polyamic acid)

[0220] A 2 : Peak area derived from protons derived from aromatic rings (7-8ppm)

[0221] α: The number of protons derived from the aromatic ring relative to one proton of the NH group in the polymer precursor (polyamic acid)

[...

Synthetic example 1

[0228] Synthesis Example 1 Synthesis of 2,4-dinitrophenylethyl acetate (2,4-DNEA)

[0229] 182 mL of 97% concentrated sulfuric acid (manufactured by Wako Pure Chemical Industries, Ltd.) was added to 225 g of fuming nitric acid (3.24 moles; manufactured by Wako Pure Chemical Industries, Ltd.) while stirring. After cooling the mixed acid with methanol / dry ice and keeping the internal temperature at -15 to -5°C, 59.1 g of phenylethyl acetate (PEA) was mixed while confirming the dispersibility of phenylethyl acetate (PEA) in the mixed acid. (0.36 mol; manufactured by Toyotama Fragrance Co., Ltd.) was slowly added dropwise to the mixed acid. After the dropwise addition, the cooling medium was changed to ice water, and the reaction was further carried out at 2-5° C. for 4 hours. After confirming the disappearance of phenethyl acetate (PEA) by thin-layer chromatography (TLC), the reaction liquid was poured into 740 g of ice water while stirring. Then, the solution was extracted wit...

Embodiment 1

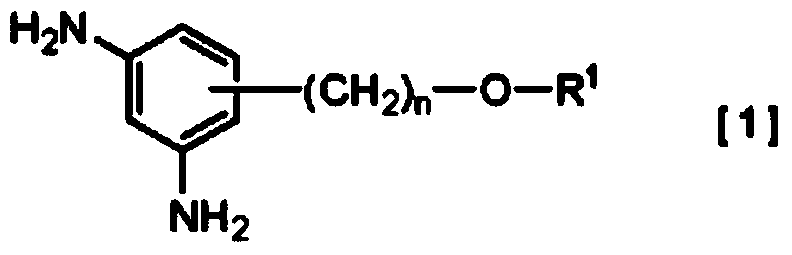

[0231] Example 1 Synthesis of 2,4-diaminophenethyl acetate (2,4-DAEA)

[0232] After dissolving 21.16 g (83.2 mmol) of 2,4-dinitrophenylethyl acetate (2,4-DNEA) in 100 mL of methanol, 1.06 g of 5% by weight palladium / carbon was added under a nitrogen atmosphere, and at room temperature, The reaction (reduction reaction) was carried out by hydrogen gas under normal pressure conditions for 24 hours. After confirming the disappearance of 2,4-dinitrophenylethyl acetate (2,4-DNEA) by TLC, the palladium / carbon in the reaction solution was removed by filtration, and then, after concentrating the solution under reduced pressure, it was analyzed by silica gel column chromatography. The residue was concentrated for purification. Ethyl acetate (13 mL) was added to 11.46 g of the obtained crude crystals, and the crude crystals were dissolved by heating to 55° C. Then, n-hexane (35 mL) was slowly added to the solution to precipitate crystals. The precipitated crystals were filtered, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com