Heat treatment process for connecting rod

A process and connecting rod technology, applied in the field of connecting rod heat treatment process, can solve the problems of inability to ensure uniform movement, prolong the heat treatment processing time, affect the mechanical properties of the workpiece, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

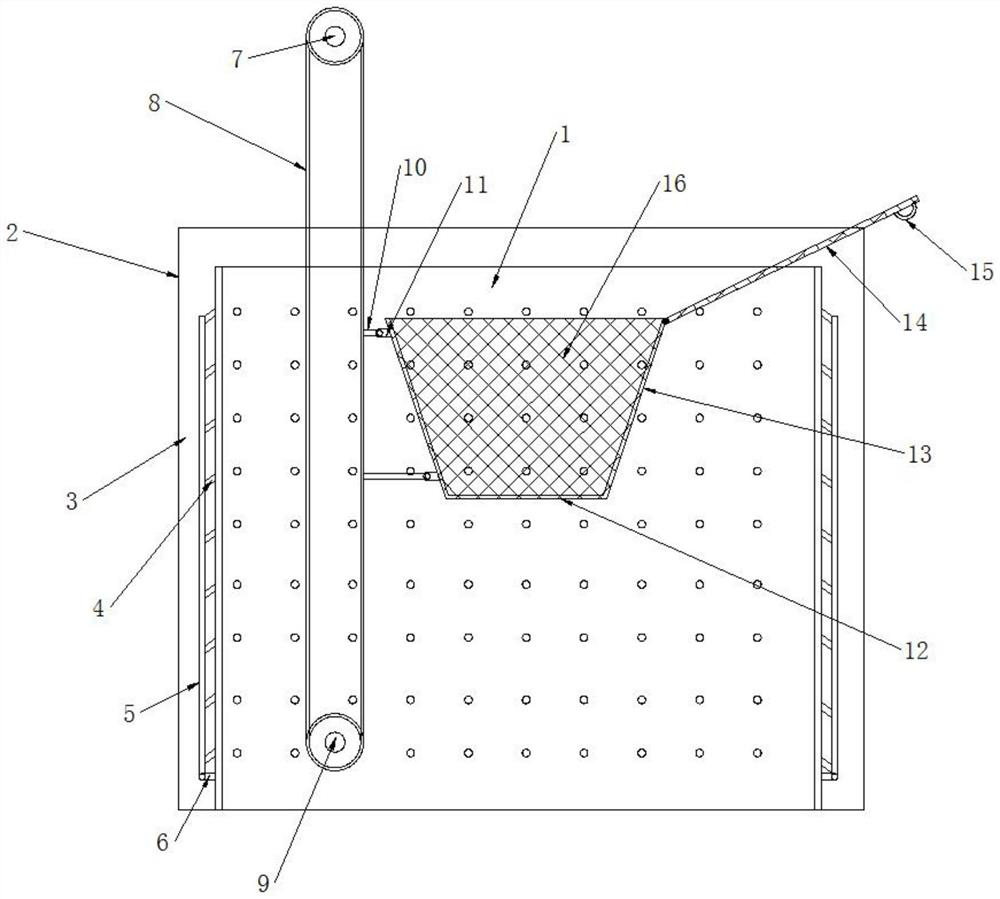

[0047] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0048] like figure 1 As shown, the connecting rod heat treatment process includes the following steps:

[0049] S1: Pre-circulate the water in the cooling tank 1;

[0050] S2: Set the heating temperature and holding time for the quenching furnace, and process the workpiece;

[0051] S3: Take out the workpiece and put it into the cooling tank 1, and drive the workpiece to reciprocate vertically at a constant speed through the support platform 12;

[0052] S4: Control the quenching residual temperature, and after the workpiece is cooled to room temperature, perform hardness testing;

[0053] S5: put the workpiece i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com