Channel steel-concrete composite beam and manufacturing method thereof

A technology of concrete and channel steel, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of heavy welding workload and low bearing capacity of composite beams, and achieve the effect of strong bearing capacity, simple structure and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

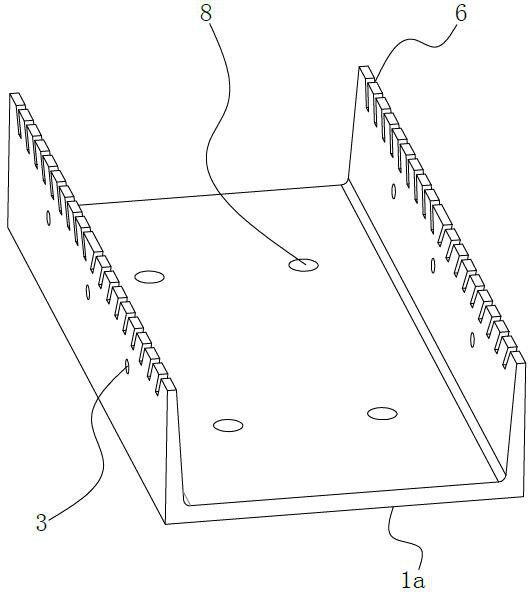

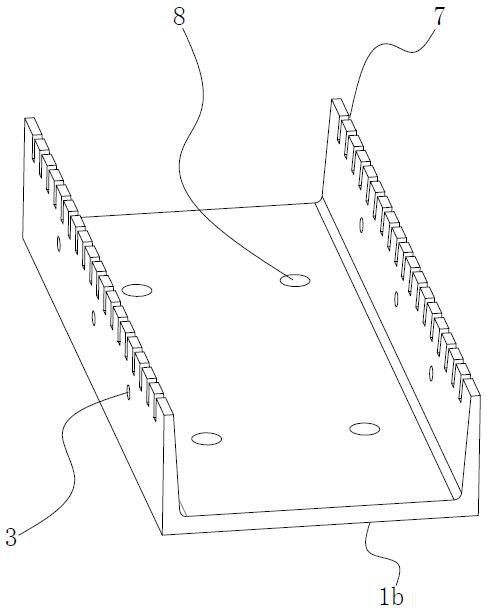

[0046] See Figure 1-2 As shown, in this embodiment, the oblique notch 6 is set at the top of the side plate of the outer beam 1a, and correspondingly, the vertical notch 7 is set at the top of the side plate of the inner beam 1b, and is located at the oblique front half of the side plate of the outer beam 1a. The direction of inclination toward the notch 6 is not the same as that of the oblique notch 6 located at the rear half of the side plate.

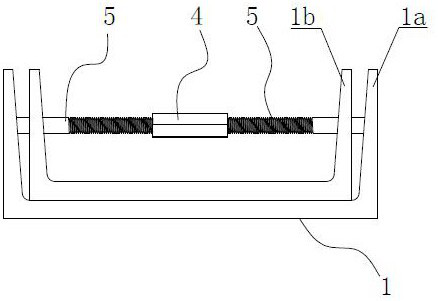

[0047] Further, in this embodiment, see Figure 3-5 , the threaded sleeve 4 is hexagonal as a whole, and the advantage of designing the threaded sleeve 4 as a hexagonal prism is: firstly, it can be easily screwed, and secondly, after the threaded sleeve 4 is wrapped by concrete, it can better prevent threading Socket 4 is loose. Wherein, a screw hole is provided along the axial direction of the threaded sleeve 4, and the threaded sleeve 4 is fixedly connected with the serial ribs 5 located on the left and right sides through the s...

Embodiment 2

[0052] See Figure 6 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the top end of the side plate of the inner beam 1b is lower than the top end of the side plate of the outer beam 1a, so that the vertical notch 7 at the top of the side plate of the inner beam 1b can be opened The depth is designed to be equal to the diameter of the reinforcing bar 2a or slightly darker than the diameter of the reinforcing bar 2a, so that the reinforcing bar 2a is placed. The structure of other parts of this embodiment and the manufacturing method of the composite beam are similar to those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] See Figure 8 As shown, the difference between this embodiment and Embodiment 1 is mainly that the vertical notch 7 is set at the top of the side plate of the outer beam 1a, and the oblique notch 6 is set at the top of the side plate of the inner beam 1b. The structure of other parts of this embodiment and the manufacturing method of the composite beam can also be similar to that of Embodiment 1. It should be noted that in this embodiment, the oblique notch 6 is not limited to Figure 8 In the opening method shown, on the premise that the oblique notches 6 are opened at the top of the side plate of the inner girder 1b, it is actually a better solution to make all the oblique notches 6 have the same inclination direction, so that the bridge deck 2 is thicker and It will be more convenient for construction and installation when a built-in steel cage is required. The specific construction method is as follows: firstly, the inner beam 1b and the outer beam 1a are made res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com