Tunnel lining type double-reaction-force-wall structure device for anti-seismic test and preparation method

A seismic test and tunnel structure technology, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of high cost of large-scale reaction wall structure system, huge construction investment, inconvenient for common universities and research institutes, etc. The effect of infrastructure cost, reducing infrastructure investment and saving huge amount of money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

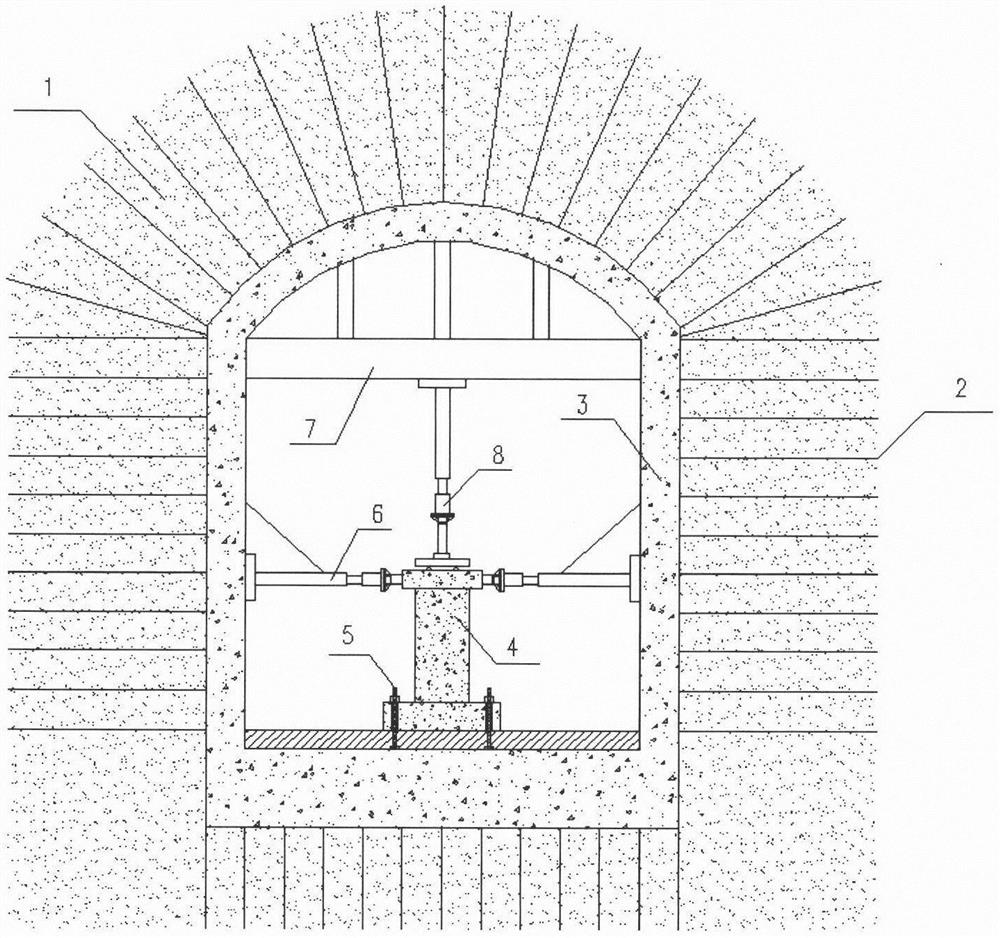

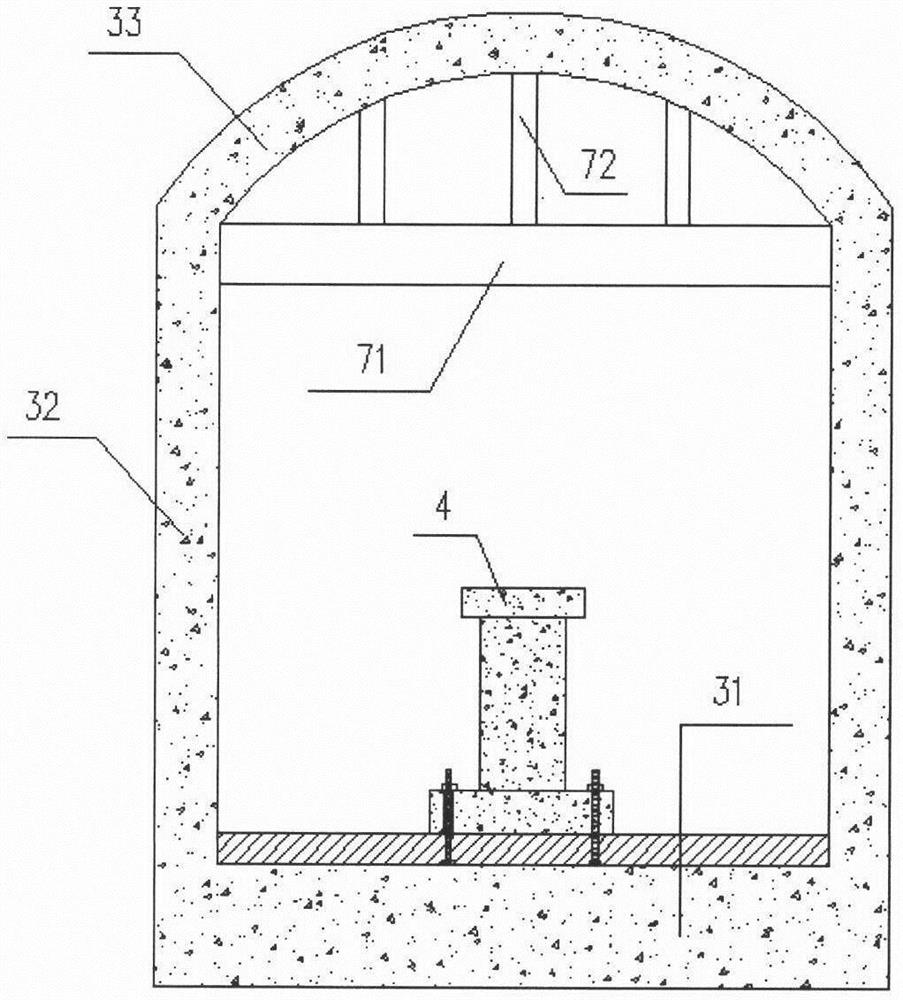

[0044] The present invention is a tunnel lining type double reaction wall structure device for earthquake resistance test, comprising original tunnel structure 1, tunnel rock bolt group 2, straight wall arch lining type double reaction wall frame structure 3, seismic test member 4, The ground anchor system 5, horizontal jack loading system 6, reaction beam system 7 and vertical jack loading system 8 are characterized in that: tunnel rock anchor groups 2 are set around the original tunnel structure 1, straight wall arch lining type double reverse The surroundings of the force wall frame structure 3 are embedded in the original tunnel structure 1, and the tunnel rock bolt group 2 is anchored in the straight wall arch lining type double reaction force wall frame structure 3. The straight wall arch lining type double reaction force wall The wall frame structure 3 is composed of a reaction base plate 31, a vertical reaction wall 32 and a top arch ring 33, and the seismic test member...

Embodiment 2

[0051] The preparation method of the above-mentioned tunnel lining type double reaction wall structure device for earthquake resistance test is characterized in that it comprises the following steps:

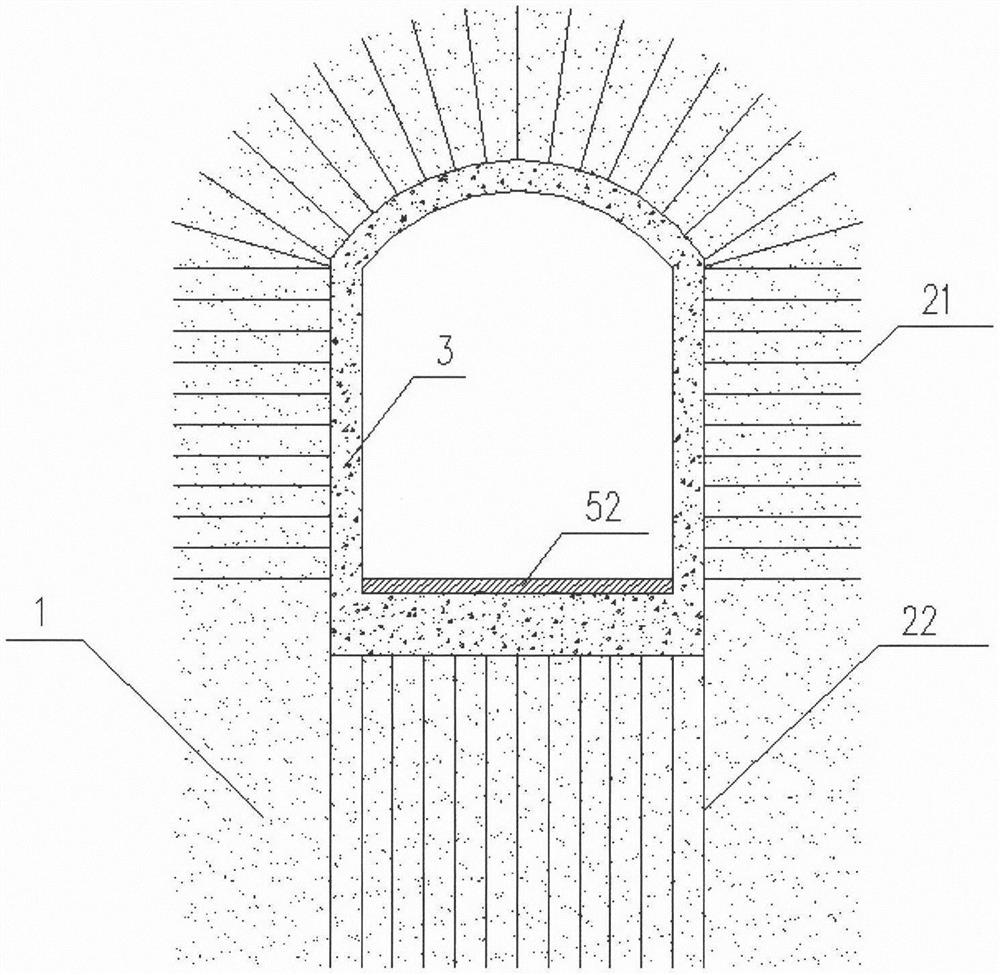

[0052] Step 1) Select the abandoned tunnel, excavate the surrounding walls of the original tunnel structure 1 according to the design drawings, and construct the surrounding rock short anchor rods 21 at the vertical side walls and the top arch circle of the original tunnel structure 1, Construction bottom plate long bolt 22 at the bottom plate of the tunnel, forming tunnel rock bolt group 2;

[0053] Step 2) According to the construction method of the tunnel lining structure, adopt the form of steel concrete structure, construct the reaction force floor 31, the vertical reaction force wall 32 and the top arch ring 33 in sequence, and the tail of the tunnel rock bolt group 2 is fixed to the straight wall arch lining Within the structure, a straight-wall-arch-lined double-reaction...

Embodiment 3

[0060] An abandoned military cavern, the original cavern lining is a straight wall arch lining structure, the net width of the original lining is 10 meters, the net height is 12 meters, the net height of the vertical side walls is 10 meters, and the net sag of the top arch circle is 2.5 meters , it is planned to carry out secondary development and utilization, and the 55-meter length in the depth of the abandoned military cavern is selected, and it is proposed to be rebuilt into a seismic laboratory with a tunnel-lined double-reaction wall structure.

[0061] The surrounding rock of the abandoned military cavern is a Type VI hard rock surrounding rock structure. The surrounding rock is slightly affected by the geological structure, the joints are not developed, and there is no weak surface or interlayer; shape, the overall structure, the surrounding rock is stable, and there is no collapse.

[0062]Excavate the surrounding walls of the original tunnel-style military warehouse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com