Manufacturing method of heating cigarette aroma enhancement rolling method sheet

A manufacturing method and technology of rolling method, which are applied in the directions of tobacco, tobacco preparation, and tobacco processing, can solve the problems of insufficient content of aroma substances and difficulty in rolling, and achieve the advantages of improving aroma substances, avoiding temperature rise and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a special sheet for heating cigarettes, comprising the following steps:

[0036] (1) Leaf group formula design: The leaf group formula selects tobacco leaves of different flavor types in Yunnan, Sichuan, Hubei, Chongqing, Henan and Hunan. Sweet and strong, long-lasting fragrance, high concentration, strong energy, and clean aftertaste, reflecting the distinct characteristics of Luzhou-flavor style.

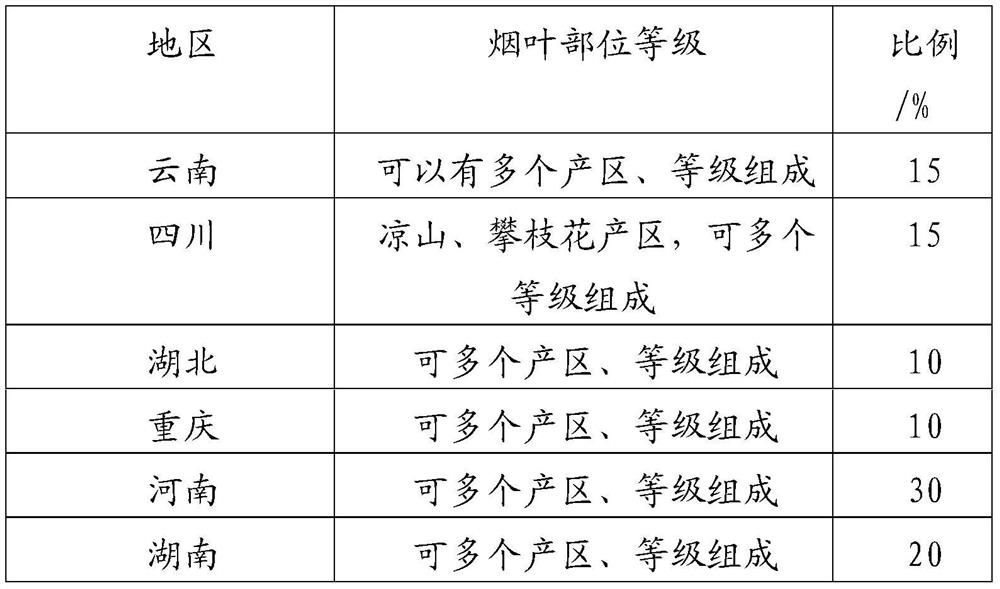

[0037] Table 1 leaf group formula

[0038]

[0039] (2) Loosening and regaining moisture: According to the raw material formula, after unpacking and slicing the smoked slices, they are sent to the dampening machine for loosening and dampening treatment. The hot air of the dampening machine is 80°C, and the moisture content at the outlet is 15.5%. The lower temperature prevents loosening and dampening The loss of low molecular volatile substances in the process.

[0040] (3) Shred: Send the temporary storage process into the shredder to shred, the...

Embodiment 2

[0059] A method for preparing a special sheet for heating cigarettes, comprising the following steps:

[0060] (1) Leaf group formula design: The leaf group formula selects tobacco leaves of different flavor types in Yunnan, Sichuan, Hubei, Chongqing, Henan and Hunan. Sweet and strong, long-lasting fragrance, high concentration, strong energy, and clean aftertaste, reflecting the distinct characteristics of Luzhou-flavor style.

[0061] Table 4 leaf group formula

[0062]

[0063] (2) Loosening and regaining moisture: According to the raw material formula, after unpacking and slicing the smoked sheets, they are sent to the moisture regaining machine for loosening and moisture regaining treatment. The hot air of the moisture conditioning machine is 75°C, and the moisture content at the outlet is 16.0%. The lower temperature prevents loosening and regaining moisture The loss of low molecular volatile substances in the process;

[0064] (3) shred: send the temporary storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com