A method for preparing reconstituted tobacco leaves by papermaking method

A technology for reconstituted tobacco leaves and papermaking method is applied in the field of preparation of reconstituted tobacco leaves by papermaking method to achieve the effects of reducing unpleasant smell, increasing nicotine content and improving sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

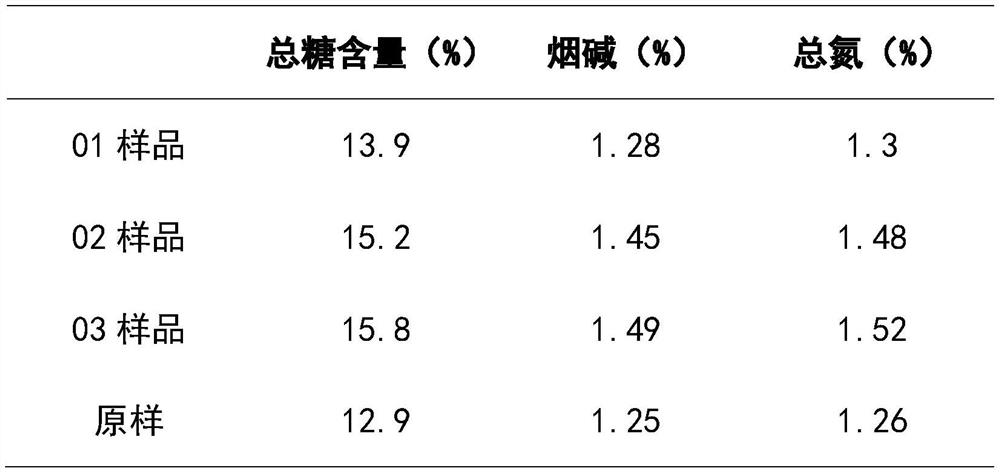

Embodiment 1

[0027] A method for preparing reconstituted tobacco leaves by the papermaking method, comprising the following steps: taking the dry pulp, and sequentially performing the steps of extraction, beating, papermaking, pressing at the wire part, drying, coating, rewinding and cutting; specifically, the steps are as follows :

[0028] S01, take an appropriate amount of white water 1L that is recycled in the pressing step of the mesh section, heat it to 100°C in the heating tank, heat-insulate it and keep it for later use;

[0029] S02, add 100g of polyhydroxy vegetable starch into the heating tank, dissolve in the above-mentioned white water, keep warm for 45 minutes, and make it partially hydrolyzed; after the heat preservation is completed, the white water for pulping is obtained;

[0030] S03, adding the above-mentioned flushing white water added with polyhydroxy vegetable starch into the headbox;

[0031] S04, the slurry mixture coming out of the headbox is dehydrated in the wi...

Embodiment 2

[0044] A method for preparing reconstituted tobacco leaves by the papermaking method, comprising the following steps: taking the dry pulp, and sequentially performing the steps of extraction, beating, papermaking, pressing at the wire part, drying, coating, rewinding and cutting; specifically, the steps are as follows :

[0045] S01, take an appropriate amount of white water recycled in the pressing step of the mesh section, heat it to 80°C in a heating tank, heat-insulate it and keep it for later use;

[0046] S02, add 150g polyhydroxy vegetable starch in heating tank, keep warm for 60min;

[0047] S03, adding the above-mentioned flushing white water added with polyhydroxy vegetable starch into the headbox;

[0048] S04, the slurry mixture coming out of the headbox is dehydrated in the wire pressing step and then dried in the drying step. After drying, the sheet tobacco is obtained, and then enters the coating step;

Embodiment 3

[0061] A method for preparing reconstituted tobacco leaves by the papermaking method, comprising the following steps: taking the dry pulp, and sequentially performing the steps of extraction, beating, papermaking, pressing at the wire part, drying, coating, rewinding and cutting; specifically, the steps are as follows :

[0062] S01, take an appropriate amount of white water recycled in the pressing step of the wire section, heat it to 120°C in a heating tank, heat-preserve it and keep it for later use;

[0063] S02, add 130g polyhydroxy vegetable starch in heating tank, keep warm for 50min;

[0064] S03, adding the above-mentioned flushing white water added with polyhydroxy vegetable starch into the headbox;

[0065] S04, the slurry mixture coming out of the headbox is dehydrated in the wire pressing step and then dried in the drying step. After drying, the sheet tobacco is obtained, and then enters the coating step;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com