Electronic atomization liquid capable of stably releasing cigarette fragrance and preparation method thereof

An electronic atomization and cigarette aroma technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of inconsistent nicotine content, unstable flavor, affecting consumer experience, etc., achieve good flavor, improve smoking satisfaction, The effect of three-dimensional network structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

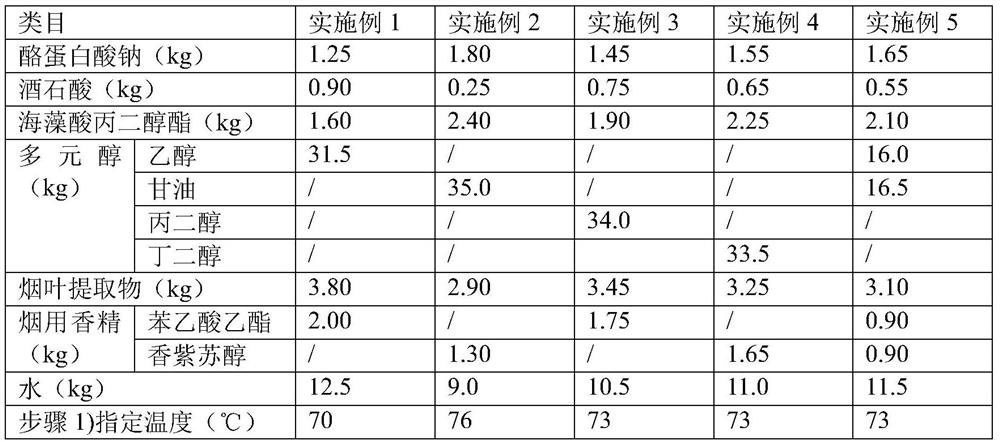

Embodiment 1-5

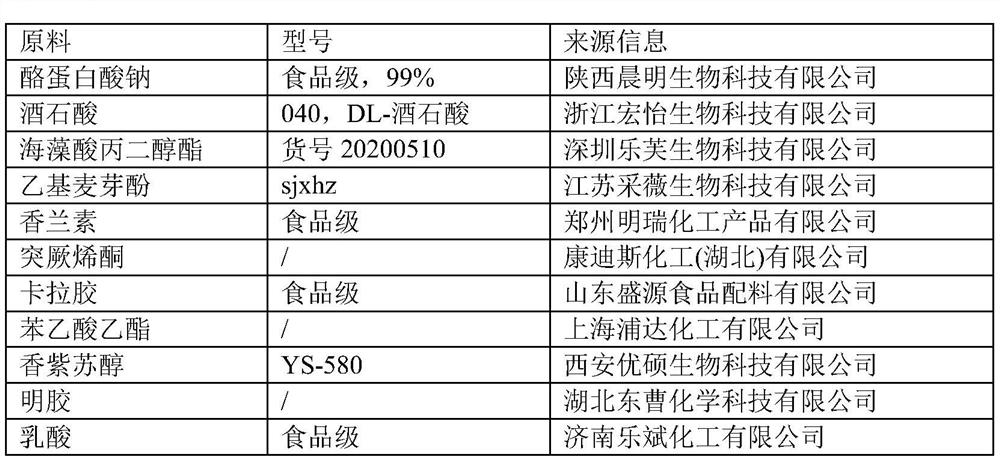

[0036] An electronic atomization liquid for stably releasing tobacco cigarettes, including sodium caseinate, tartaric acid, propylene glycol alginate, polyhydric alcohol, tobacco leaf extract, tobacco flavor and water.

[0037] Polyhydric alcohol is one or more in ethanol, glycerin, propylene glycol, butanediol.

[0038] The essence for tobacco is one or more of ethyl phenylacetate and sclareol.

[0039] A method for preparing an electronic atomization liquid, comprising the following steps:

[0040] Step 1): Sodium caseinate and propylene glycol alginate are put into water, stirred at the specified temperature and 25r / min until dissolved, and the base liquid is obtained.

[0041] Step 2): Maintaining the temperature and rotating speed, adding polyol to the base liquid, stirring for 6 minutes to obtain a mixed liquid.

[0042] Step 3): Keeping the temperature and rotating speed, adding tartaric acid, tobacco leaf extract and tobacco essence to the mixture, stirring until dis...

Embodiment 6

[0049] An electronic atomization liquid that stably releases cigarettes. The difference from Example 5 is that the weight ratio of ethanol to glycerin in the polyol is 1:0.6, that is, the input amount of ethanol is 20.31 kg, and the input amount of glycerin is 12.19 kg.

Embodiment 7

[0051] An electronic atomization liquid that stably releases cigarettes. The difference from Example 5 is that the weight ratio of ethanol to glycerin in the polyol is 1:0.8, that is, the input amount of ethanol is 18.06 kg, and the input amount of glycerin is 14.44 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com