Grinding and polishing device and method for optical cone

A polishing device and cone technology, applied in optical surface grinders, grinding/polishing equipment, devices for fixing grinding wheels, etc., can solve the problems of inappropriate conical surface polishing, and the processing level of components cannot meet high-precision comprehensive indicators, etc. Long service life, ensure consistency, and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

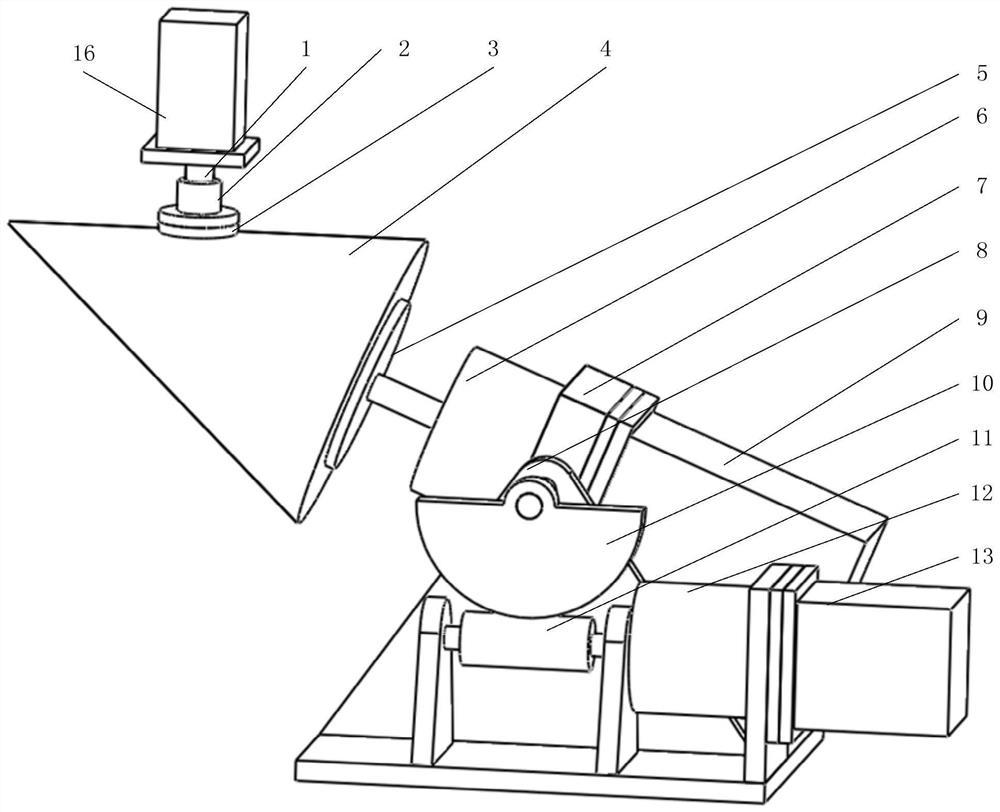

[0044] This embodiment discloses an optical conical grinding and polishing device, see attached figure 1 , which includes a support frame 8, a movable mechanism, a thimble 1, a flat polishing disc 2, and a polishing disc motor 16; the movable mechanism is installed on the support frame 8, and the movable mechanism has two degrees of freedom of movement: the first degree of freedom of end rotation, And the second degree of freedom that the center of rotation is perpendicular to the rotation axis of the end; the end of the movable mechanism is used to connect the cone to be processed; the thimble 1 is located in the plane where the rotation axis of the end of the movable mechanism moves in the second degree of freedom; the plane The polishing disc 2 is universally connected with the thimble 1 , the thimble 1 is driven by the polishing disc motor 16 , and the surface of the flat polishing disc 2 is provided with a polishing material layer 3 .

[0045] For specific implementation,...

Embodiment 2

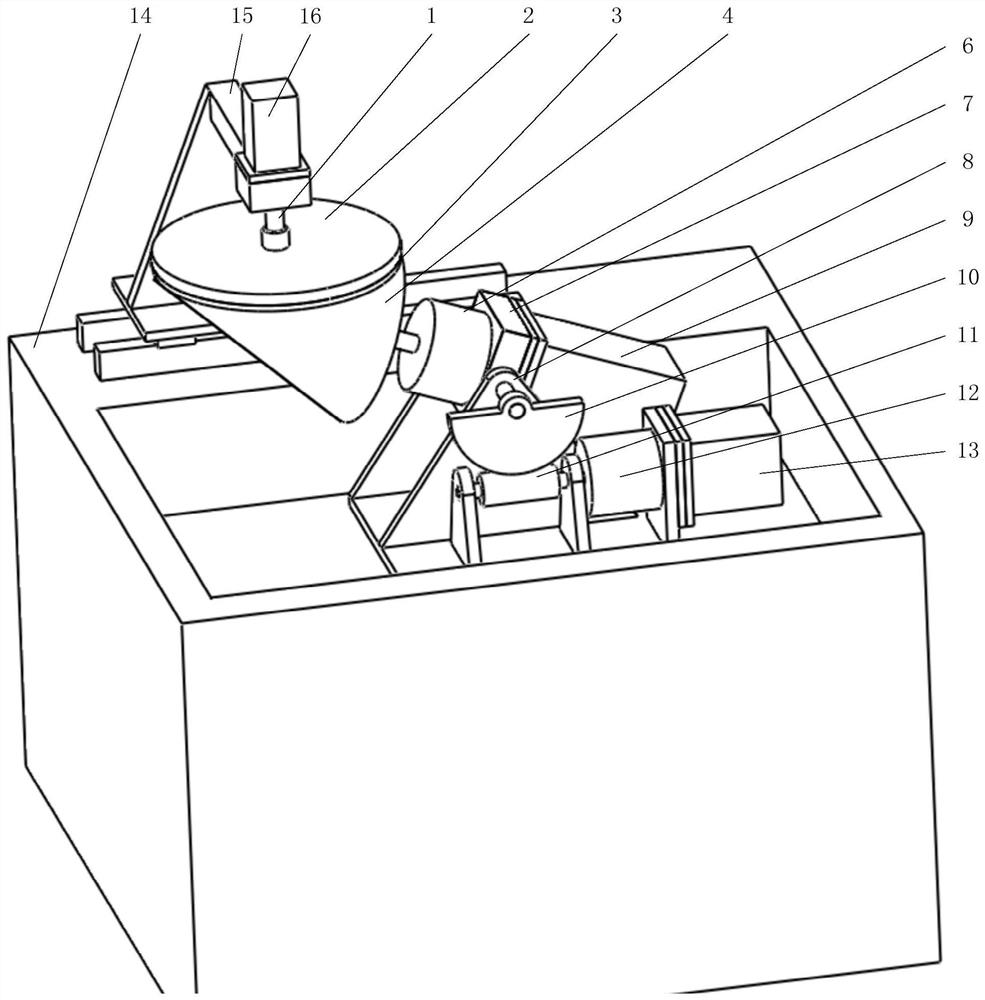

[0077] This embodiment discloses a grinding and polishing machine tool, such as figure 2 As shown, it includes a frame 14 and a kind of optical cone grinding and polishing device in the above-mentioned embodiment, the support frame 8 of the optical cone grinding and polishing device is installed on the frame 14, and the frame 14 is also provided with a polishing disc motor mounting shaft 15. The polishing disc motor 16 of the optical conical grinding and polishing device is installed on the polishing disc motor installation shaft 15. Obviously, the position of the polishing disk motor installation shaft 15 needs to correspond to the position of the installation support frame 8, so that finally the thimble 1 corresponds to the output shaft of the axial drive mechanism (ie the shaft end of the movable mechanism).

[0078]In one embodiment, the frame is a single-axis grinding and polishing machine frame, and the mounting shaft of the polishing disc motor is a swing shaft structu...

Embodiment 3

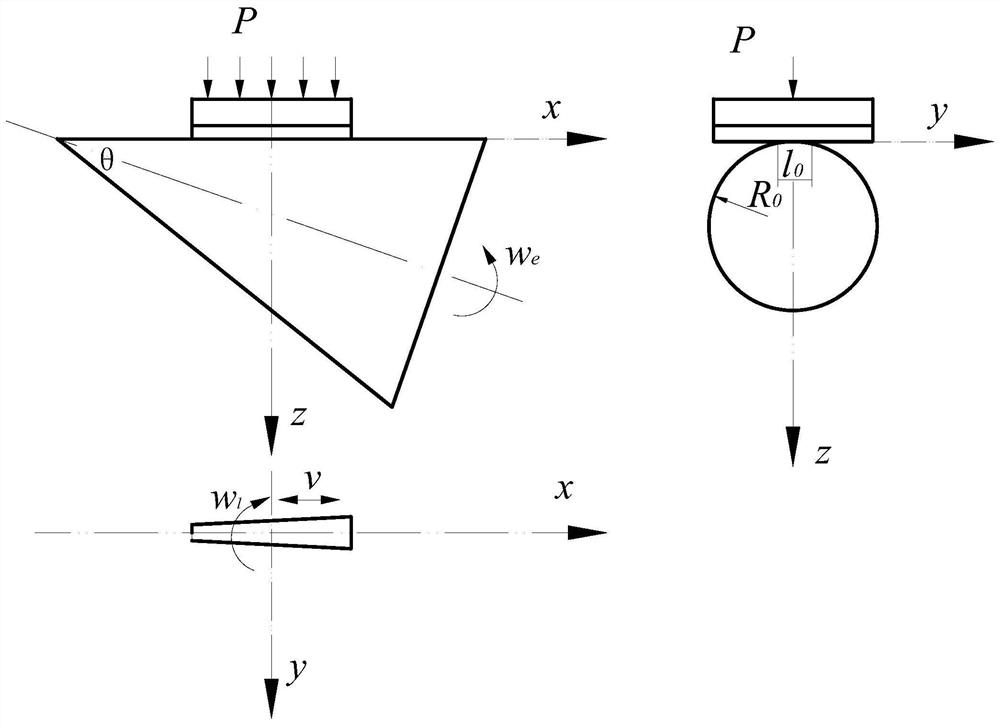

[0081] In an implementation example, such as figure 2 , for the case that the frame is a single-axis grinding and polishing machine frame, a method of fast polishing is designed by using the method of full-diameter polishing (the size of the polishing disc is equivalent to the size of the processed component), and the polishing disc is on the polishing disc. While rotating under the drive of the motor, it swings back and forth along the x-axis driven by the motor installation shaft (15). The swing center can be adjusted on the frame. The components rotate under the drive of the drive motor (16). The position, swing amplitude, speed, and component rotation speed realize component polishing and surface shape maintenance.

[0082] In another implementation example, for the case where the frame is a three-axis CNC machine tool, a method of precision modification control is designed by using sub-aperture polishing (the size of the polishing disc is much smaller than the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com