Hot floating type water surface oil stain adsorption floating disc

A kind of oily and floating technology on the surface of water, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problem of reducing the oil pollution adsorption efficiency on the surface of sewage, and achieve improved efficiency and improved The effect of absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

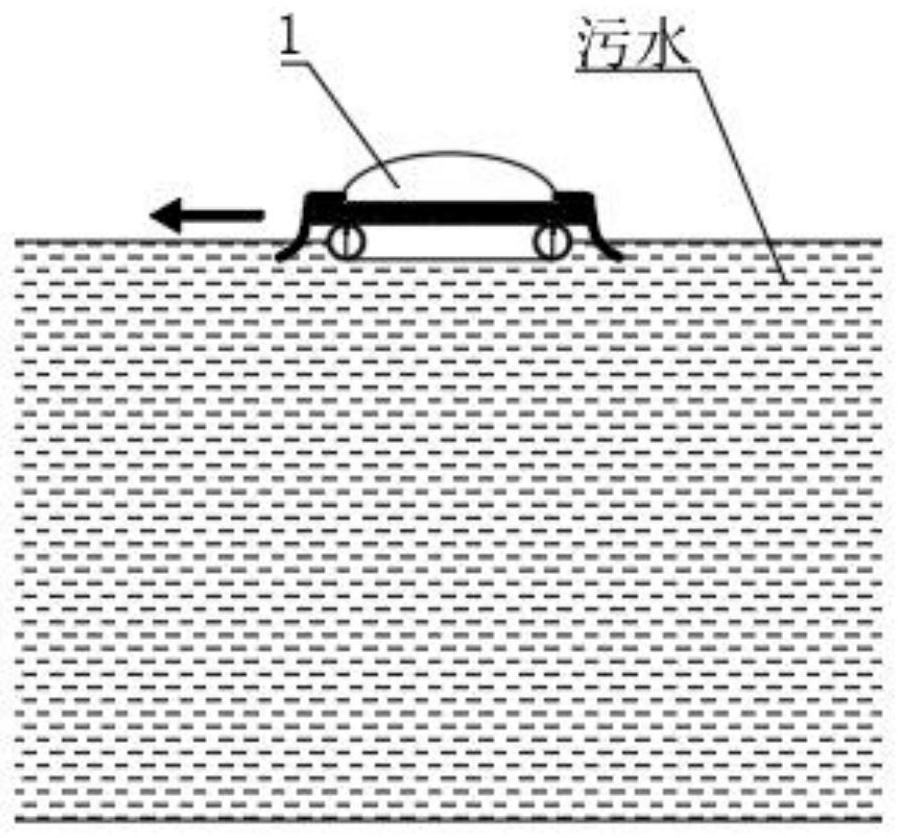

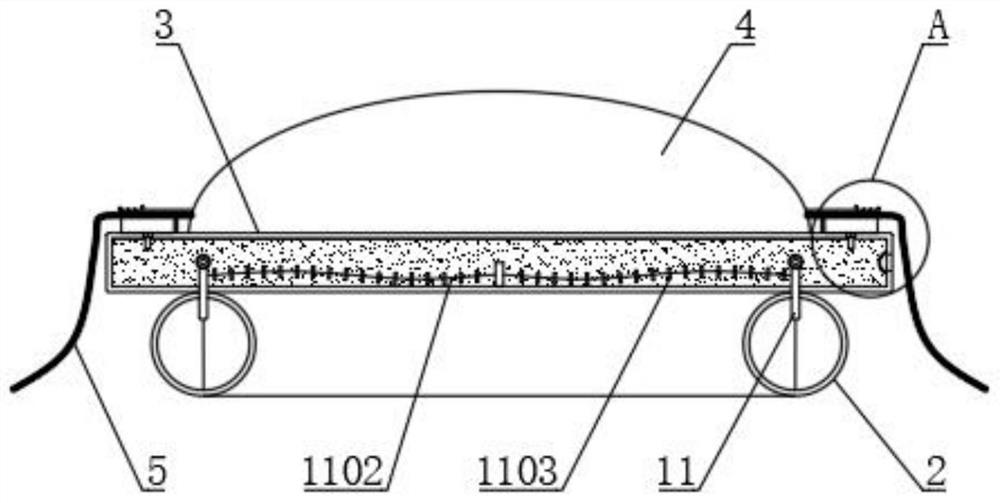

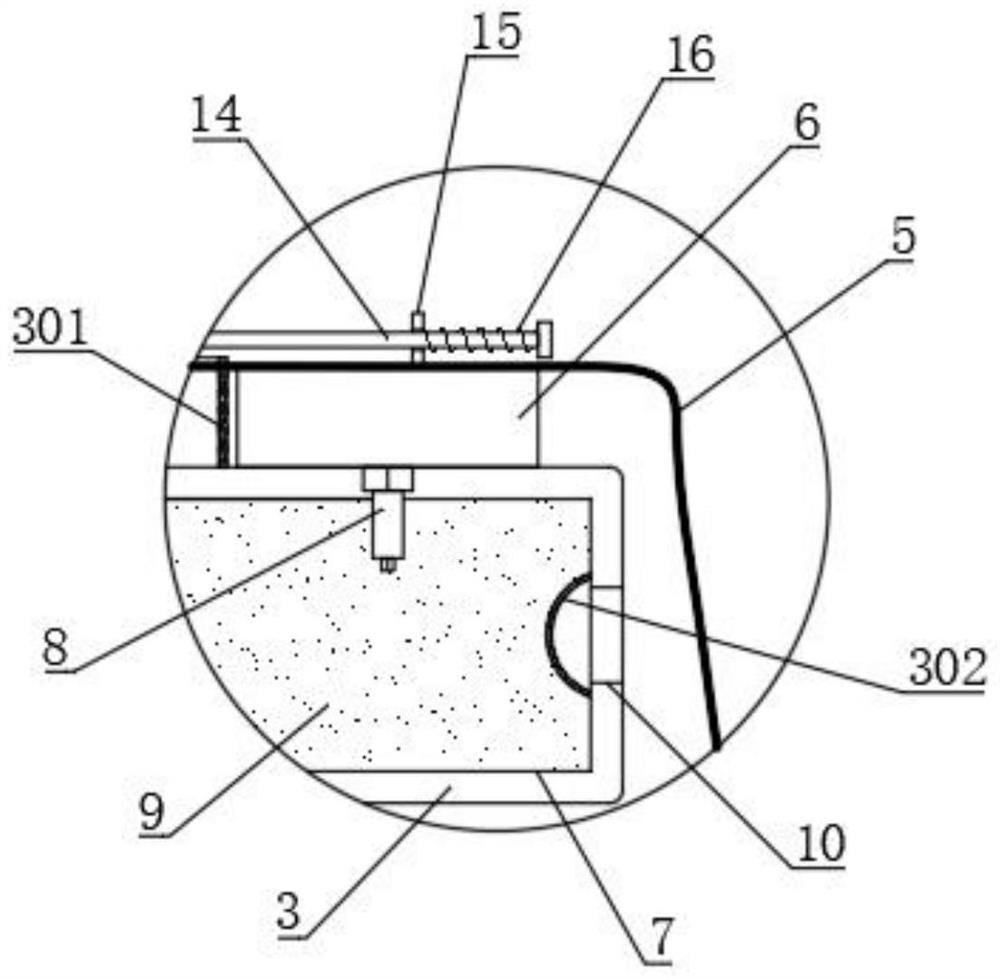

[0042] see Figure 1-3 , a thermal floating type water surface oil pollution adsorption floating plate, comprising an adsorption floating plate 1 floating on the sewage surface, the adsorption floating plate 1 includes a floating bladder tube 2, the upper end of the floating bladder tube 2 is connected with a heat migration disc 3, and the thermal migration disc 3 is connected to the upper end of the floating bladder tube The upper end of the migration disk 3 is connected with an oil-absorbing cotton protrusion 4, and the outer end of the oil-absorbing cotton protrusion 4 is connected with a plurality of evenly distributed oil-absorbing short tentacles 5, and the upper end of the heat transfer disc 3 is connected with an elastic set located outside the oil-absorbing cotton protrusion 4. A water ring 6, a built-in reaction cavity 7 is opened in the heat transfer disk 3, and a plurality of uniformly distributed one-way valves 8 are embedded in the top of the heat transfer disk 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com