A kind of method for preparing insei single crystal

A technology of single crystal and single substance, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of unfavorable InSeI crystal, difficult control of the reaction process, and easy introduction of impurities, so as to achieve good quality, avoid impurity elements from participating in the reaction, The effect of simplifying the reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

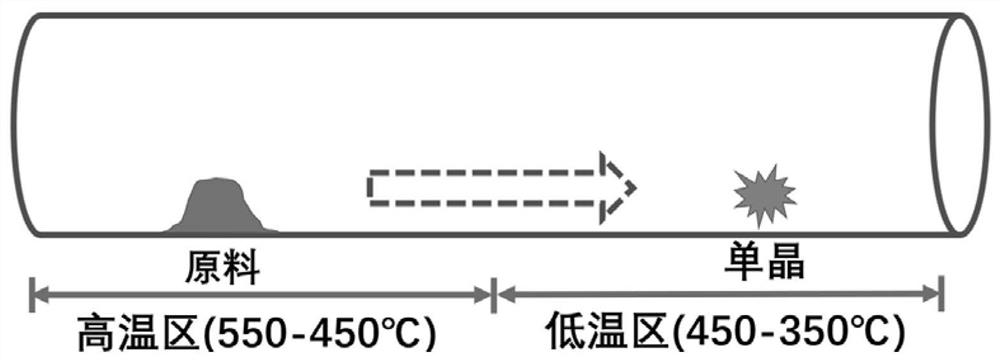

Embodiment 1

[0041] The quartz tube was washed with acetone and deionized water for 0.5 h and dried. The element molar ratio of In, Se, I is 1:1:1.02 In, Se, I 2 The three elements are put into a quartz tube and mixed evenly. Use a vacuum pump to evacuate the air from the quartz tube. And sintered with a mixed flame composed of hydrogen and oxygen to seal it. The quartz tube was then placed horizontally in a dual temperature zone tube furnace for heating. Set the high temperature zone to be heated to 550°C at 1°C / min, and the low temperature zone to be heated to 450°C at 1°C / min. After 8 days of incubation, the temperature is naturally lowered to room temperature, and InSeI crystals can be obtained from the low temperature end.

Embodiment 2

[0043] The quartz tube was washed with acetone and deionized water for 0.5 h and dried. The element molar ratio of In, Se, I is 1:1:1.02 In, Se, I 2The three elements are put into a quartz tube and mixed evenly. Use a vacuum pump to evacuate the air from the quartz tube. And sintered with a mixed flame composed of hydrogen and oxygen to seal it. The quartz tube was then placed horizontally in a dual temperature zone tube furnace for heating. Set the high temperature zone to be heated to 500°C at 1°C / min, and the low temperature zone to be heated to 400°C at 1°C / min. After 10 days of incubation, the temperature is naturally lowered to room temperature, and InSeI crystals can be obtained from the low temperature end.

Embodiment 3

[0045] The quartz tube was washed with acetone and deionized water for 0.5 h and dried. The element molar ratio of In, Se, I is 1:1:1.02 In, Se, I 2 The three elements are put into a quartz tube and mixed evenly. Use a vacuum pump to evacuate the air from the quartz tube. And sintered with a mixed flame composed of hydrogen and oxygen to seal it. The quartz tube was then placed horizontally in a dual temperature zone tube furnace for heating. Set the high temperature zone to be heated to 450°C at 1°C / min, and the low temperature zone to be heated to 350°C at 1°C / min. After 12 days of incubation, the temperature is naturally lowered to room temperature, and InSeI crystals can be obtained from the low temperature end.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com