Method for preparing electret melt-blown cloth material based on zeolite and polypropylene

A polypropylene and melt-blown cloth technology, applied in the direction of single-component polypropylene rayon, melt spinning, rayon manufacturing, etc., can solve the problems of affecting the filtering effect of masks, easy to generate static electricity, and poor impurity adsorption. , to achieve the effect of improving filtration effect, increasing adsorption effect and making high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

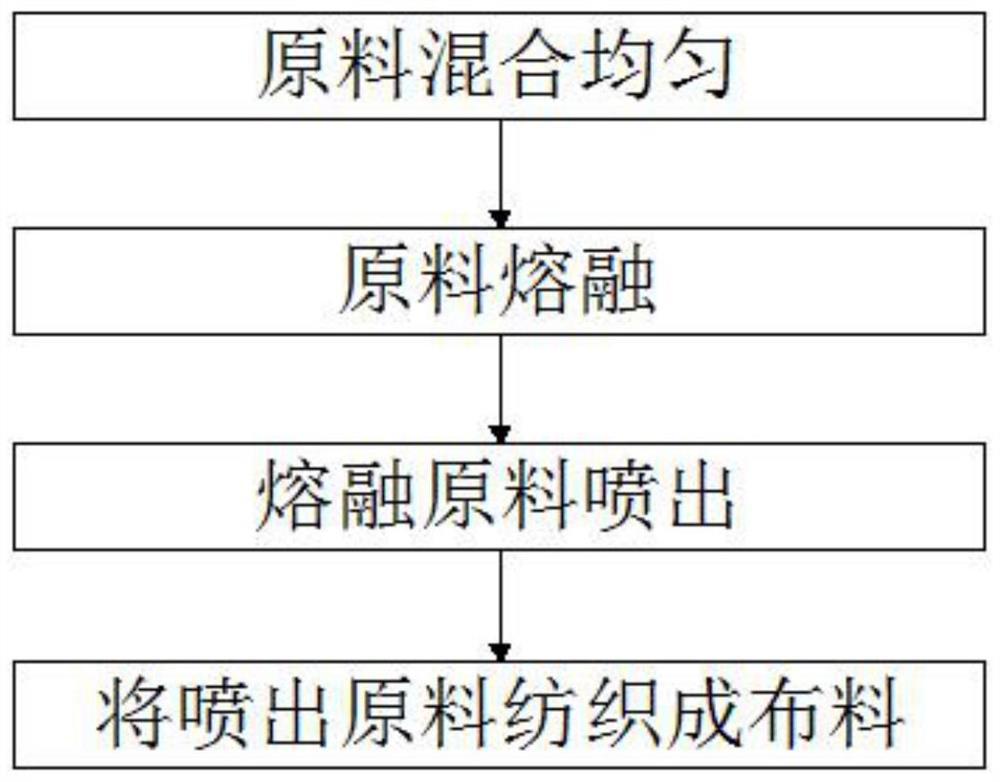

Image

Examples

Embodiment 1

[0038] The specific steps of the method for preparing an electret melt-blown cloth material based on zeolite and polypropylene are as follows:

[0039] S1: The raw materials are evenly mixed: the raw materials of the electret meltblown cloth material are polypropylene, zeolite, and electret masterbatch, and the polypropylene, zeolite, and electret masterbatch are respectively: 80g of polypropylene, 5g of zeolite, and electret Master batch zeolite 5g, stir and mix polypropylene, zeolite and electret master batch evenly to obtain a mixture;

[0040] The particle size of the zeolite is 450-460 mesh;

[0041] S2: Raw material melting: put the mixture uniformly mixed in step S1 in the heating equipment, the heating equipment heats and melts the mixture, the mixture is pressurized during the heating process, and the pressure is 1.5 atmospheres, so that the mixture is heated into a molten material ;

[0042] S3: Molten raw material spraying: put the molten material in step S2 in th...

Embodiment 2

[0045] The specific steps of the method for preparing an electret melt-blown cloth material based on zeolite and polypropylene are as follows:

[0046] S1: The raw materials are mixed evenly: the raw materials of the electret meltblown cloth material are polypropylene, zeolite, and electret masterbatch, and the polypropylene, zeolite, and electret masterbatch are respectively: polypropylene 85g, zeolite 7.5g, electret masterbatch Extreme masterbatch zeolite 7.5g, polypropylene, zeolite, electret masterbatch are stirred and mixed evenly, obtain mixture;

[0047] The particle size of the zeolite is 450-460 mesh;

[0048] S2: Raw material melting: put the mixture uniformly mixed in step S1 in the heating equipment, the heating equipment heats and melts the mixture, the mixture is pressurized during the heating process, and the pressure is 1.5 atmospheres, so that the mixture is heated into a molten material ;

[0049] S3: Molten raw material spraying: put the molten material in...

Embodiment 3

[0052] The specific steps of the method for preparing an electret melt-blown cloth material based on zeolite and polypropylene are as follows:

[0053]S1: The raw materials are mixed evenly: the raw materials of the electret meltblown cloth material are polypropylene, zeolite, and electret masterbatch, and the polypropylene, zeolite, and electret masterbatch are respectively: polypropylene 90g, zeolite 10g, electret Master batch zeolite 10g, stir and mix polypropylene, zeolite and electret master batch evenly to obtain a mixture;

[0054] The particle size of the zeolite is 450-460 mesh;

[0055] S2: Raw material melting: put the mixture uniformly mixed in step S1 in the heating equipment, the heating equipment heats and melts the mixture, the mixture is pressurized during the heating process, and the pressure is 1.5 atmospheres, so that the mixture is heated into a molten material ;

[0056] S3: Molten raw material spraying: put the molten material in step S2 in the extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com