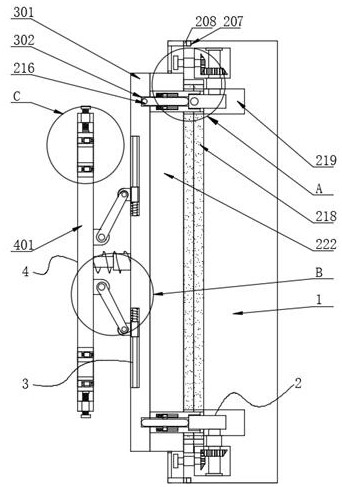

A main building structure with an auxiliary equipment installation bracket

A technology for installing brackets and building main bodies, which is applied to building components, building structures, buildings, etc., can solve the problems of lack of external equipment fixing needs, damage to the overall stress of prefabricated parts, and reduced seismic strength of prefabricated parts, so as to facilitate subsequent maintenance. , Improve installation adaptability, improve installation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

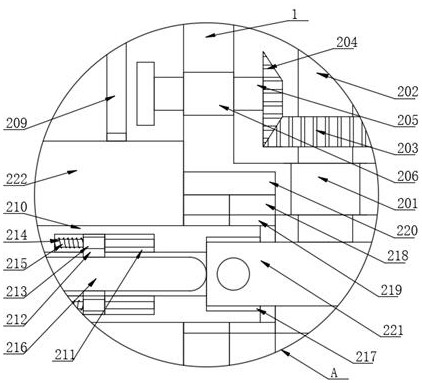

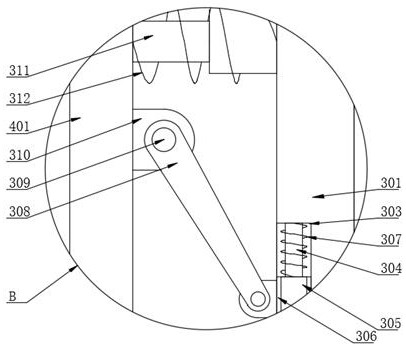

[0046] The specific implementation method is: after the wall body 1 is assembled, the shock absorbing plate 222 is moved into the through hole 219 on one side of the wall body 1, and the second rotating shaft 205 is driven in the second bearing 206 by forwardly turning the handle. Rotate, the protective shell 209 outside the handle can enter the first chute 207 through the first slider 208 on one side, so as to ensure the protective support of the protective shell 209 to the handle, and facilitate pulling and disassembly. The second rotating shaft 205 rotates to drive the driving gear 204 to rotate , the driving gear 204 rotates to drive the driven gear 203 and the first rotating shaft 202 to rotate, and the first rotating shaft 202 rotates to drive the bottom clamping plate 221 to move into the card slot 217 on one side of the card holder 210, and the protrusion on the side of the clamping plate 221 and the clamping groove 217 The inner cavity is pressed and fixed, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com