Ultrafast self-healing polysaccharide-based hydrogel strain sensor and manufacturing method thereof

A strain sensor, hydrogel technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of external stimulation, non-self-healing, poor stretchability, etc., to achieve a wide detection range, widen applications, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: put 7 g soluble potato starch, 1 g polyvinyl alcohol and 0.7 g borax into a beaker;

[0028] Step 2: Add 45 mL of deionized water into the above beaker, and mechanically stir at the oil bath temperature (98 °C) at a speed of 300 r / min for 4 h, so that the starch and polyvinyl alcohol are fully swollen and dissolved, and the borax is completely dissolved to obtain Starch-polyvinyl alcohol-borax sol;

[0029] Step 3: Stop the mechanical stirring and remove the stirring rod, and continue heating in the oil bath at 98 °C for 2 h until the bubbles in the solution are completely removed;

[0030] Step 4: Pour the above sol into the mold and cool at room temperature to obtain a stretchable and ultrafast self-healing polysaccharide conductive hydrogel;

[0031] Step 5: Encapsulate the hydrogel with a stretchable tape and install conductive electrodes to form a flexible strain sensor.

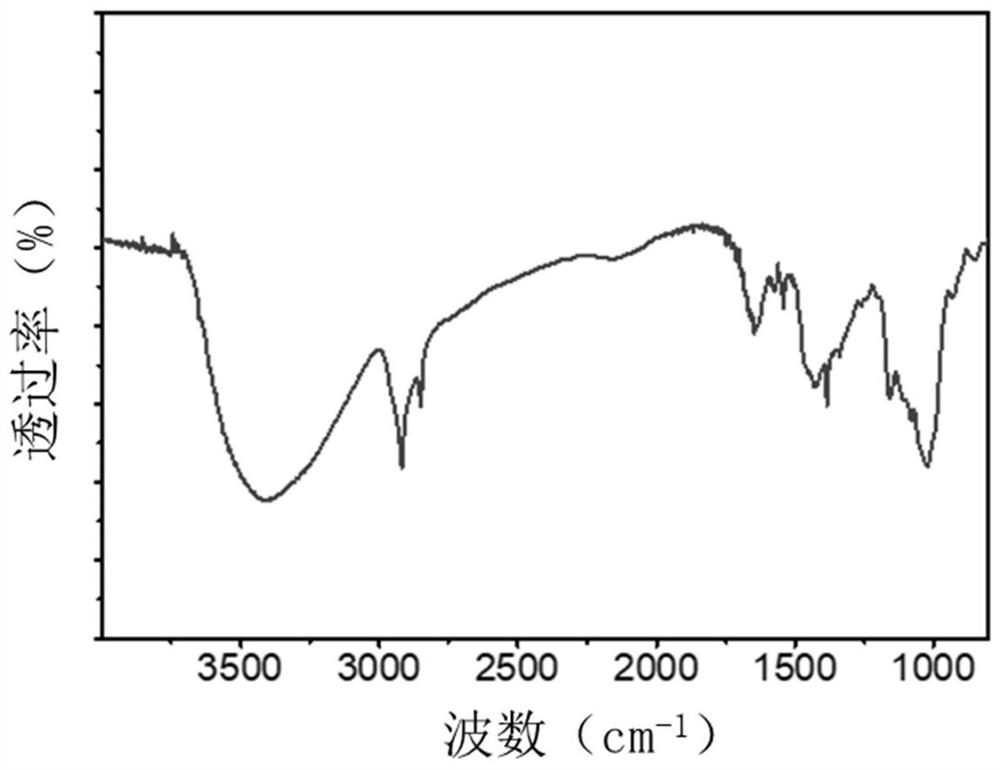

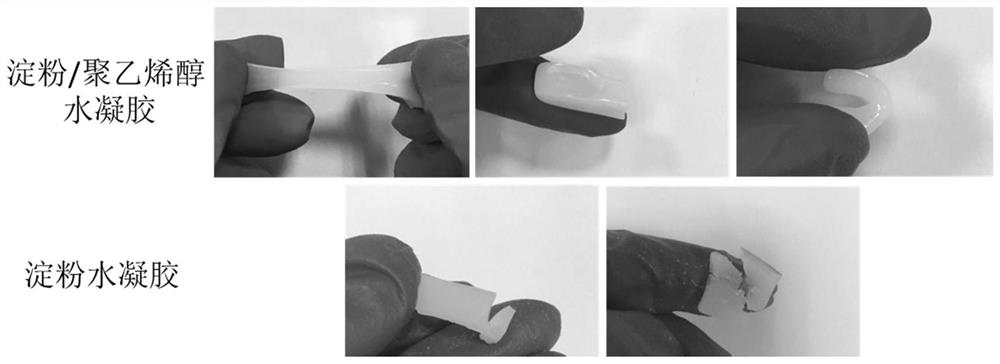

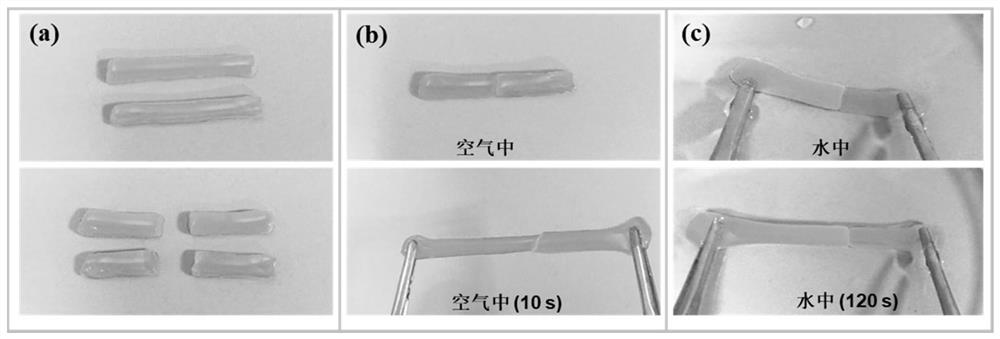

[0032] figure 1 Infrared spectra measured after freeze-drying for the ultrafast se...

Embodiment 2

[0037] Step 1: Put a mixture of 10 g soluble potato starch and carboxymethyl potato starch (2:1), 0.1 g polyvinyl alcohol, and 1 g borax into a beaker;

[0038] Step 2: Add 60 mL of deionized water into the above beaker, and mechanically stir at an oil bath temperature (110 °C) at a speed of 600 r / min for 2 h to fully swell the soluble potato starch-carboxymethyl starch and polyvinyl alcohol Dissolving, borax dissolves completely, obtains soluble potato starch-carboxymethyl starch-polyvinyl alcohol-borax sol;

[0039] Step 3: Stop the mechanical stirring and remove the stirring rod, and continue heating in the oil bath at 110 °C for 2 h until the air bubbles in the sol are completely removed;

[0040] Step 4: Pour the above sol into the mold and cool at room temperature to obtain a stretchable and ultrafast self-healing polysaccharide conductive hydrogel;

[0041] Step 5: Encapsulate the hydrogel with stretchable tape and install conductive electrodes to form a flexible strai...

Embodiment 3

[0044] Step 1: Put 4 g of agarose, 3 g of polyvinyl alcohol, and 0.6 g of borax into a beaker;

[0045] Step 2: Add 70 mL of deionized water into the above beaker, and mechanically stir at the oil bath temperature (100 °C) at a speed of 400 r / min for 3 h, so that the agarose and polyvinyl alcohol are fully swollen and dissolved, and the borax is completely dissolved. Obtain agarose-polyvinyl alcohol-borax sol;

[0046] Step 3: Stop the mechanical stirring and remove the stirring rod, and continue heating in the oil bath at 100 °C for 2 h until the air bubbles in the sol are completely removed;

[0047] Step 4: Pour the above sol into the mold and cool at room temperature to obtain a stretchable and ultrafast self-healing polysaccharide conductive hydrogel;

[0048] Step 5: Encapsulate the hydrogel with stretchable tape and install conductive electrodes to form a flexible strain sensor;

[0049] Referring to Example 1 to investigate the hydrogel-based flexible strain sensor pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com