Blue cover plate glass for photovoltaic building integration and preparation method of blue cover plate glass

A technology for photovoltaic buildings and cover glass, which is used in photovoltaic power generation, sustainable buildings, semiconductor devices, etc., can solve the problems of cumbersome preparation methods, and achieve the effects of high hardness, increased processing resistance, and good processing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

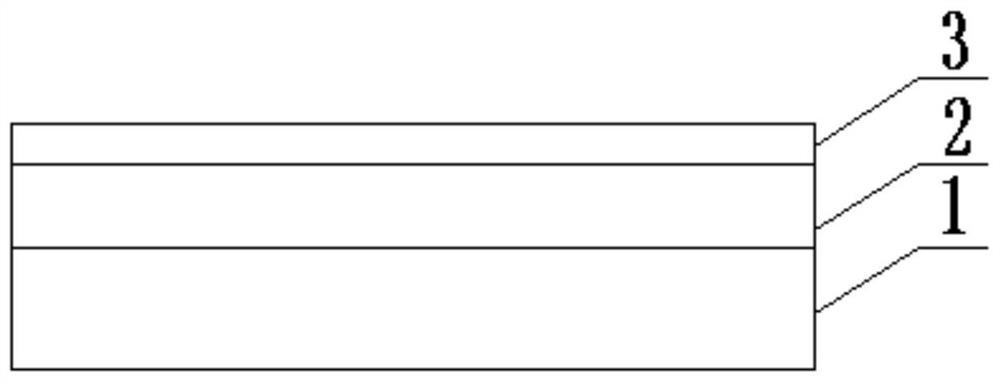

[0029] A blue cover glass for building integration of photovoltaics is composed of a glass substrate, a color layer and a protective layer arranged from bottom to top; the glass substrate is ultra-white glass with a thickness of 6mm, and the color layer is TiO with a thickness of 128nm 2 , the protective layer is ZrO with a thickness of 5 nm 2 .

[0030] The preparation method is:

[0031] (1) Clean the glass substrate with ultrapure water, and set the line speed to 2.0m / min;

[0032] (2) Transfer the glass substrate into the coating chamber after pre-vacuum transition, and the background vacuum of the coating chamber is less than 1×10 - 5 mbar, magnetron sputtering coating equipment installs incompletely oxidized TiO x Target, the purity of argon gas is greater than 99.99%, the flow rate is 800sccm, the purity of oxygen gas is greater than 99.99%, the flow rate is 20sccm, and the working pressure is 2~5×10 -3 mbar, set the total power of the target to 480KW, and use the ...

Embodiment 2

[0035] A blue cover glass for building integration of photovoltaics is composed of a glass substrate, a color layer and a protective layer arranged from bottom to top; the glass substrate is ultra-white patterned glass with a thickness of 6mm, and the color layer is ZnSnO with a thickness of 145nm 2 , the protective layer is ZrO with a thickness of 8 nm 2 .

[0036] The preparation method is:

[0037] (1) Clean the glass substrate with ultrapure water, and set the line speed to 2.0m / min;

[0038] (2) Transfer the glass substrate into the coating chamber after pre-vacuum transition, and the background vacuum of the coating chamber is less than 1×10 - 5 mbar, magnetron sputtering coating equipment is installed with ZnSn target, Zn / Sn is 1:1, the purity of argon gas is greater than 99.99%, the flow rate is 400sccm, the purity of oxygen gas is greater than 99.99%, the flow rate is 800sccm, and the working pressure is 2~5×10 -3 mbar, set the total power of the target to 350KW, ...

Embodiment 3

[0041] A blue cover glass for photovoltaic building integration, which is composed of a glass substrate, a color layer and a protective layer arranged from bottom to top; the glass substrate is ultra-white glass with a thickness of 6mm, and the color layer is Nb with a thickness of 132nm. 2 O 5 , the protective layer is SiZrO with a thickness of 7 nm 2 .

[0042] The preparation method is:

[0043] (1) Clean the glass substrate with ultrapure water, and set the line speed to 2.0m / min;

[0044](2) Transfer the glass substrate into the coating chamber after pre-vacuum transition, and the background vacuum of the coating chamber is less than 1×10 - 5 mbar, magnetron sputtering coating equipment installs incompletely oxidized NbO x Target, the purity of argon gas is greater than 99.99%, the flow rate is 800sccm, the purity of oxygen gas is greater than 99.99%, the flow rate is 200sccm, and the working pressure is 2~5×10 -3 mbar, set the total power of the target to 350KW, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com