Puncture-proof and cut-proof white gown and manufacturing method thereof

A white coat and cut-resistant technology, applied in protective clothing, clothing, clothing, etc., can solve the problems of affecting the wearing experience, poor moisture permeability, thick thickness, etc., and achieve the effect of light weight, good stretch elasticity, and fashionable style.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

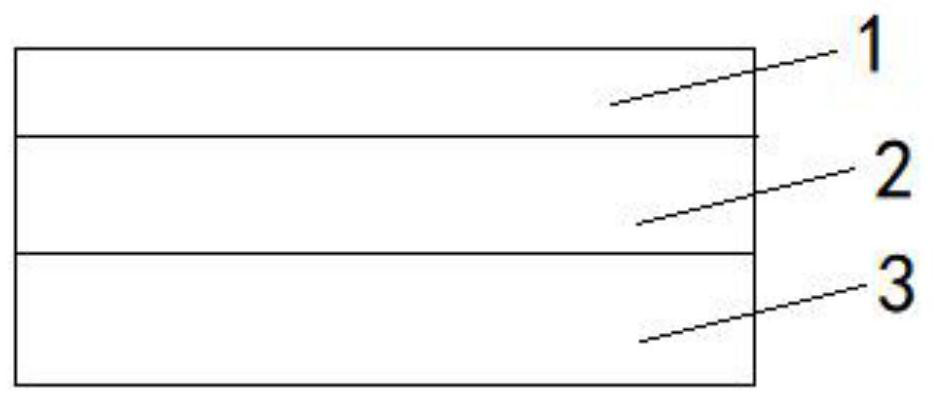

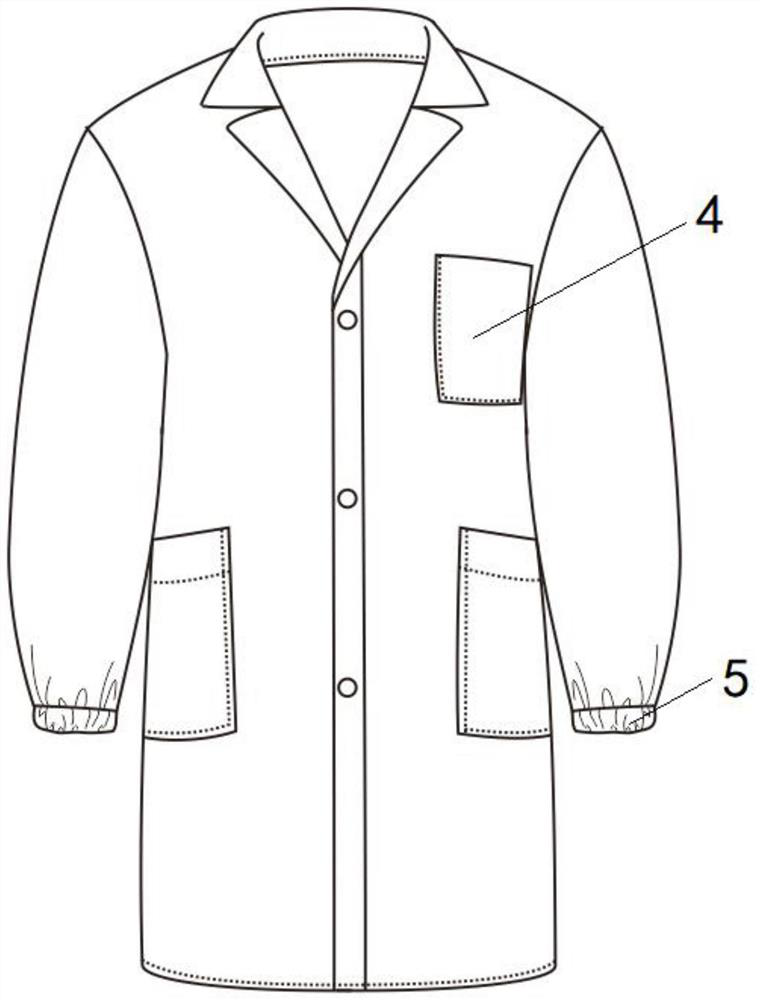

[0032] Such as figure 1 with figure 2 As shown, the present invention provides a puncture-resistant and cut-resistant white coat, which includes a first layer of surface fabric 1 and a second layer of cut-resistant puncture fabric 2 that are integrally stitched and connected.

[0033] As a preferred embodiment, the first layer of surface fabric 1 is made of one or more composite weaves of cotton, polyester, nylon, spandex, vinylon, wool, animal fiber, modal, bamboo fiber, and conductive yarn. 32-count combed polyester-cotton woven fabric is preferred, and it is bleached white fabric, with a grammage of 160g / m 2 , the thickness is 0.2mm.

[0034] As a preferred embodiment, the second layer of cut-resistant puncture fabric 2 is made of one or more of aramid fibers, high-strength high-modulus polyethylene fibers, high-strength polyester fibers, high-strength nylon fibers, glass fibers, basalt fibers, and metal fibers. Weaving, preferably high-strength and high-modulus polyeth...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that it also includes a third layer of inner layer fabric 3, the first layer of surface layer fabric 1, the second layer of anti-cut puncture fabric 2 and the third layer of inner layer fabric 3 are integrated sequentially Seamed connection.

[0049] The preparation method of the above-mentioned stab-proof and cut-proof white coat is as follows:

[0050] S1. The second layer of anti-cut and puncture fabric 2 and the third layer of inner layer fabric 3 are sewn together to form a whole after the front chest, back and sleeves of the white coat are seamed together, and then stitched and pressed on the first layer of surface fabric 1. The reason for adopting this kind of stitching method is that the second layer of cut-resistant fabric 2 has a certain thickness, and the chest and back are stitched together in 6 layers. The stitching position is too thick, and it is difficult for machine sewing equipment to sew. The...

Embodiment 3

[0055] Such as figure 1 with figure 2 As shown, the present invention provides a puncture-resistant and cut-resistant white coat, which includes a first layer of surface fabric 1 and a second layer of cut-resistant puncture fabric 2 that are integrally stitched and connected.

[0056] As a preferred embodiment, the first layer of surface fabric 1 is made of one or more composite weaves of cotton, polyester, nylon, spandex, vinylon, wool, animal fiber, modal, bamboo fiber, and conductive yarn. 72-count double-ply combed pure cotton woven fabric is preferred, and it is bleached white fabric, with a grammage of 175g / m 2 , the thickness is 0.25mm.

[0057] As a preferred embodiment, the second layer of cut-resistant puncture fabric 2 is made of one or more of aramid fibers, high-strength high-modulus polyethylene fibers, high-strength polyester fibers, high-strength nylon fibers, glass fibers, basalt fibers, and metal fibers. Weaving, preferably high-strength and high-modulus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com