Robot system for egg food processing

A robot system and food processing technology, applied in the field of robot systems for egg food processing, can solve the problems of reducing the economic benefits and use value of egg food processing equipment, and the inability to accurately control water volume, water temperature, manpower and energy waste, etc., to achieve Significant economic benefits and use value, complete structure, and the effect of solving human and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

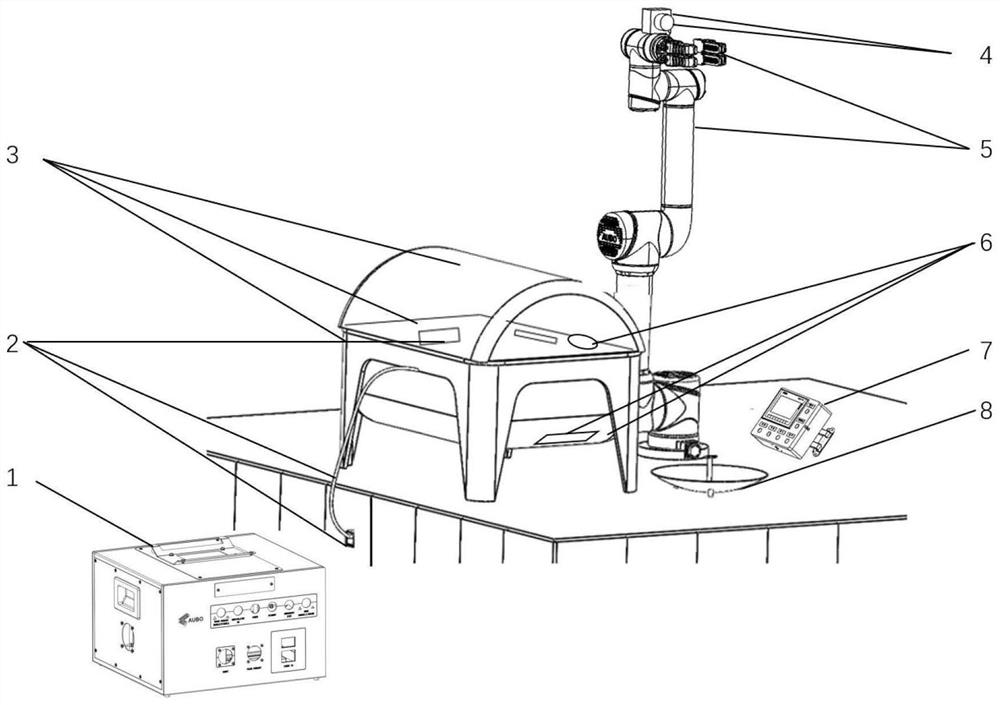

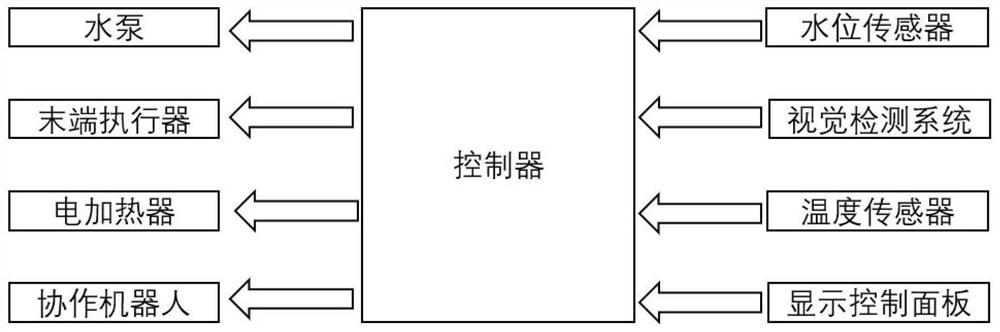

[0022] The invention provides a robot system for egg food processing, which is characterized by comprising a controller 1, an automatic water supply system 2, cooking equipment 3, a visual detection system 4, a collaborative robot 5, an adjustable temperature control system 6, and a display control panel 7 , Movable egg placement mechanism 8, steaming equipment 3, movable egg placement mechanism 8, collaborative robot 5, display control panel 7 are respectively arranged on the desktop; mobile egg placement mechanism, collaborative robot 5, display control panel 7 respectively It is arranged on the right side of the cooking equipment 3; the mobile egg placement mechanism is connected with the collaborative robot 5; the display control panel 7 is respectively arranged on the right side of the mobile egg placement mechanism and the collaborative robot 5; the upper end of the collaborative robot 5 is connected with a visual inspection system 4. One end of the automatic water supply...

Embodiment 2

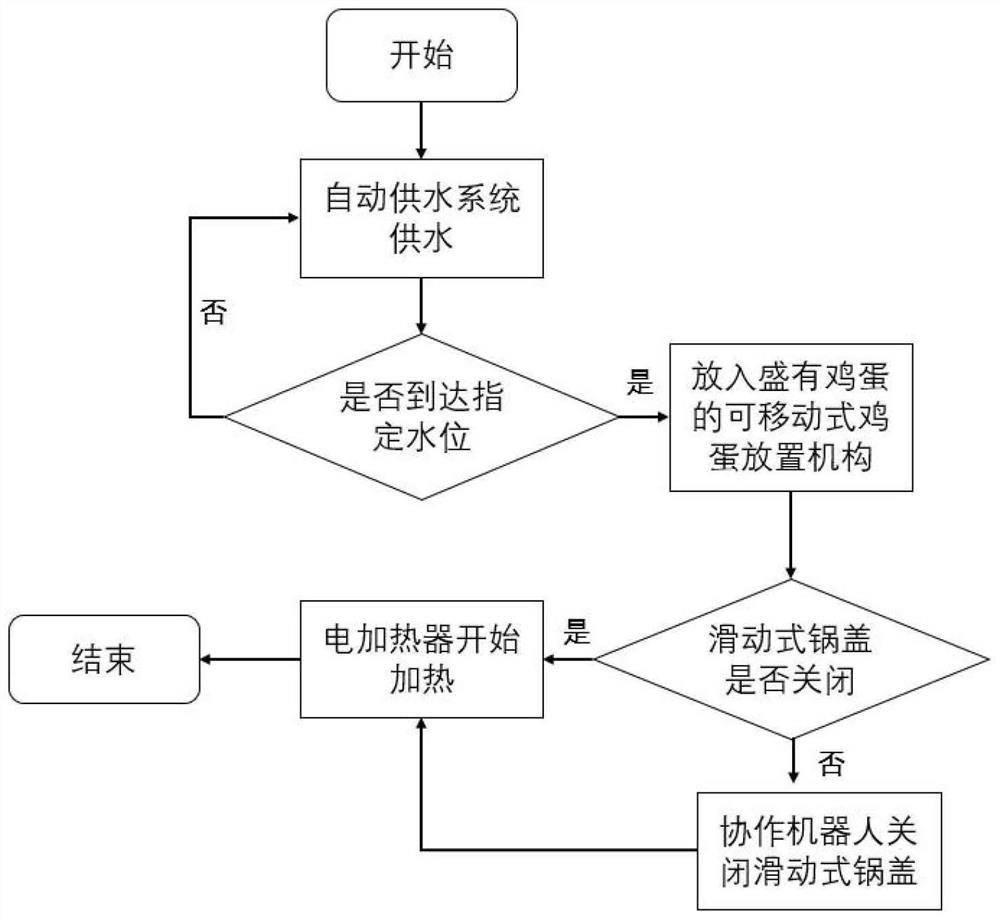

[0030] A robotic system for egg food processing such as figure 1 As shown, it mainly includes automatic water supply system 2, cooking equipment 3, visual inspection system 4, collaborative robot 5, adjustable temperature control system 6, display control panel 7, movable egg placement mechanism 8; adjustable temperature control system 6 is installed on the cooking equipment 3, according to figure 2As shown, in the process of automatic egg food processing, the automatic water supply system 2 completes the automatic water addition of the egg cooking tank 5-9 through the controller 1 and the water level sensor 5-3. When setting the safe water level, trigger the water level sensor 5-3 to send a signal to the controller 1, and the controller 1 sends an instruction to the water pump 5-1, and the water pump 5-1 starts to supply water to the egg cooking tank 5-9 until the predetermined water level is adjustable. After the automatic water supply system 2 enters the designated water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com