A Constraint Release Type Differential Piezoelectric Ultrasonic Transducer Chip and Its Working Method

A piezoelectric ultrasonic and transducer technology, which is applied in the direction of sound-generating equipment, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of increasing the vibration amplitude of the transducer, increasing the output of useful signals, and increasing the sensitivity of the transducer and other problems, to achieve the effect of increasing the vibration amplitude, increasing the useful signal output, and reducing the residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

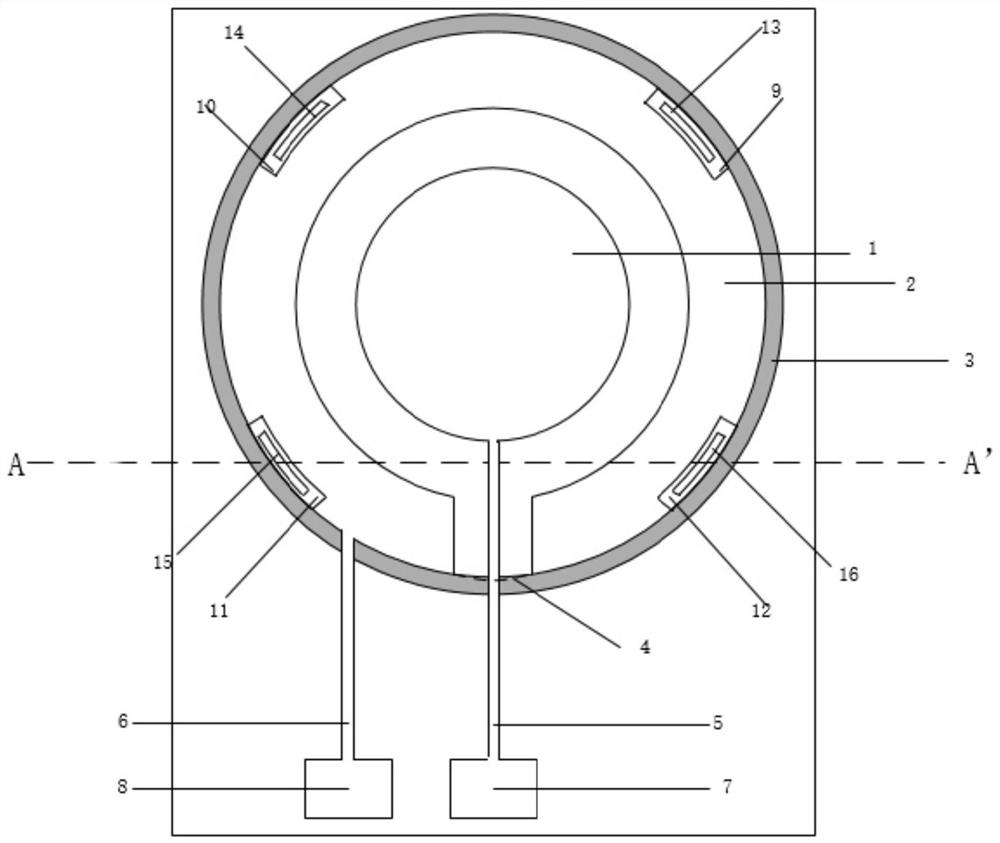

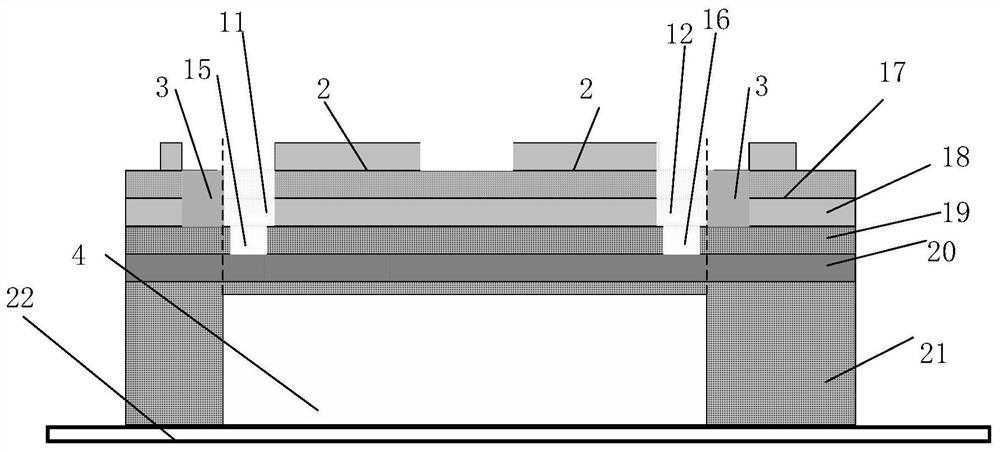

[0032] Such as figure 1 and figure 2 As shown, this embodiment discloses a constraint-releasing differential piezoelectric ultrasonic transducer chip, which includes a support layer, a bottom electrode 18 , a piezoelectric layer 17 and a top electrode in order from bottom to top. The support layer includes a base layer 21 , a stop layer 20 and an elastic layer 19 from bottom to top, and a cavity 4 is provided in the middle of the bottom of the base layer 21 corresponding to the central area of the entire ultrasonic transducer chip. In this embodiment, the base layer 21 is disposed on the fixing plate 22 , the cavity 4 runs through the base layer 21 , and the cavity 4 is a circular cavity 4 .

[0033] The top electrode includes a top internal electrode 1 and a top external electrode 2 surrounding the top internal electrode 1. The top internal electrode 1 is connected to the top internal electrode lead-out interface 7 through the top internal electrode lead-out line 5, and t...

Embodiment 2

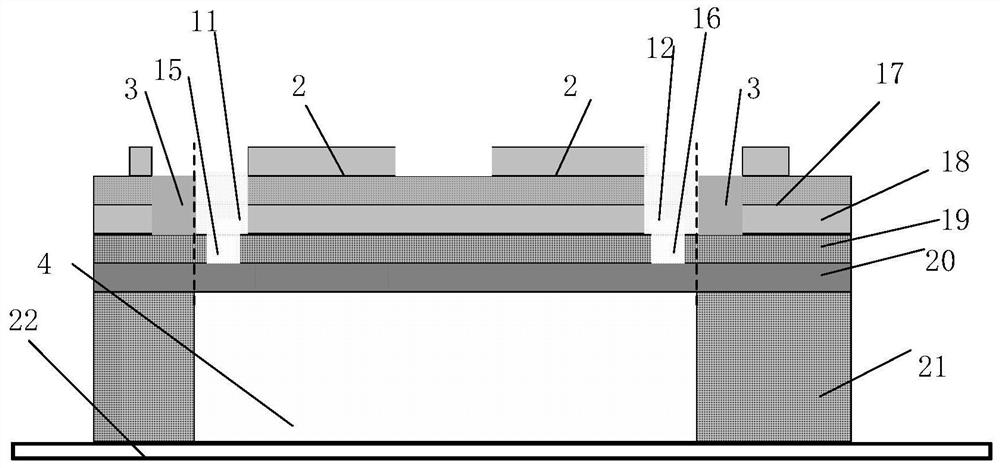

[0044] The difference between this embodiment and Embodiment 1 is that, if image 3 As shown, in this embodiment, the cavity 4 does not penetrate the base layer 21, that is, a layer of film support layer is formed on the top of the base layer 21. This method can improve the yield, and also improve the resistance of the device, and enhance the damage of the chip to the outside world. survivability under the action.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that, if Figure 4 and Figure 5 As shown, in this embodiment, the mechanical slot group is arranged between the top inner electrode 1 and the top outer electrode 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com