Intelligent filling method and system

A filling system and intelligent technology, which is applied in packaging, transportation and packaging, and packaging item types, etc., can solve problems such as unstable measurement accuracy, difficulty in controlling cross-contamination of liquid medicine, and pollution in production areas, so as to reduce human labor Strength and production costs, increase the probability of filling abnormalities, and the effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

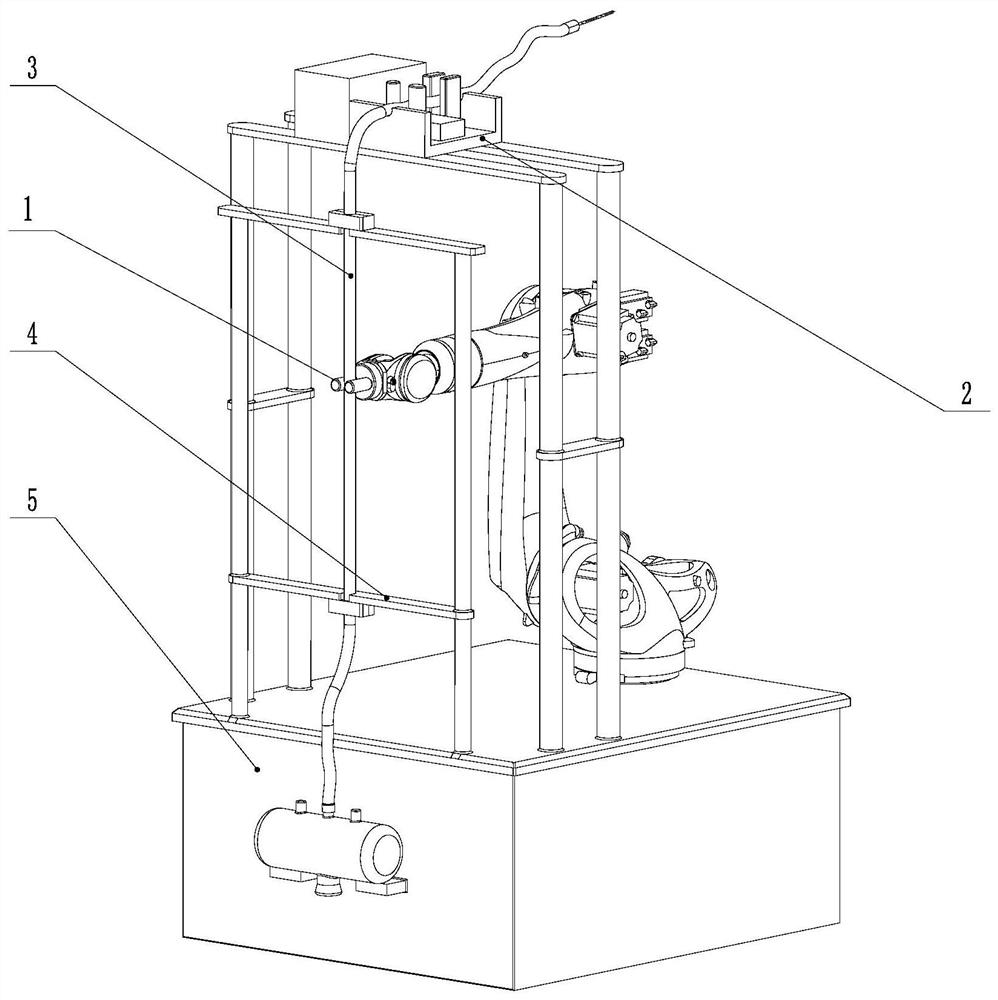

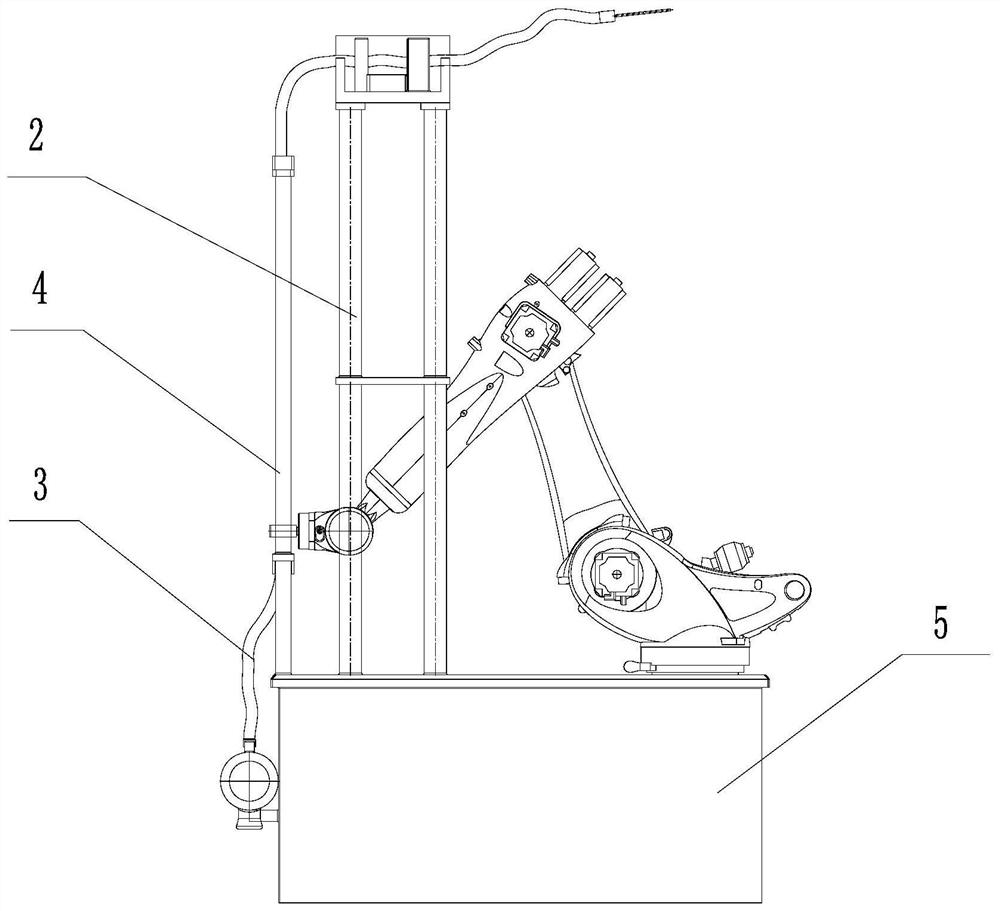

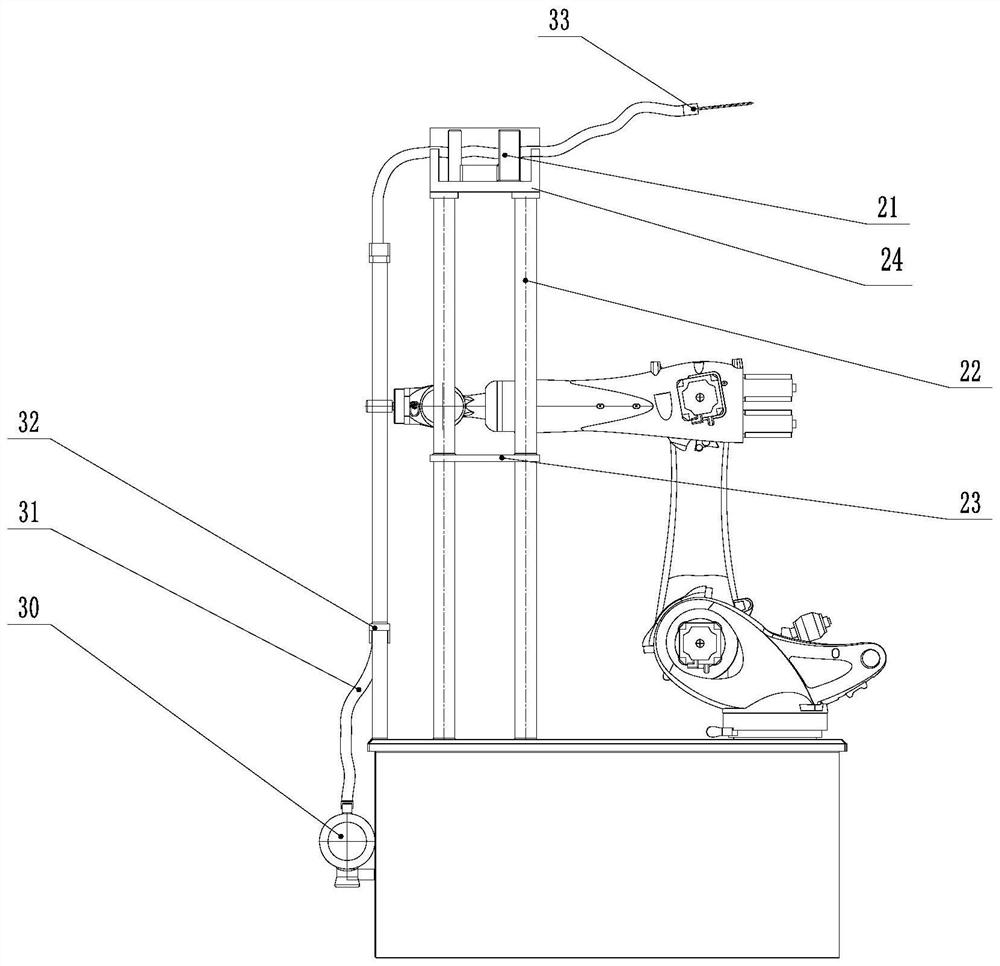

[0040] Such as Figure 1 to Figure 4 As shown, the intelligent filling system for implementing the above-mentioned intelligent filling method of the present invention includes: an intelligent manipulator, an anti-backflow assembly 2, a pipeline assembly 3, a pipe rack assembly 4 and a rack assembly 5; an intelligent manipulator, an anti-backflow Assembly 2 and pipe frame assembly 4 are both installed on frame assembly 5; one end of pipeline assembly 3 is installed on pipe frame assembly 4, and the other end of pipeline assembly 3 is installed on frame assembly 5; anti-backflow assembly 2 is located on At one end of the pipeline assembly 3, the anti-backflow assembly 2 is used to clamp and loosen the pipeline assembly 3; when filling, the pipeline assembly 3 is squeezed by the intelligent manipulator to achieve metering delivery; the intelligent manipulator is connected to the control panel, and through the control panel Set the motion parameters of the smart manipulator.

[0...

Embodiment 2

[0051] Such as Figure 5 to Figure 7 As shown, the intelligent filling system for implementing the above-mentioned intelligent filling method of the present invention has roughly the same structure and working principle as the intelligent filling system in Embodiment 1, the difference is that the intelligent manipulator is a two-axis manipulator; The gripper of the intelligent manipulator is a single roller 6, and the pipeline assembly 3 is squeezed by the single roller 6. Correspondingly, a baffle 7 is also provided between the lower limiter 42 and the upper limiter 43 , and the baffle 7 is used to assist the single-roller intelligent manipulator to squeeze the elastic hose 31 to realize metered delivery of the fluid.

[0052] It should be noted that, if Figure 6 and Figure 7 As shown, in this embodiment, the setting position of the baffle plate 7 between the lower limiter 42 and the upper limiter 43 corresponds to the hose joint 32, and the main purpose is to make the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com