Oilfield chemical scale inhibitor, preparation method and application thereof

An anti-scaling agent and chemical technology, applied in the direction of chemical instruments and methods, descaling and water softening, special treatment goals, etc., can solve the problem of narrow adaptability range of temperature and PH value, low anti-scaling efficiency of anti-scaling agent, and difficult to meet the on-site requirements Demand and other issues, to achieve the effect of small environmental impact, good temperature resistance, excellent anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

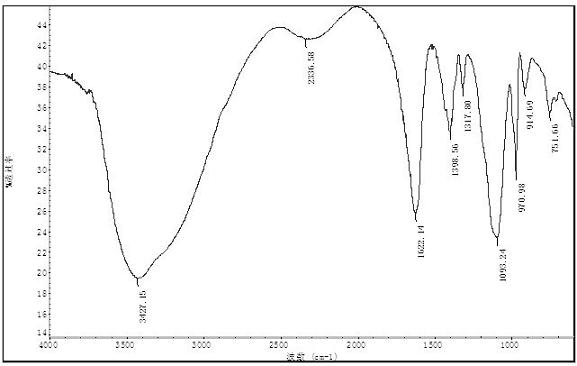

Image

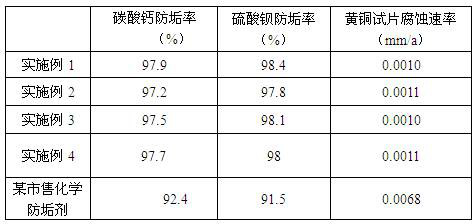

Examples

Embodiment 1

[0042]This embodiment provides an oilfield chemical antiscaling agent, comprising the following parts by weight: 75 parts of nitrogen-containing organic polyphosphonic acid, 15 parts of sodium polyepoxysuccinate, 5 parts of chelating dispersant, and 5 parts of water.

[0043] The preparation process of oilfield chemical antiscaling agent:

[0044] Under normal temperature and pressure, add the water of formula quantity in reaction kettle, then add the chelating dispersant of formula quantity, after stirring and dissolving, add the sodium polyepoxysuccinate of formula quantity and nitrogen-containing organic polyphosphonic acid successively, stir until Dissolve completely, that is.

[0045] Among them, the nitrogen-containing organic polyphosphonic acid is a mixture of tetrasodium aminotrimethylene phosphonate and sodium ethylenediamine tetramethylene phosphonate, and the mass ratio of the two is (6.3-6.7): (0.8-1.2).

[0046] Nitrogen-containing organic polyphosphonic acid ad...

Embodiment 2

[0054] This example provides an oilfield chemical antiscaling agent, comprising 70 parts of nitrogen-containing organic polyphosphonic acid, 14 parts of sodium polyepoxysuccinate, 3 parts of chelating dispersant, and 3 parts of water.

[0055] The preparation process of oilfield chemical antiscaling agent:

[0056] Under normal temperature and pressure, add the water of formula quantity in reaction kettle, then add the chelating dispersant of formula quantity, after stirring and dissolving, add the sodium polyepoxysuccinate of formula quantity and nitrogen-containing organic polyphosphonic acid successively, stir until Dissolve completely, that is.

[0057] Wherein, the nitrogen-containing organic polyphosphonic acid is a mixture of tetrasodium aminotrimethylene phosphonate and sodium ethylenediamine tetramethylene phosphonate, and the mass ratio of the two is 6.3:1.2. The solid content of sodium polyepoxysuccinate was 35.52wt%. The chelating dispersant is a maleic acid-acry...

Embodiment 3

[0061] This embodiment provides an oilfield chemical antiscaling agent, which includes the following raw materials in parts by weight: 80 parts of nitrogen-containing organic polyphosphonic acid, 16 parts of sodium polyepoxysuccinate, 7 parts of chelating dispersant, and 7 parts of water.

[0062] The preparation process of oilfield chemical antiscaling agent:

[0063] Under normal temperature and pressure, add the water of formula quantity in reaction kettle, then add the chelating dispersant of formula quantity, after stirring and dissolving, add the sodium polyepoxysuccinate of formula quantity and nitrogen-containing organic polyphosphonic acid successively, stir until Dissolve completely, that is.

[0064] In this embodiment, the nitrogen-containing organic polyphosphonic acid is a mixture of tetrasodium aminotrimethylene phosphonate and sodium ethylenediamine tetramethylene phosphonate, and the mass ratio of the two is 6.7:0.8. The solid content of sodium polyepoxysucci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap