Biogas digester reloading device suitable for reloading of low-temperature biogas digesters

A biogas digester and low temperature technology, which is applied in the field of biogas digester refueling equipment, can solve the problems of manual slag removal, reduced fermentation space, hidden dangers, etc., and achieves the effects of improving utilization, increasing initial temperature, and eliminating hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

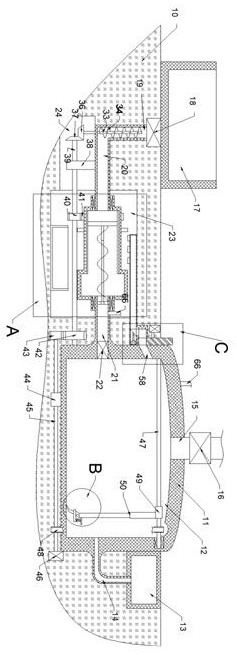

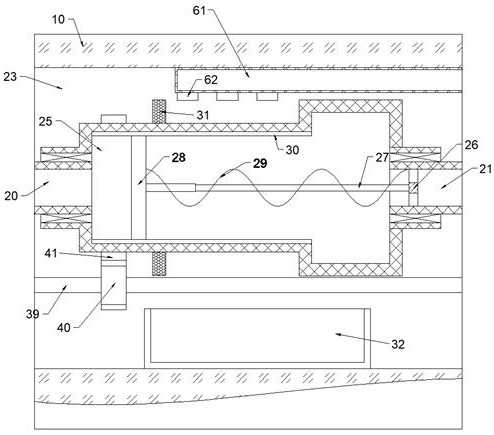

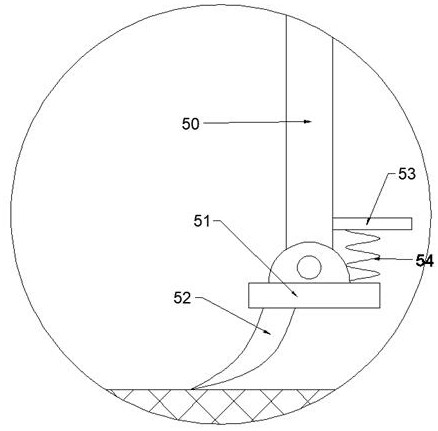

[0022] By below Figure 1-5 The present invention will be described in detail, in which it is convenient, and now, the orientation of the following statement is as follows: The above-mentioned left and right directions and figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0023] Suitable for use in conjunction with the accompanying biogas digester 1-5 cryogenic refueling refueling apparatus 10 comprises a foundation, the foundation 10 is provided in the heating chamber 23, the gear chamber 24, is provided in the foundation 10 there digester 11, the digester 11 is provided with the fermentation chamber 12, the upper end of the foundation 10 is provided with fixing grooves 17 raw material, the raw material tank 17 communicates with the lower end of the feed valve 18, the lower end of the feed discharge valve 18 communication with feed chamber 19, the lower end of the feed chamber 19 communicates with the communication chamber 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com