Abutment method for carbon dioxide incubator and isolator

A technology of carbon dioxide and isolators, applied in biochemical equipment and methods, sterilization methods, methods of supporting/immobilizing microorganisms, etc., can solve the problem of poor temperature uniformity in the box, poor connection reliability with the isolator, and low space utilization and other problems, to achieve the effect of eliminating pollution, avoiding condensation, and facilitating automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

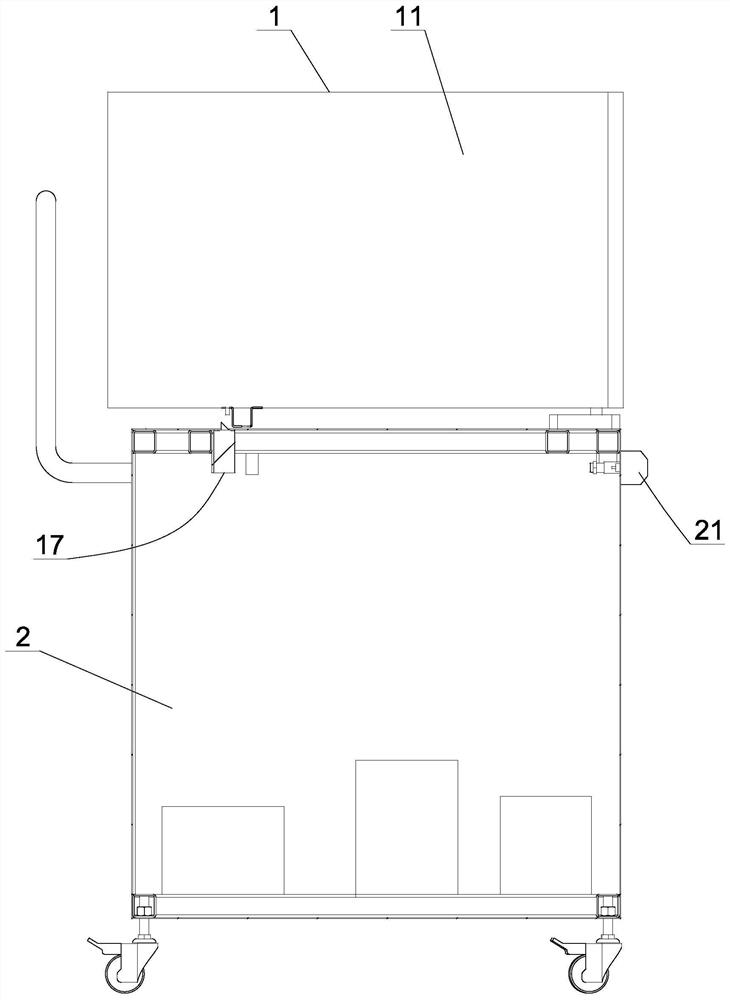

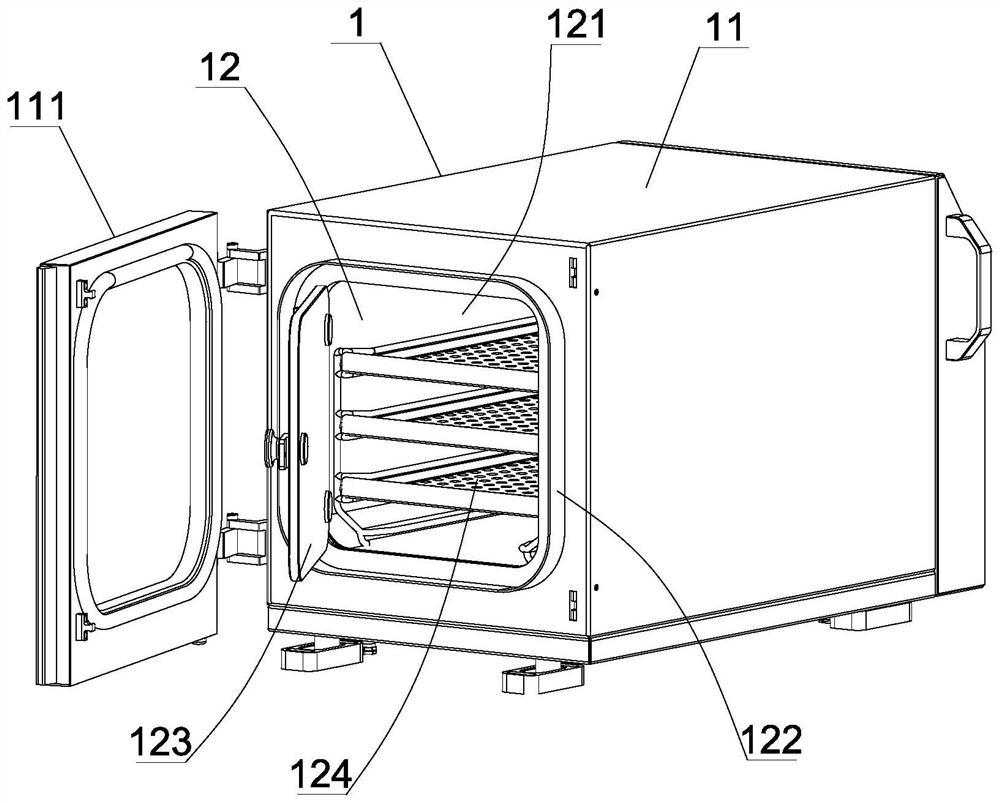

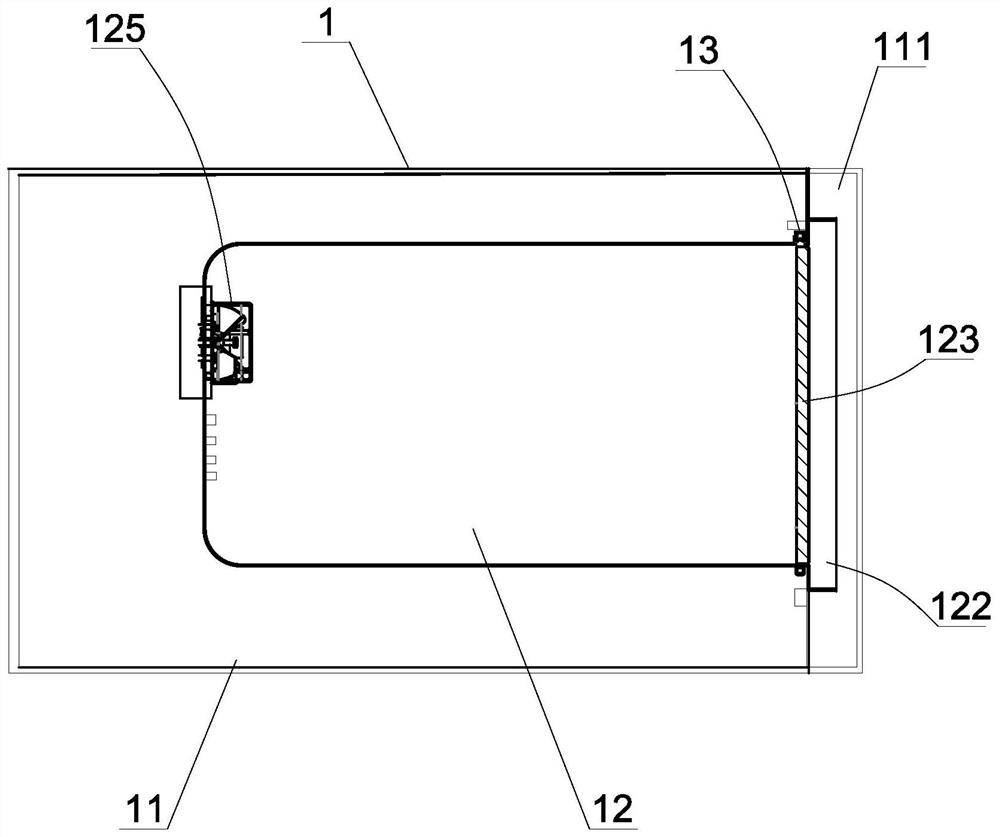

[0057] Such as figure 1 , figure 2 , image 3As shown, a carbon dioxide incubator and a docking method with an isolator, wherein the isolator is provided with a glove opening that seals the inside and outside of the isolator, and the incubator 1 includes an outer body that is movably arranged on a mobile vehicle 2 Case 11 and inner case 12 located in the outer case, so that the incubator forms a double-layer structure. For ease of description, in this embodiment, when the incubator moves on the mobile vehicle, the side close to the isolator is called the front side, and the side away from the isolator is called the rear side. Outer box is provided with the outer box door 111 that can rotate outwards and opens at the front side of moving direction, and the electric heating element that makes inner box keep cultivating temperature is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com