Solid filling gob-side entry retaining process system and construction method

A technology of solid filling and filling body, which is applied in the direction of filling, earthwork drilling, safety devices, etc., which can solve the problems of low efficiency and difficulty of filling and retaining roads, and achieve cost saving, labor workload reduction, and economical and applicable effects good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

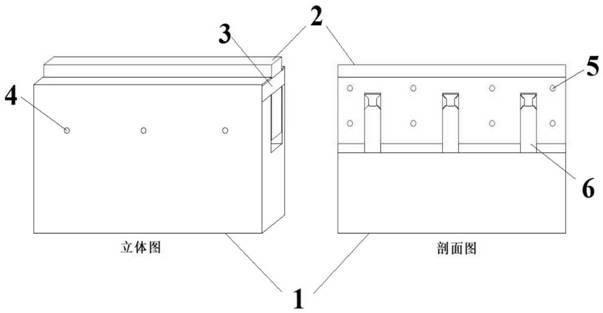

[0024] see figure 1 , a retractable high-strength gangue board, mainly composed of base wall 1, expansion board 2 and built-in jack 6 and other three parts. The base wall 1 is in the lower part, which mainly plays the role of foundation support and bedding, and the expansion plate 2 is in the upper part, which mainly plays the role of connecting the roof and preventing the overflow of the filling material in the upper part of the base wall 1 . The upper part of the base wall 1 is made into a U-shaped groove, and a stopper 3 is welded on both sides of the U-shaped groove to limit the left and right displacement of the telescopic plate 2. 3-4 jacks 6 are fixed in the groove of the base wall 1, and the liquid injection holes 4 of the jack 6 are drilled outside the groove of the base wall 1 according to the positions of the jacks 6 . Expansion plate 2 is made a plurality of U-shaped grooves according to jack 6 quantity, and whole expansion plate 2 is similar to m shape, and jack ...

Embodiment 2

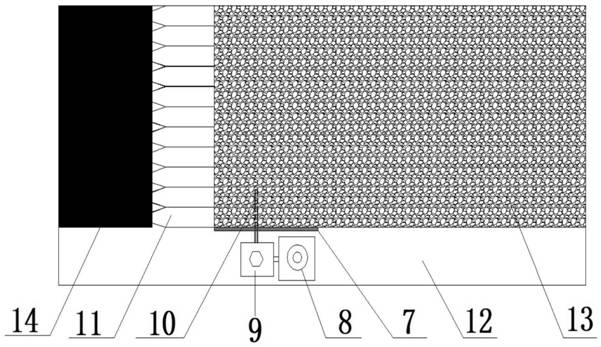

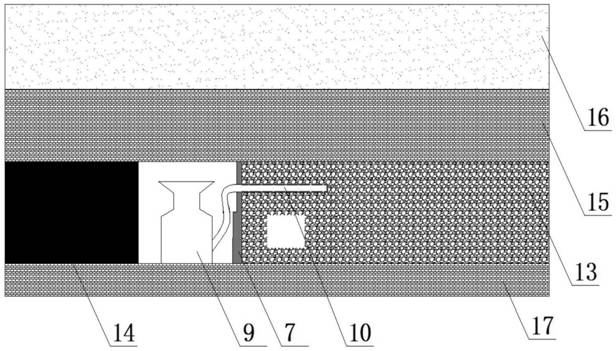

[0026]When solid filling is carried out along the entry retaining, first fix the gangue board 7 on the edge of the goaf on the side of the entry retention, inject liquid into the built-in jack 6, and stretch the telescopic plate 2, so that the gangue board 7 can be densely connected to the top and bottom , to prevent material spillage while being able to resist the lateral pressure exerted by the filling material. After the leakage-tamping filling operation starts, start the mixer 8 in the entry retention, and mix the grouting materials prepared in advance according to a certain ratio, and the filling materials should have certain fluidity, pumpability and timeliness. When the gangue leakage-tamping filling operation is carried out to the middle of the working face, the high-strength grouting pipeline 10 is inserted into the filling body from the grouting hole 5 of the gangue plate, and the insertion length is generally more than 90% of the width of the reserved roadside body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com