Rotary machine coupling fault diagnosis method based on SCA and FastICA

A technology for coupling faults and rotating machinery, applied in the testing, measuring devices, instruments, etc. of machine/structural components, which can solve problems such as errors and erroneous conclusions, and achieve the effect of effective extraction, improvement of signal-to-noise ratio, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

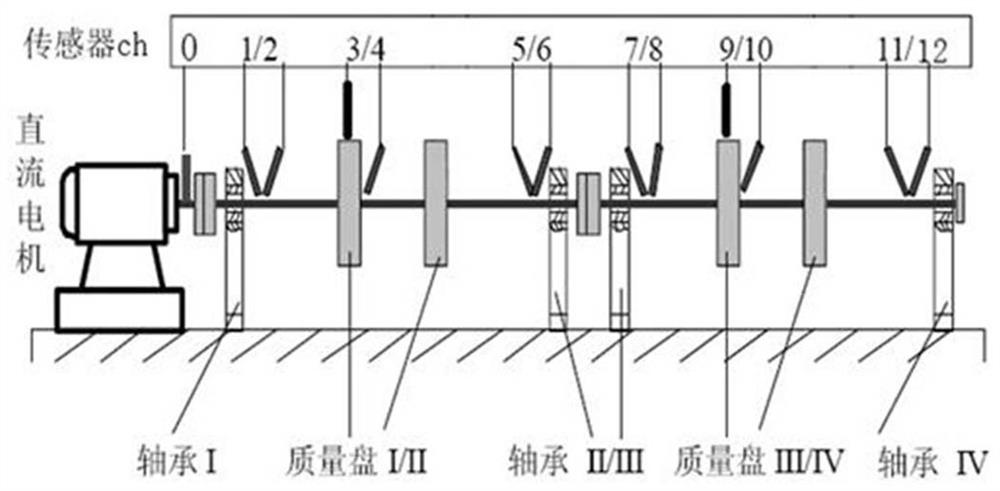

[0079] Example: figure 1 The simulation diagram of the experimental platform of the present invention is given.

[0080] The process is as follows:

[0081] Establish a noise-containing blind source separation model, and perform q times of cumulative processing on the low signal-to-noise ratio observation signal s(t);

[0082] Update the input signal s(t), calculate the effective average value of the noisy signal,

[0083] Equalize and smooth preprocess the signal;

[0084] Separation of blind source signals using FastICA;

[0085] Smooth the separated signal and observe the separation result;

[0086] Analyze signal characteristics and perform fault diagnosis.

[0087] more specific:

[0088] First: Use the acceleration sensor to test the rotating mechanical equipment to obtain its aliased coupling vibration signal;

[0089] Second: The observed signal is a low signal-to-noise ratio signal y(t), and a noise-containing blind source separation model is established;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com