Cable service life detection machine

A testing machine and life-span technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of shortening the service life of cables, high cost, dragging cables, etc., to improve accuracy, convenient operation, and increase tensile force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

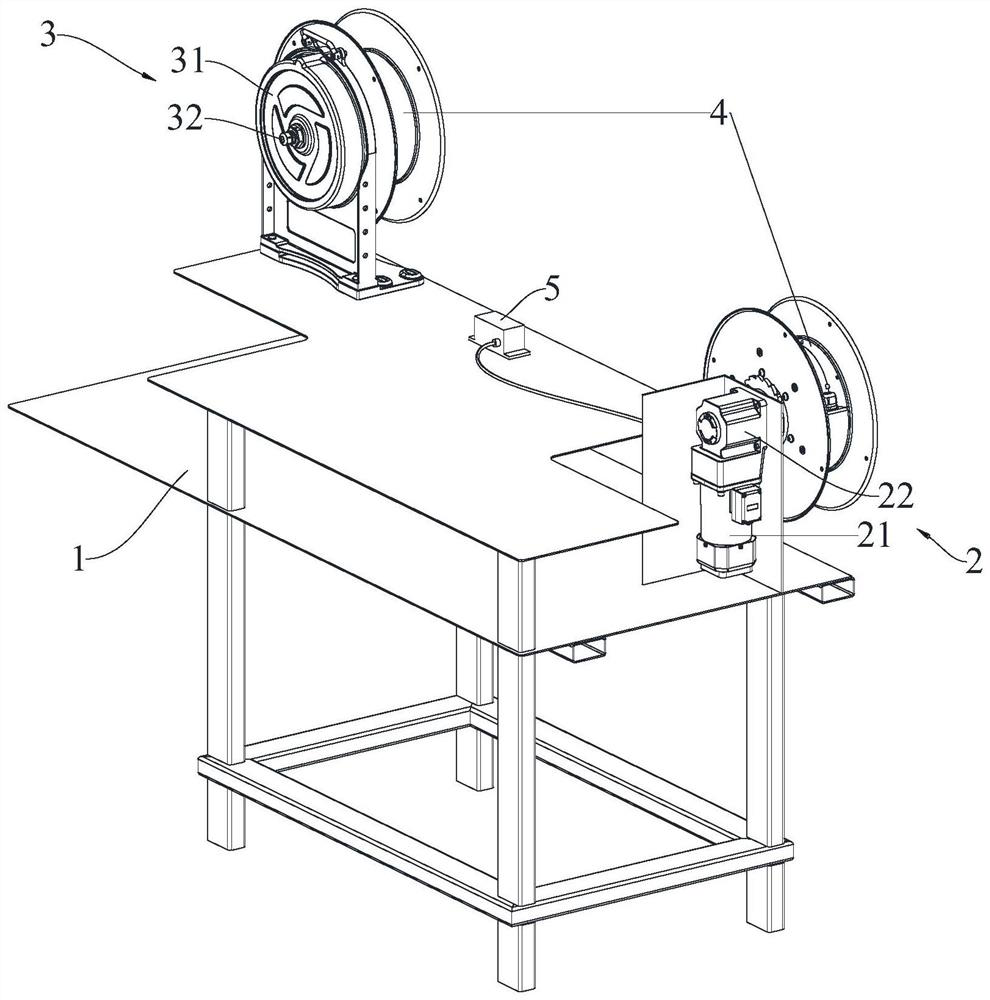

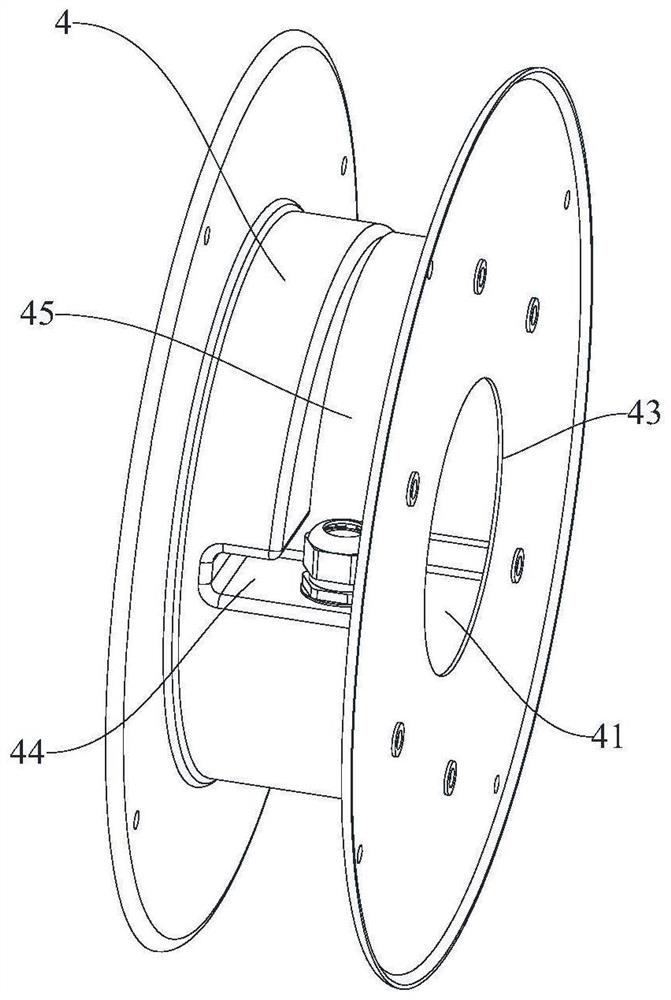

[0032] Embodiment one: refer to Figure 1-5 , a cable service life testing machine, including a frame 1, a driving part 2, a resistance part 3, two reels 4, an electronic meter 5 and two locking joints 6. Such as figure 1 As shown, the driving member 2 includes a driving motor 21 and a transmission mechanism 22, the driving motor 21 is fixed on the frame 1 by screws, the output shaft of the driving motor 21 is connected with the input end of the transmission mechanism 22, and the output end of the transmission mechanism 22 passes through The screw is installed and fixed on the axis of a wire reel 4, so that the rotation of the drive motor 21 and the transmission mechanism 22 drive the wire reel 4 to rotate, thereby realizing that the wire reel 4 is rotatably arranged on the frame 1, its structure is simple, and the motor speed controller can be used to accurately control the start and stop of the drive motor 21, as well as the forward and reverse rotation, and the operation i...

Embodiment 2

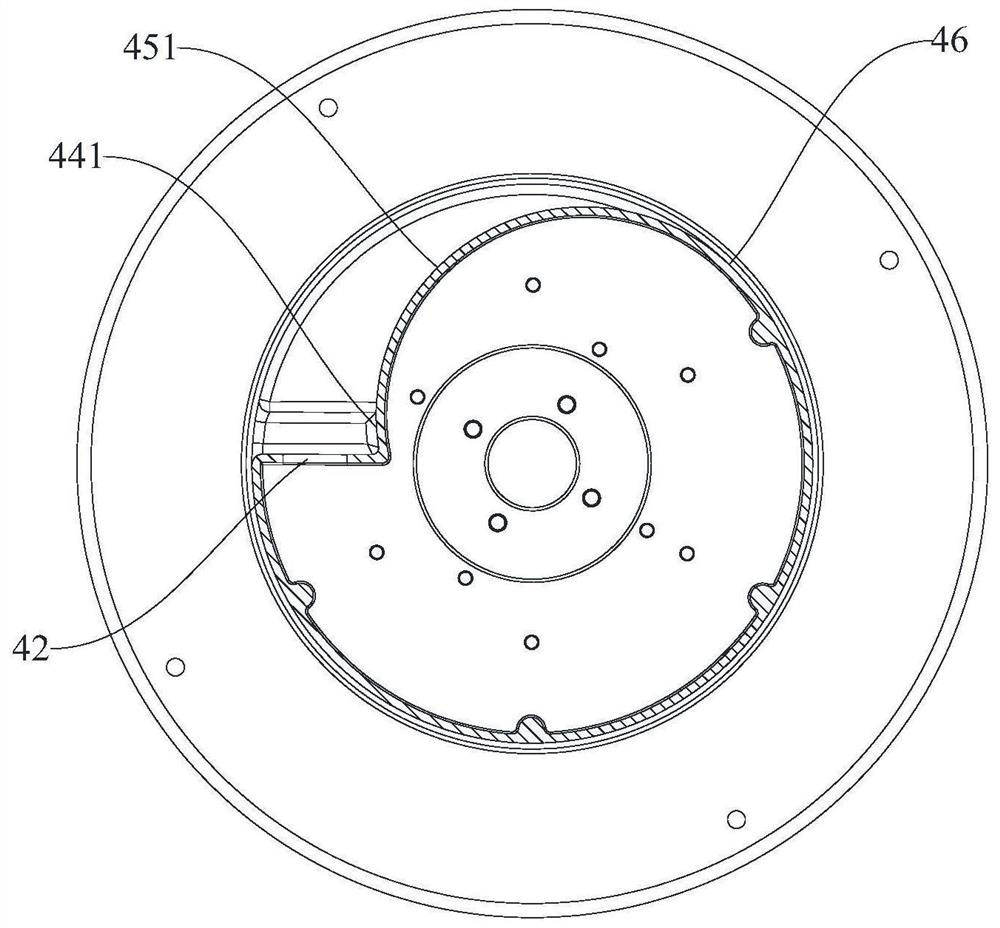

[0035] Embodiment two: refer to Figure 6-7 , implement the detection machine described in one, and also include a detection device 7, the detection device 7 includes a multimeter 71, two insulating support frames 72, two conductive columns 73 of a cylindrical structure, and two conductive sleeves 74 of an annular structure; The opening 43 is arranged on the axis of the reel 4 , and the two conductive columns 73 are respectively arranged on the axis of the two reels 4 , and one end of the two conductive columns 73 penetrates into a receiving cavity 41 through an opening 43 , respectively. The other ends of the two conductive posts 73 are respectively connected to the frame 1 through an insulating support frame 72, and the two conductive posts 73 are electrically connected to the multimeter 71; the two conductive sleeves 74 are respectively arranged in the two accommodating cavities 41 and the inner ring surfaces of the two conductive sleeves 74 are respectively rotatably arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com