Method for predicting broaching force of fir-shaped tooth profile finish broach

A prediction method, a fir tree-type technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large errors in analytical methods and simulation methods, and achieve the effect of simple modeling process and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

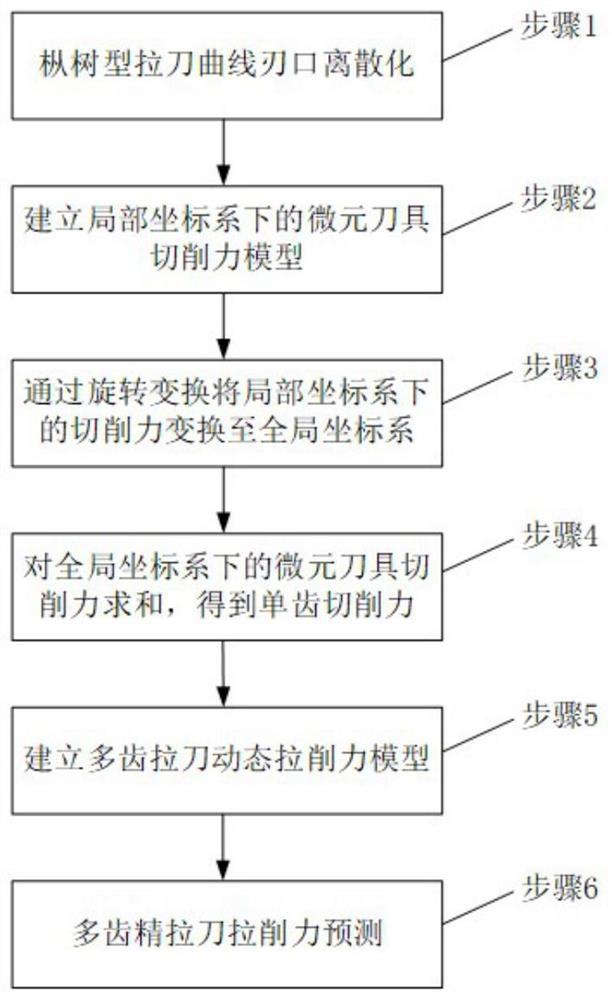

[0024] Such as figure 1 As shown, this embodiment relates to a method for predicting the broaching force of a fir tree-shaped tooth profile finishing broach, and the specific steps include:

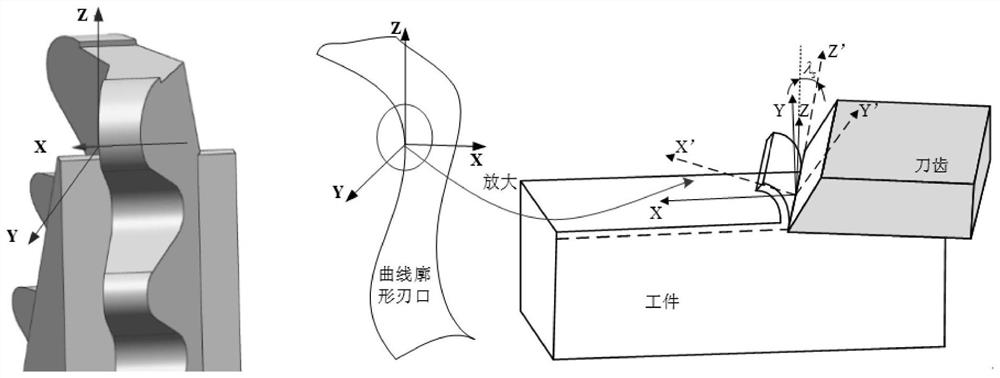

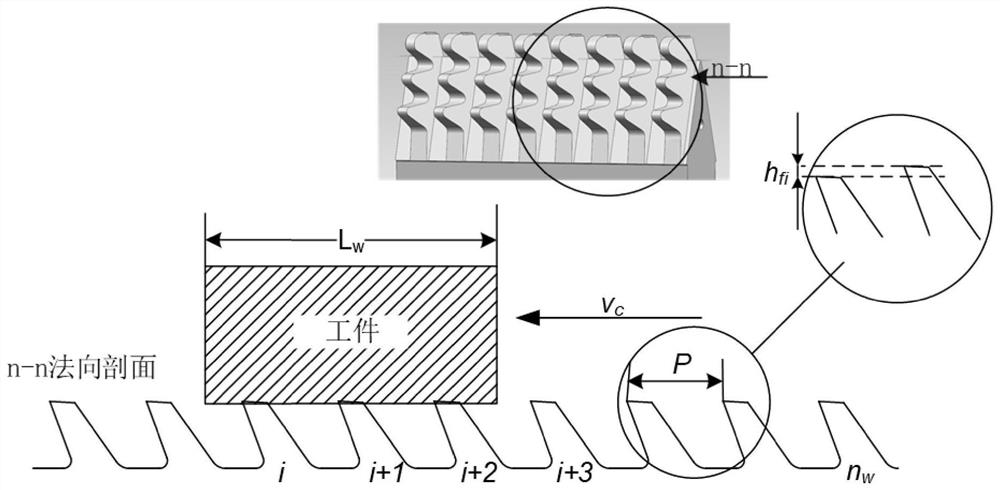

[0025] Step 1: Discretization of the edge of the fir tree broach curve: if figure 2 As shown, first the cutting edge is discretized into multiple single-edged micro-element tools. Combined broach by N 1 group of broaches, each group of broaches consists of N 2 segments, and each segment has a total of N 3 teeth, the tooth number is k, k=1,2,3,...,N 3 . For example, the kth tooth is discretized into microelements, and each microelement is numbered n, n=1, 2, 3,...,N.

[0026] Step 2: Establish the cutting force model of the microelement tool in the local coordinate system. In the local coordinate system of the cutting edge, according to the principle of bevel cutting, the tangential force, normal force and axial force of the discretized micro-element tool are respectively f ti , f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap