3D barrel-shaped vacuum insulation panel and heat preservation container

A vacuum insulation panel, 3D technology, applied in the field of thermal insulation materials, can solve the problems of inconspicuous VIP performance, insufficient cost performance, and limited VIP application, etc., and achieve the effects of improving thermal insulation performance and application scenarios, improving thermal insulation effect, and increasing thermal insulation duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

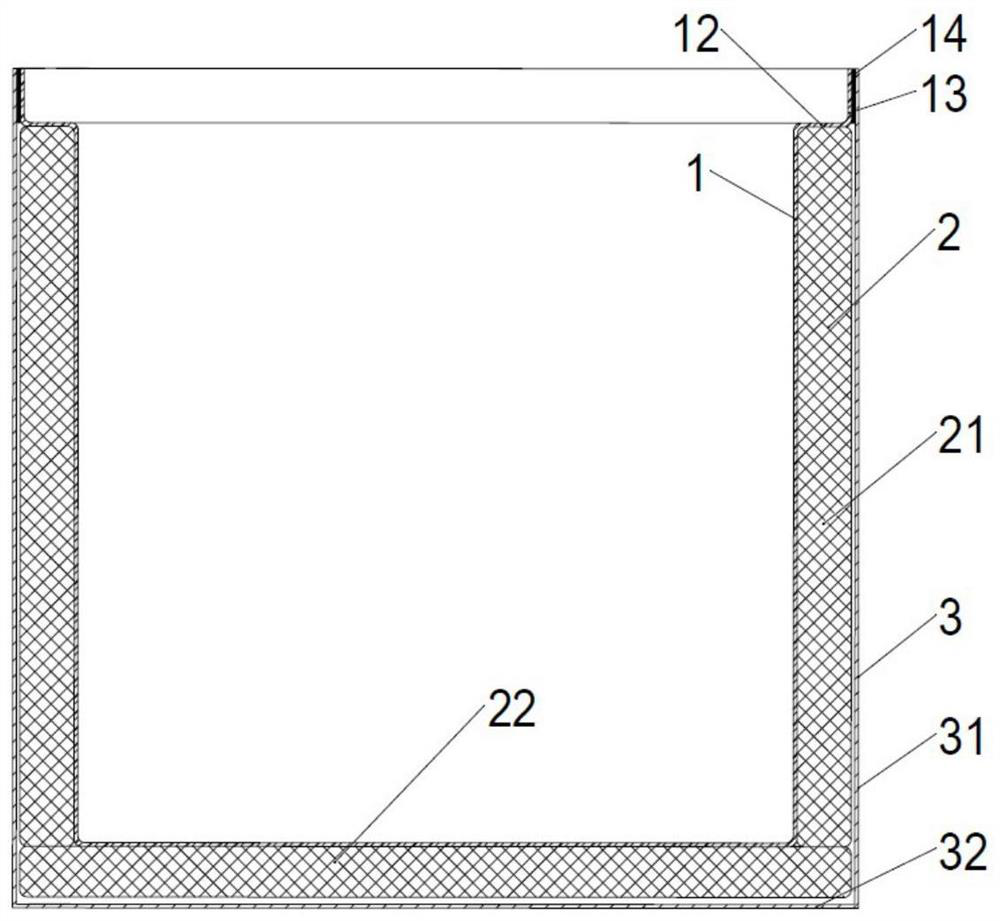

[0019] A 3D barrel type vacuum insulation panel such as figure 1 As shown, it includes an inner tank 1, an intermediate core material 2, and an outer barrel-shaped barrier film 3; the 3DVIP has an accommodating cavity and an opening; The outer extension forms an extension surface 12 , and an extension surface 13 is formed at the extension edge along the axial direction of the opening, and a sealing ring 14 is provided on the side of the extension surface 13 facing the barrier film.

[0020] The liner 1 is a metal liner, which is formed by stamping and stretching or welded, and does not leak air under vacuum conditions. The intermediate core material 2 is integrally formed of gas-silicon core material, or the intermediate core material includes a circular side wall glass fiber core material and a circular bottom surface glass fiber core materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com