Fluoroplastic-coated hose forming process and device

A molding device and molding process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

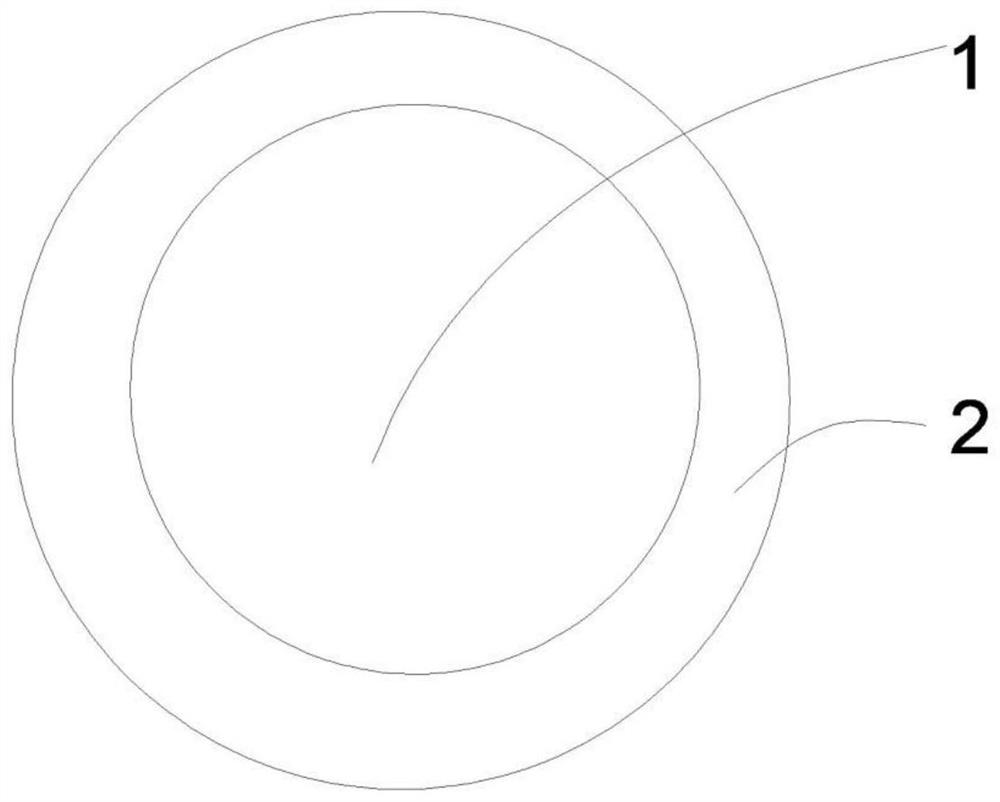

Image

Examples

specific Embodiment 1

[0031] Specific embodiment 1: the temperature of the oven is heated to 80°; the wall thickness of the fluorine plastic hollow hose is 1.5mm, and the inner diameter is 15mm. The connection is closed, the other end is sealed with a plug, and the pressure is increased to 0.5Mpa; after the fluoroplastic hose is heated in the oven for 3 minutes, the hose is pulled into the cooling box by the tractor, and the cooling box is filled with normal temperature water; at this time The inner diameter of the fluoroplastic hose becomes 17mm and can be maintained; put the silicone hose with an outer diameter of 15mm into the fluoroplastic hose; put the fluoroplastic hose into the 80° oven for three minutes and then take it out. Because the fluoroplastic hose has the characteristics of expansion and reduction, after 24 hours of storage, the inner diameter of the fluoroplastic hose becomes 15mm again. At this time, the fluoroplastic hose is finished processing. It can be seen that the matching g...

specific Embodiment 2

[0032] Specific embodiment 2: the temperature of the oven is heated to 120°; the wall thickness of the fluorine plastic hollow hose is 2.5mm, and the inner diameter is 25mm, the output end of the air valve machine is connected to the adapter, and one end of the fluorine plastic hose is connected to the adapter The connection is closed, the other end is sealed with a plug, and the pressure is increased to 0.5Mpa; after the fluoroplastic hose is heated in the oven for 3 minutes, the hose is pulled into the cooling box by the tractor, and the cooling box is filled with normal temperature water; at this time The inner diameter of the fluoroplastic hose becomes 28mm and can be maintained; put the silicone hose with an outer diameter of 25mm into the fluoroplastic hose; put the fluoroplastic hose into the 120° oven for three minutes and then take it out. Because the fluorine plastic hose has the characteristics of expansion and reduction, after 24 hours of storage, the inner diameter...

specific Embodiment 3

[0033] Specific embodiment 3: the temperature of the oven is heated to 180°; the wall thickness of the fluorine plastic hollow hose is 3.5 mm, and the inner diameter is 37 mm. The connection is closed, the other end is sealed with a plug, and the pressure is increased to 0.5Mpa; after the fluoroplastic hose is heated in the oven for 3 minutes, the hose is pulled into the cooling box by the tractor, and the cooling box is filled with normal temperature water; at this time The inner diameter of the fluoroplastic hose becomes 40mm and can be maintained; put the silicone hose with an outer diameter of 37mm into the fluoroplastic hose; put the fluoroplastic hose into the 180° oven for three minutes and then take it out. Because the fluorine plastic hose has the characteristics of expansion and reduction, after 24 hours of storage, the inner diameter of the fluorine plastic hose becomes 37mm. At this time, the fluorine plastic hose is finished processing. It can be seen that the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com