Universal electromagnetic solenoid basic assembly and combined structures based on assembly

A technology of electromagnetic solenoids and basic components, applied in the fields of magnetic field/electric field water/sewage treatment, special treatment targets, water/sewage treatment, etc. Problems such as unsatisfactory scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

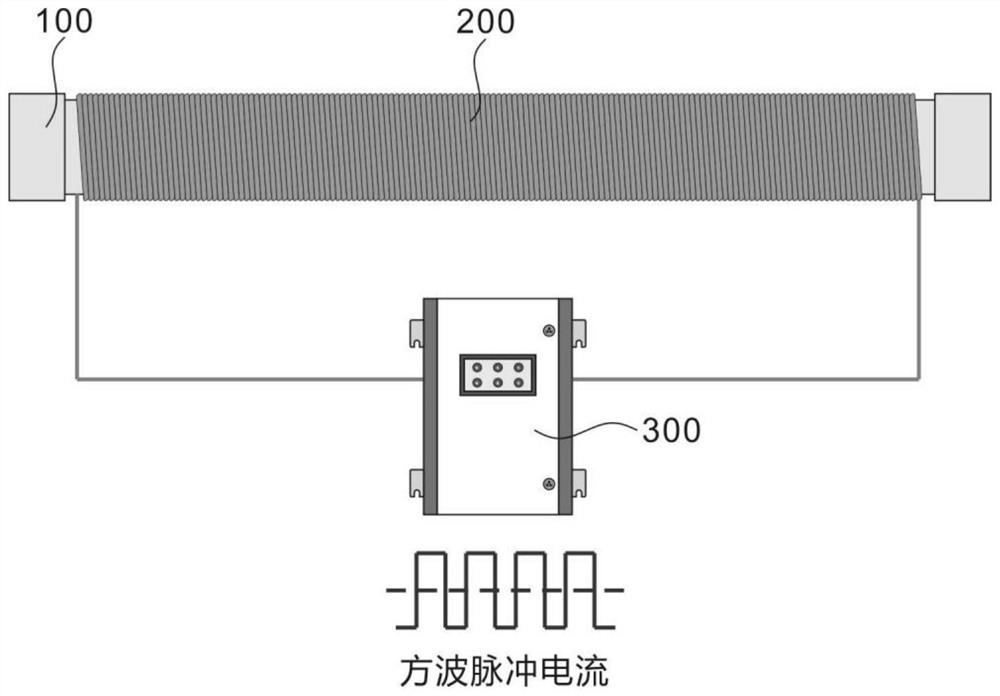

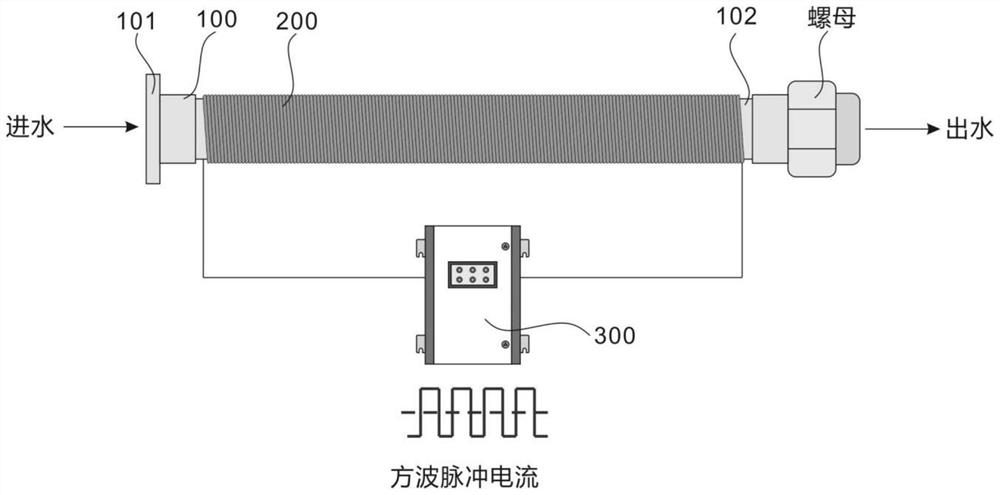

[0032] refer to figure 1 and figure 2 , is the first embodiment of the present invention, this embodiment provides a basic assembly of a general electromagnetic solenoid, the basic assembly of a general electromagnetic solenoid includes a core tube 100, an enameled wire winding 200 and a wave generator 300, and the enameled wire winding 200 is wound On the outer surface of the core tube 100, the wave generator 300 is electrically connected to the enameled wire winding 200. The wave generator 300 emits a pulse electromagnetic wave frequency in a specific frequency band, and generates a specific electromagnetic field through the enameled wire winding 200. The water flow of 100 has the effect of descaling and antiscaling.

[0033] Specifically, such as figure 1 , the core tube is a 100 hollow cylinder, and the water flows through the core tube 100, which is made of plastic, and the steel pipe has a strong blocking effect on pulsed electromagnetic waves, so that the magnetic fi...

Embodiment 2

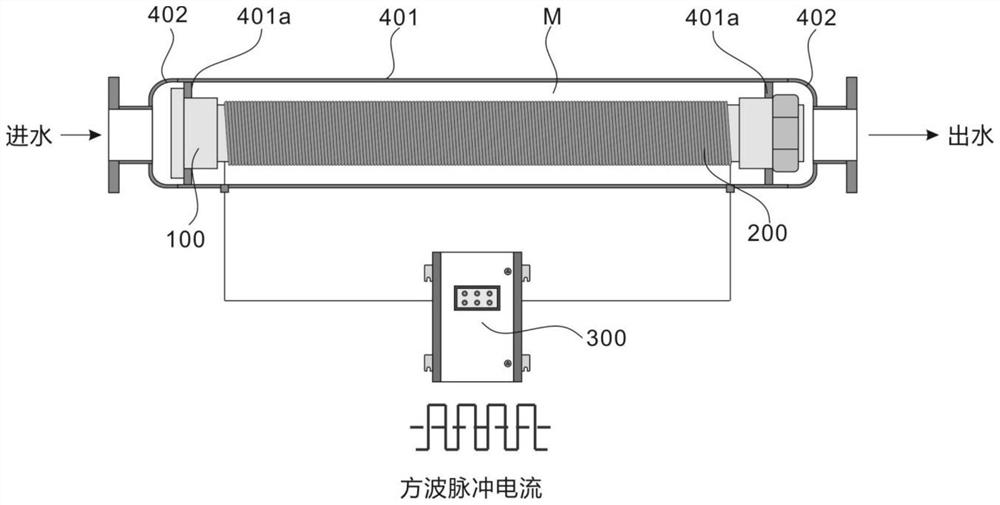

[0041] refer to image 3 , is the second embodiment of the present invention, which is different from the previous two embodiments in that: it also includes a housing 400 . In the previous embodiment, the general electromagnetic solenoid basic assembly includes a core tube 100, an enameled wire winding 200 and a wave generator 300, and the enameled wire winding 200 is wound on the outer surface of the core tube 100, and the wave generator 300 and the enameled wire The winding 200 is electrically connected, and the wave generator 300 emits pulsed electromagnetic waves of specific frequency bands to generate a specific electromagnetic field through the enameled wire winding 200 , so as to remove scale and prevent scale from the water flow passing through the core tube 100 .

[0042] Specifically, the core tube is 100 hollow cylinders, and water flows through the core tube 100, which is made of plastic, and the steel pipe has a strong blocking effect on pulsed electromagnetic wav...

Embodiment 3

[0049] refer to Figure 4~6 , is the third embodiment of the present invention, this embodiment provides a combination structure of general electromagnetic solenoid basic components, which includes a core tube 100, an enameled wire winding 200, a wave generator 300 and a fixed bracket 500, the core tube 100 . The enameled wire winding 200 and the wave generator 300 form a general electromagnetic solenoid basic assembly, and multiple general electromagnetic solenoid basic assemblies are fixed on the fixing bracket 500 .

[0050] Specifically, the core tube is a hollow cylinder 100, and water flows through the core tube 100, which is made of plastic. One end of the core tube 100 is provided with an end flange 101 extending axially outward along the core tube 100 , and the outer surface of the other end is provided with threads. The outer surface of the core tube 100 is provided with an annular groove 102 extending axially inwardly along the core tube 100 , and the enameled wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com