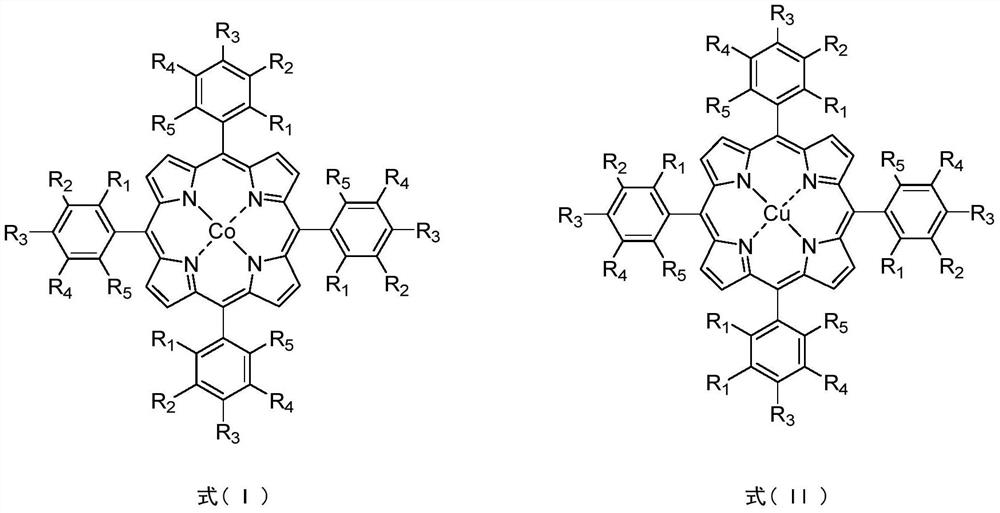

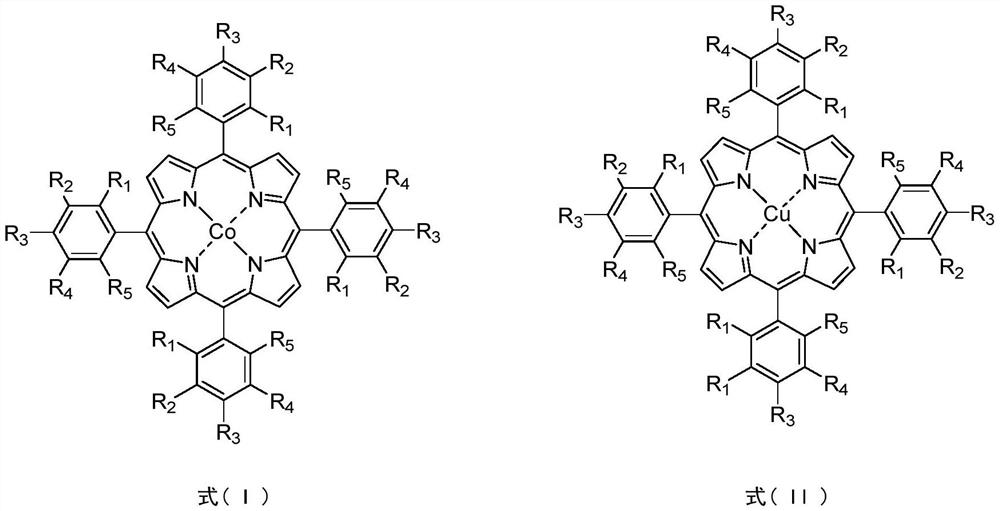

Method for catalytic oxidation of cycloalkane by bimetallic porphyrin MOFs PCN-222 (Co&Cu)

A bimetalloporphyrin, catalytic oxidation technology, applied in chemical instruments and methods, catalytic reaction, oxidation reaction preparation, etc., can solve the problem of reducing the selectivity of cycloalkyl alcohol and cycloalkyl ketone, increasing the uncontrollability of the reaction system, and the goal Problems such as poor product selectivity, to achieve the effect of high selectivity, inhibition of disordered diffusion, and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Synthesis of PCN-222(Co&Cu)-1: In a 35mL pressure-resistant reaction tube, T(4-COOH)PPCo(II)(0.0282g, 0.033mmol), T(4-COOH)PPCu(II)(0.0568 g, 0.067mmol), ZrCl 4 (0.1400g, 0.600mmol), benzoic acid (5.4000g, 44.3mmol) was dissolved in 16.0mL DMF, and ultrasonicated for 30min until all dissolved. The mixture was placed in an electric constant temperature blast drying oven at 120° C. for 48.0 hours of static reaction. After the reaction is complete, turn off the heating, cool to room temperature naturally, filter the crude product with suction and rinse with DMF and acetone successively, then transfer to a 10.0mL centrifuge tube, centrifuge for 5min in a low-speed centrifuge (3000rpm), pour out the upper layer, and dry the DMF Leach (3×8.0mL) until the upper layer is clear, dry acetone leaching (3×8.0mL) until the upper layer is clear, remove the solid in the lower layer, and dry at 90°C for 8.0h to obtain a brick red powder (0.0680g, 45.4% yield Rate).

Embodiment 2

[0029]Synthesis of PCN-222(Co&Cu)-2: In a 35mL pressure-resistant reaction tube, T(4-COOH)PPCo(II)(0.0424g, 0.05mmol), T(4-COOH)PPCu(II)(0.0425 g, 0.05mmol), ZrCl4 (0.1400g, 0.600mmol), benzoic acid (5.4000g, 44.3mmol) were dissolved in 16.0mL DMF, ultrasonic 30min until all dissolved. The mixture was placed in an electric constant temperature blast drying oven at 120° C. for 48.0 hours of static reaction. After the reaction is complete, turn off the heating, cool to room temperature naturally, filter the crude product with suction and rinse with DMF and acetone successively, then transfer to a 10.0mL centrifuge tube, centrifuge for 5min in a low-speed centrifuge (3000rpm), pour out the upper layer, and dry the DMF Leach (3×8.0mL) until the upper layer is clear, dry acetone leaching (3×8.0mL) until the upper layer is clear, remove the solid in the lower layer, and dry at 90°C for 8.0h to obtain a brick red powder (0.0687g, 45.2% yield Rate).

Embodiment 3

[0031] Synthesis of PCN-222(Co&Cu)-3: In a 35mL pressure-resistant reaction tube, T(4-COOH)PPCo(II)(0.0565g, 0.067mmol), T(4-COOH)PPCu(II)(0.0284 g, 0.033mmol), ZrCl 4 (0.1400g, 0.600mmol), benzoic acid (5.400g, 44.3mmol) was dissolved in 16.0mL DMF, ultrasonic 30min until all dissolved. The mixture was placed in an electric constant temperature blast drying oven at 120° C. for 48.0 hours of static reaction. After the reaction is complete, turn off the heating, cool to room temperature naturally, filter the crude product with suction and rinse with DMF and acetone successively, then transfer to a 10.0mL centrifuge tube, centrifuge for 5min in a low-speed centrifuge (3000rpm), pour out the upper layer, and dry the DMF Leach (3×8.0mL) until the upper layer is clear, dry acetone and leaching (3×8.0mL) until the upper layer is clear, remove the lower solid, and dry at 90°C for 8.0h to obtain a brick red powder (0.0697g, 45.8% yield Rate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com