Preparation method for high-temperature-resistant infrared low-emittance coating

A low-emissivity coating and high-temperature-resistant technology, applied in the field of infrared stealth, can solve problems such as poor thermal insulation performance, and achieve the effects of good thermal insulation performance, lower infrared radiation intensity, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

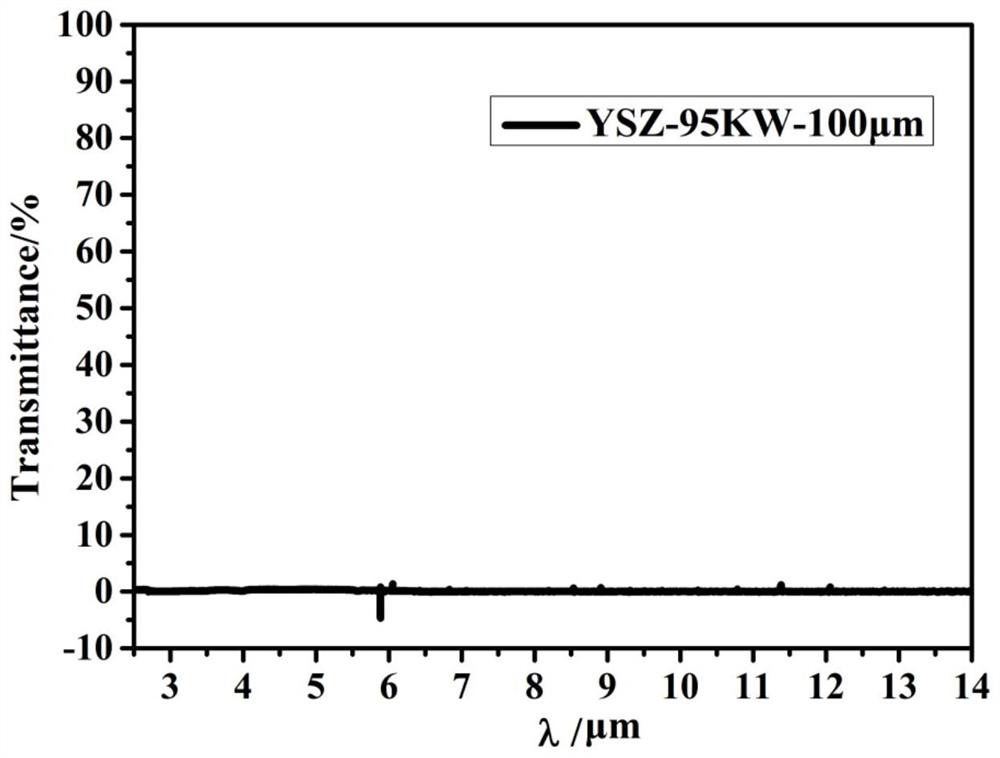

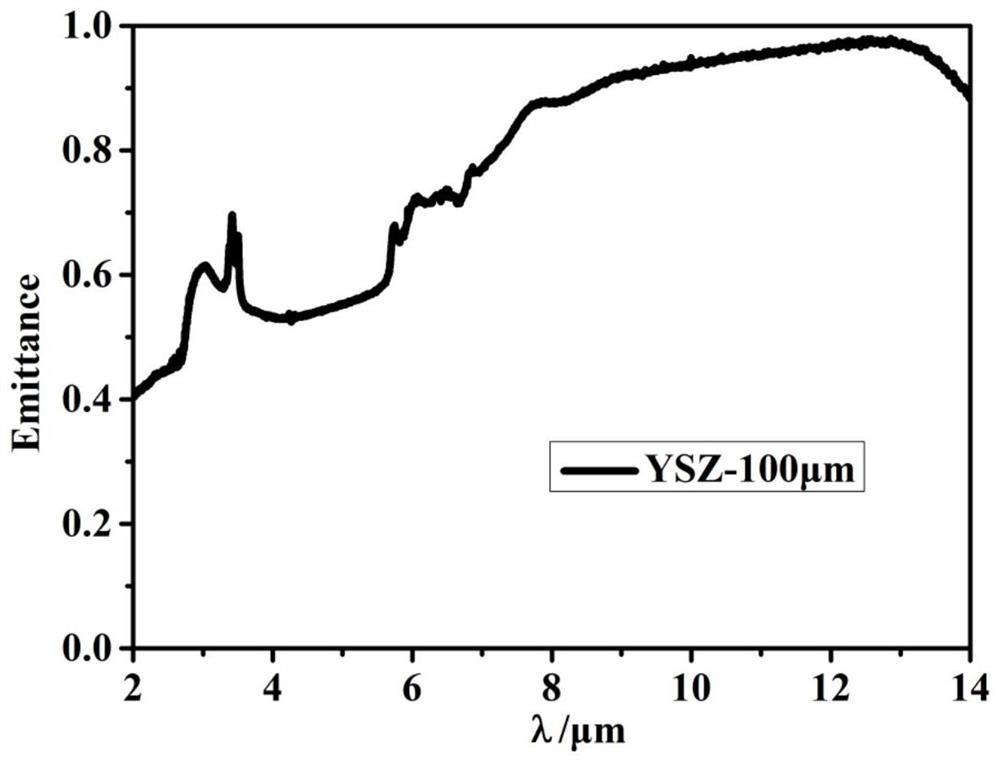

[0025] Example 1: Preparation of a YSZ coating with a thickness of 100 μm.

[0026] (1) Select YSZ powder with a purity of 99.9wt%, put it in a furnace at 90°C and dry it for later use.

[0027] (2) The surface of the graphite substrate is pretreated, and the surface of the substrate is ultrasonically cleaned with acetone and alcohol.

[0028] (3) Carry out spraying step 1 gained YSZ powder on the graphite base prepared in step 2 with plasma spraying technology, prepare YSZ coating, spraying power is 95KW, and spraying distance is 100mm, gas used is argon, nitrogen, hydrogen. Among them, the flow rate of argon gas is 150SCFH, the flow rate of nitrogen gas is 100SCFH, and the flow rate of hydrogen gas is 120SCFH. The thickness of the prepared YSZ coating is 100 μm.

[0029] (4) The YSZ coating prepared by plasma spraying in step 3 is annealed in air, the annealing temperature is 800°C, and the time is 2h.

[0030] The high-temperature low-emissivity coating prepared in Examp...

Embodiment 2

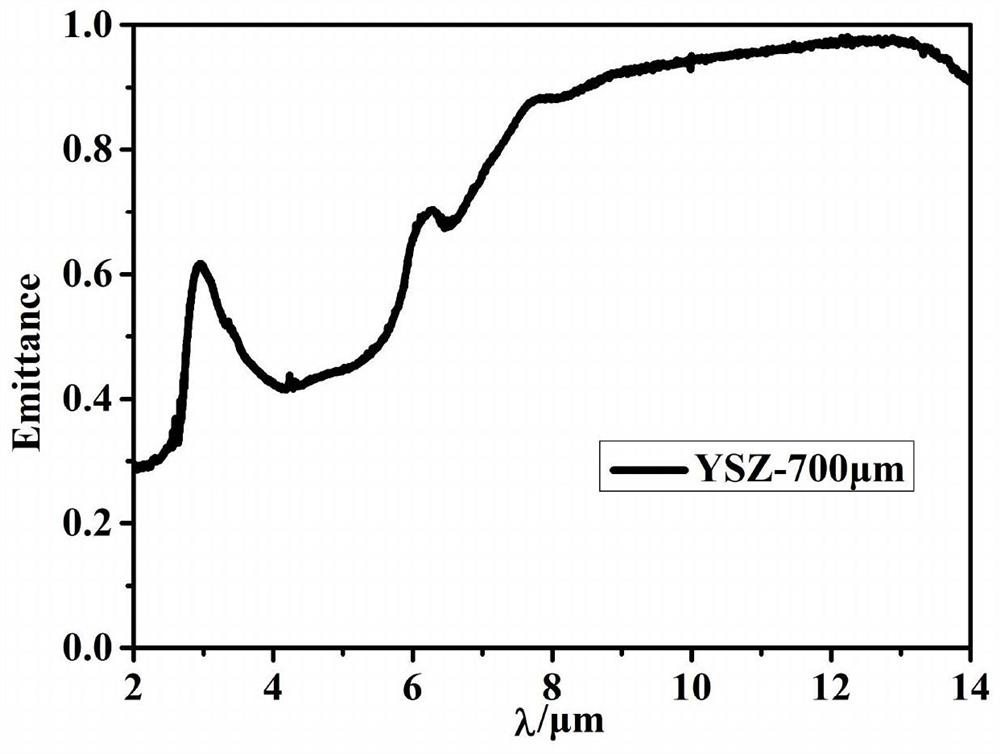

[0031] Example 2: Preparation of a YSZ coating with a thickness of 700 μm.

[0032] (1) Select YSZ powder with a purity of 99.9wt%, put it in a furnace at 90°C and dry it for later use.

[0033] (2) The surface of the graphite substrate is pretreated, and the surface of the substrate is ultrasonically cleaned with acetone and alcohol.

[0034] (3) Carry out spraying step 1 gained YSZ powder on the graphite base prepared in step 2 with plasma spraying technology, prepare YSZ coating, spraying power is 95KW, and spraying distance is 100mm, gas used is argon, nitrogen, hydrogen. Among them, the flow rate of argon gas is 150SCFH, the flow rate of nitrogen gas is 100SCFH, and the flow rate of hydrogen gas is 120SCFH. The thickness of the prepared YSZ coating is 700 μm.

[0035] (4) The YSZ coating prepared by plasma spraying in step 3 is annealed in air, the annealing temperature is 800°C, and the time is 2h.

[0036] The emissivity situation of the high-temperature low-emissivi...

Embodiment 3

[0038] (1) Select YSZ powder and NiCoCrAlY powder with a purity of 99.9wt%, put them into a furnace at 90°C and dry them for later use.

[0039] (2) The surface of the graphite substrate is pretreated, and the surface of the substrate is ultrasonically cleaned with acetone and alcohol.

[0040] (3) carry out spraying step 1 gained YSZ powder and NiCoCrAlY powder on the graphite base prepared in step 2 with plasma spraying technology, prepare YSZ / NiCoCrAlY composite coating, spraying power is 65KW, and spraying distance is 100mm, gas used is Argon, Nitrogen and Hydrogen. Among them, the flow rate of argon gas is 170SCFH, the flow rate of nitrogen gas is 80SCFH, and the flow rate of hydrogen gas is 75SCFH. The thickness of the prepared YSZ coating is 50 μm, and the volume ratio of YSZ to NiCoCrAlY is 1:14.

[0041] (4) carry out spraying step 1 gained YSZ powder on the YSZ / NiCoCrAlY composite coating prepared in step 3 with plasma spraying technology, prepare YSZ coating, spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com