Constant-pressure piston type particle damper

A particle damper and particle damping technology, applied in shock absorbers, shock absorbers, friction shock absorbers, etc., can solve the problems of single energy dissipation mechanism, non-recoverable energy, and low collision efficiency, so as to improve collision efficiency , Reduce time lag, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

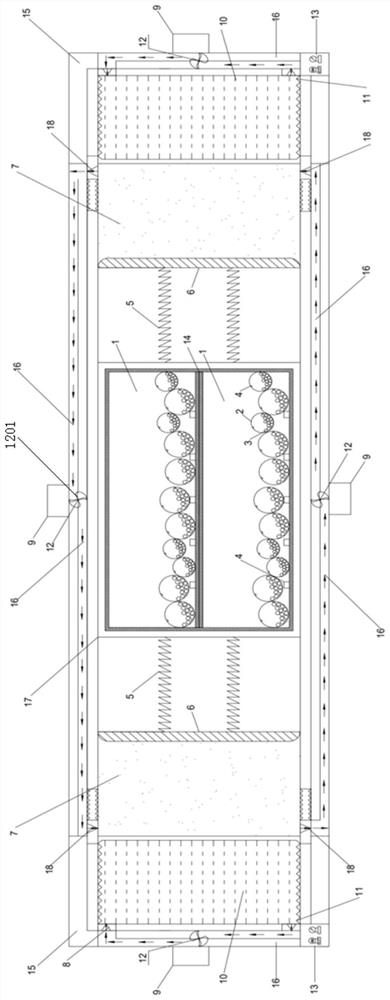

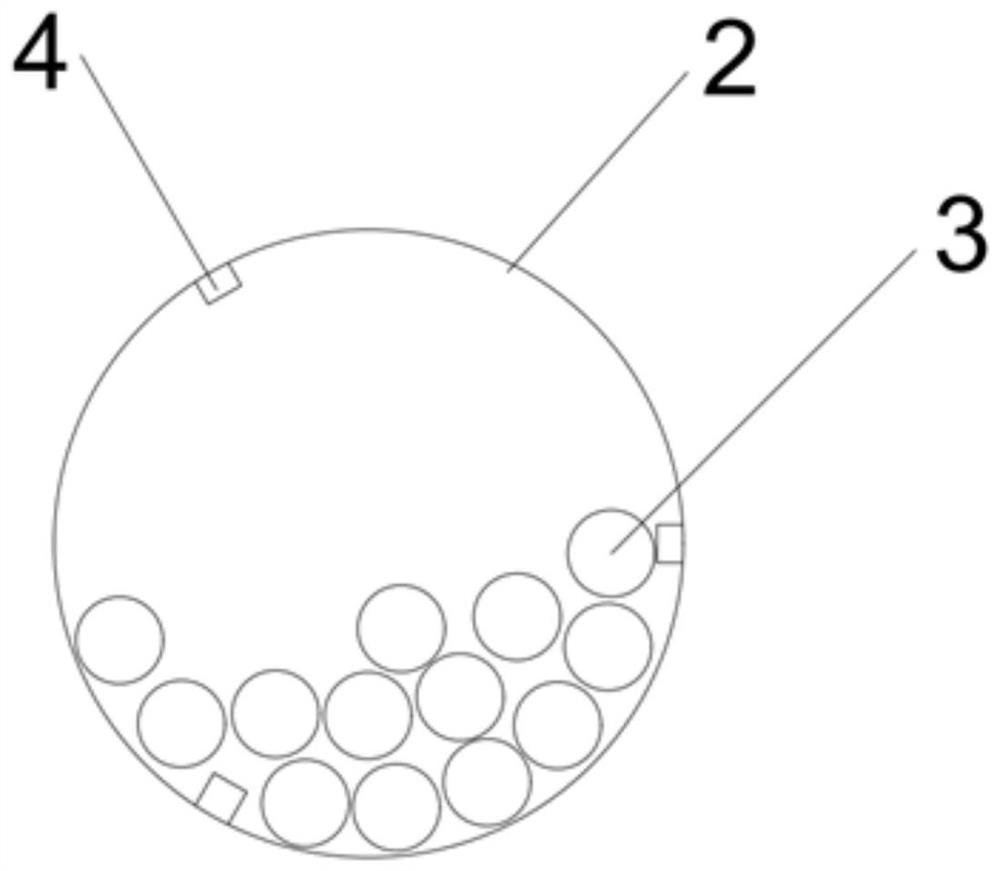

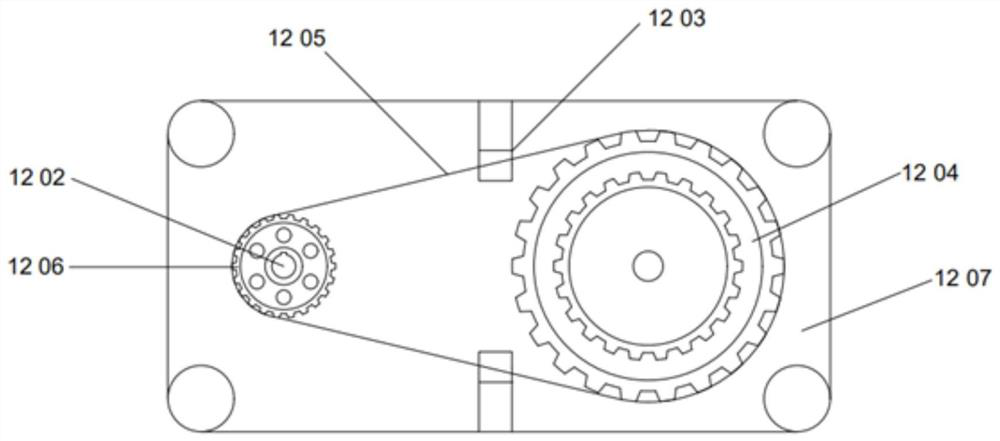

[0036] A controllable constant pressure piston type particle damper, the damper is fixed on the top of the structure to be damped, its structure is as follows figure 1 As shown, it includes a box 17 and a particle damping unit movable in the box 17. Both sides of the particle damping unit are symmetrically connected with baffles 6, and the particle damping unit and the inner side of the baffle 6 are connected by springs. 5 connection, the baffle can move along the inner wall of the box body 17, and an airtight storage chamber is formed between the outside of the baffle plate 6 and the box body 17, and liquid and / or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com