Evaporative cooling unit with frost prevention structure

An evaporative cooling and anti-frost technology, applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as snow accumulation on metal filters, clogging of metal filters, and reduction of air intake on the outdoor circulation side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

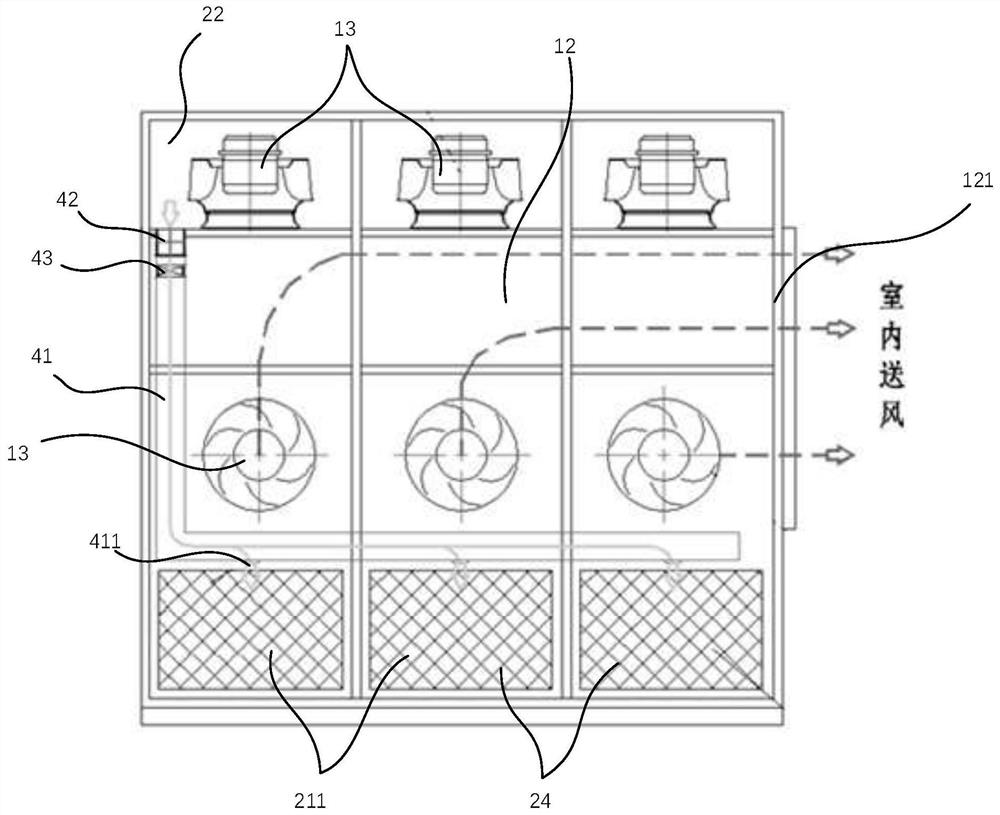

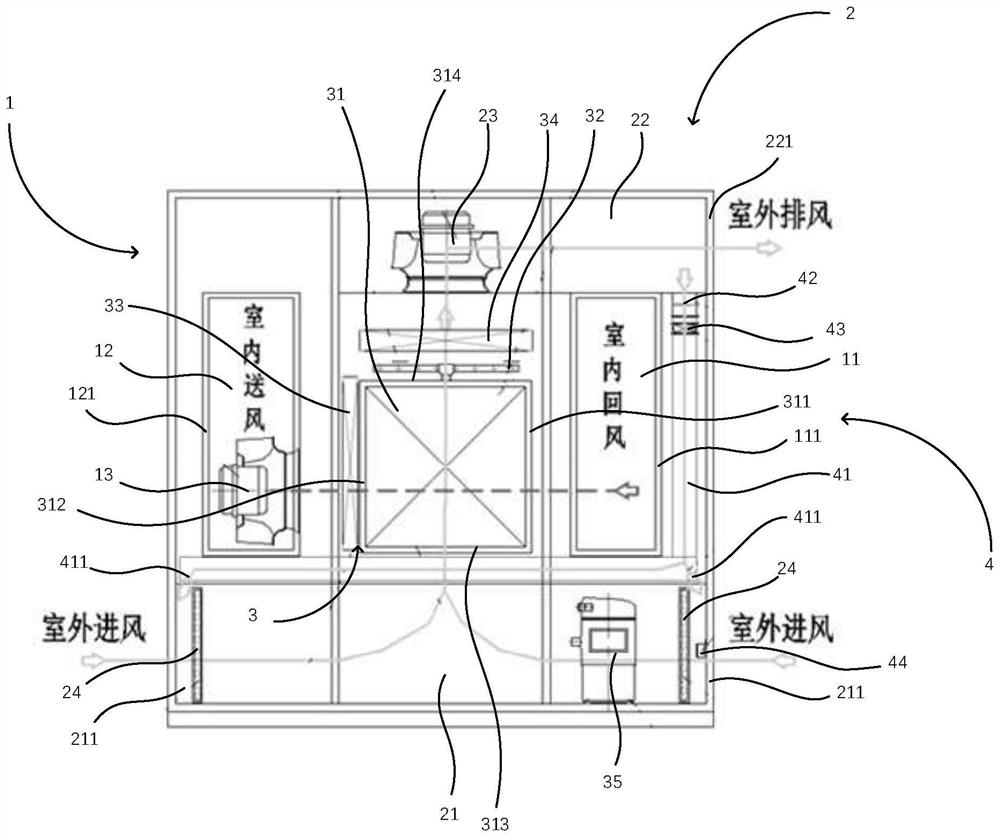

[0034] In the following, the specific structure of the evaporative cooling unit in Embodiment 1 will be described in detail with reference to the drawings.

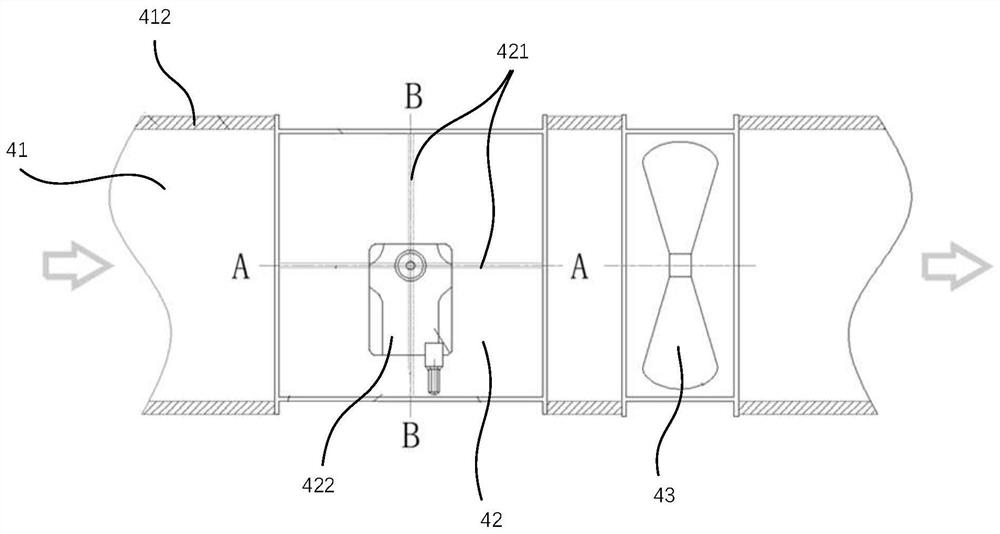

[0035] figure 1 It is a structural schematic diagram of one side of the air inlet filter screen of the evaporative cooling unit in Embodiment 1; figure 2 for figure 1 Schematic diagram of the structure of the evaporative cooling unit. like figure 1 , figure 2 As shown, the evaporative cooling unit includes: indoor circulation system 1, which can suck indoor air into the evaporative cooling unit and then discharge it into the room; outdoor circulation system 2, can suck outdoor air into the evaporative cooling unit and then discharge it outdoors; The refrigeration system 3 can cool the air in the indoor circulation system 1 and transfer heat to the air in the outdoor circulation system 2; the anti-frost system 4 can prevent the following metal filter screen 24 of the outdoor circulation system 2 from frosting Or fre...

Embodiment 2

[0046] The present application also provides a second embodiment. Below, the specific structure of the evaporative cooling unit in Embodiment 2 will be described in detail with reference to the drawings.

[0047] Figure 4 It is a structural schematic diagram of one side of the metal filter screen of the evaporative cooling unit in Embodiment 2; Figure 5 for Figure 4 Schematic diagram of the structure of the evaporative cooling unit. like Figure 4 Figure 5 As shown, the operation mode of the evaporative cooling unit in Embodiment 2 is the same as that in Embodiment 1, the difference lies in the arrangement of the individual systems and components. details as follows:

[0048] The evaporative cooling unit is in the shape of a cuboid as a whole. The heat exchanger 31 is in the shape of a cube and is inclined at the lower right corner at an angle of 45°. The indoor inlet 311 and the outdoor inlet are inclined upward, and the indoor outlet 312 and the outdoor outlet 314 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com