Thermal power plant low-load denitration system based on fused salt energy storage system

A technology for thermal power plants and energy storage systems, applied in the field of energy storage, can solve the problems that the inlet flue gas temperature of the SCR denitration device cannot be guaranteed, the operation requirements of the SCR catalyst cannot be met, and the pollutant emission standards cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail, convenient to understand the present invention clearly, but they are not construed as limiting the present invention.

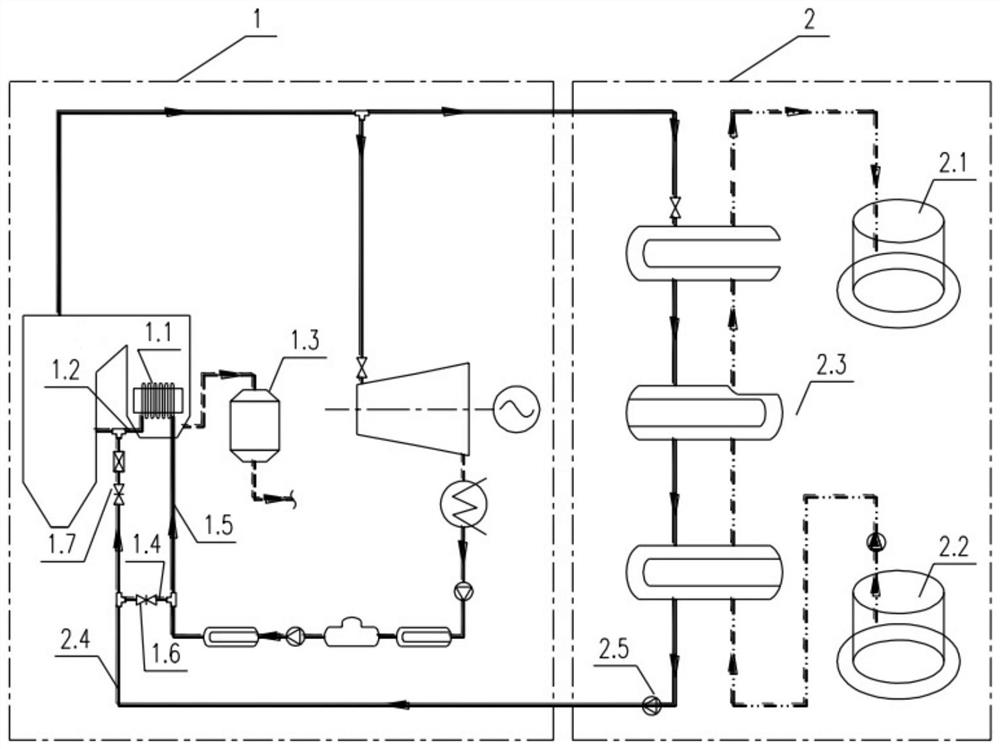

[0016] Such as figure 1 As shown, the present invention provides a low-load denitrification system for a thermal power plant based on a molten salt energy storage system. When the conventional thermal power generation system 1 is in deep peak-shaving and low-load operation, high-pressure steam enters the high-pressure steam molten salt energy storage system 2 for energy storage, which can reduce the steam intake of the steam turbine of the conventional thermal power generation system 1, thereby reducing power generation and realizing deep peak-shaving; After heat exchange between the high-pressure steam and the high-pressure steam molten salt energy storage system 2, it becomes high-pressure condensed water with a higher temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com