Swirl burner pulverized coal ignition distance measuring device based on slider-crank mechanism

A crank-slider mechanism and swirl burner technology are applied in measuring devices, temperature measurement of moving fluids, heat measurement, etc., which can solve problems such as lack of basis for adjusting the air distribution of burners, and ensure combustion stability and prevent The effect of burning loss and preventing fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

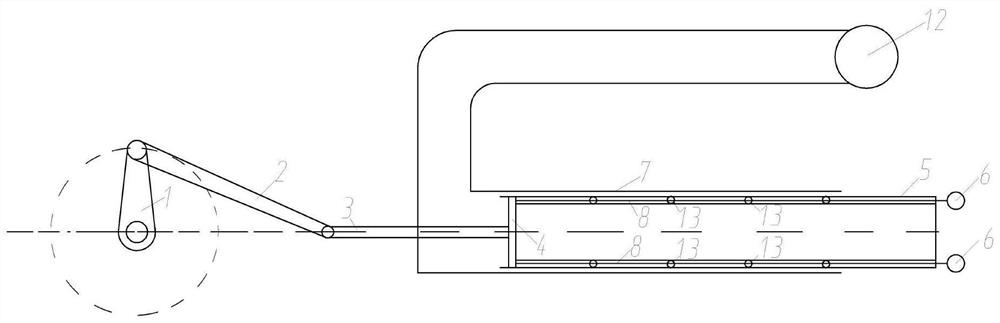

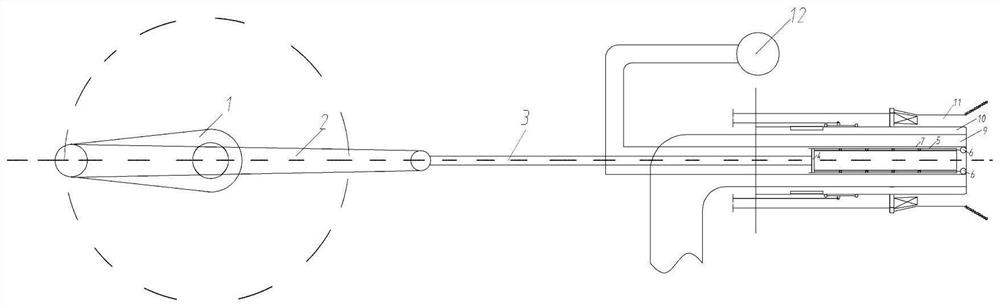

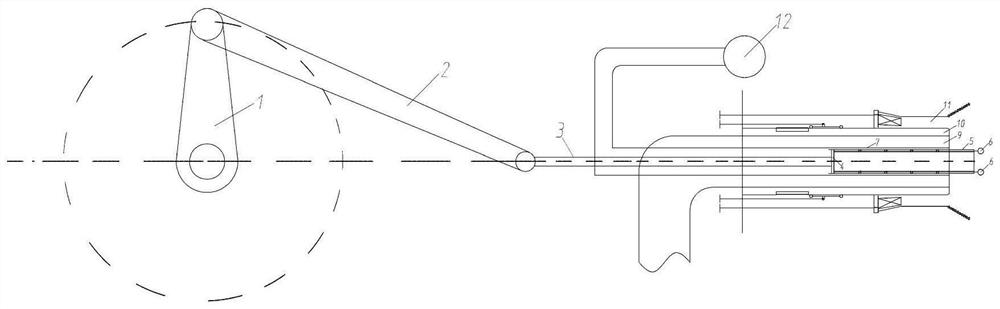

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] The ignition process of the pulverized coal flow in the utility boiler is roughly divided into three stages, which are the preparation stage before ignition, the combustion stage and the burnout stage, and the whole process is completed within about 2 seconds. The lowest temperature corresponding to when the pulverized coal starts to ignite is called the pulverized coal ignition temperature, and the engineering definition is greater than 800°C as the pulverized coal ignition temperature. Generally, the pulverized coal flow at the outlet of the swirl burner catches fire at about 300mm to 500mm away from the burner, and it should not exceed 500mm, but it should not be lower than 300mm.

[0034] The crank, connecting rod, and tie rod form the crank slider mechanism, and the motion state of each component is described when the crank rotates 360° clockwise....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com