Layered double hydroxide material system, preparation method thereof and application of layered double hydroxide material system

A double hydroxide, hydroxide technology, applied in the direction of drug combination, pharmaceutical formula, non-active ingredient medical preparations, etc., can solve the problems of non-targeting, reduced toxic and side effects, and high drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

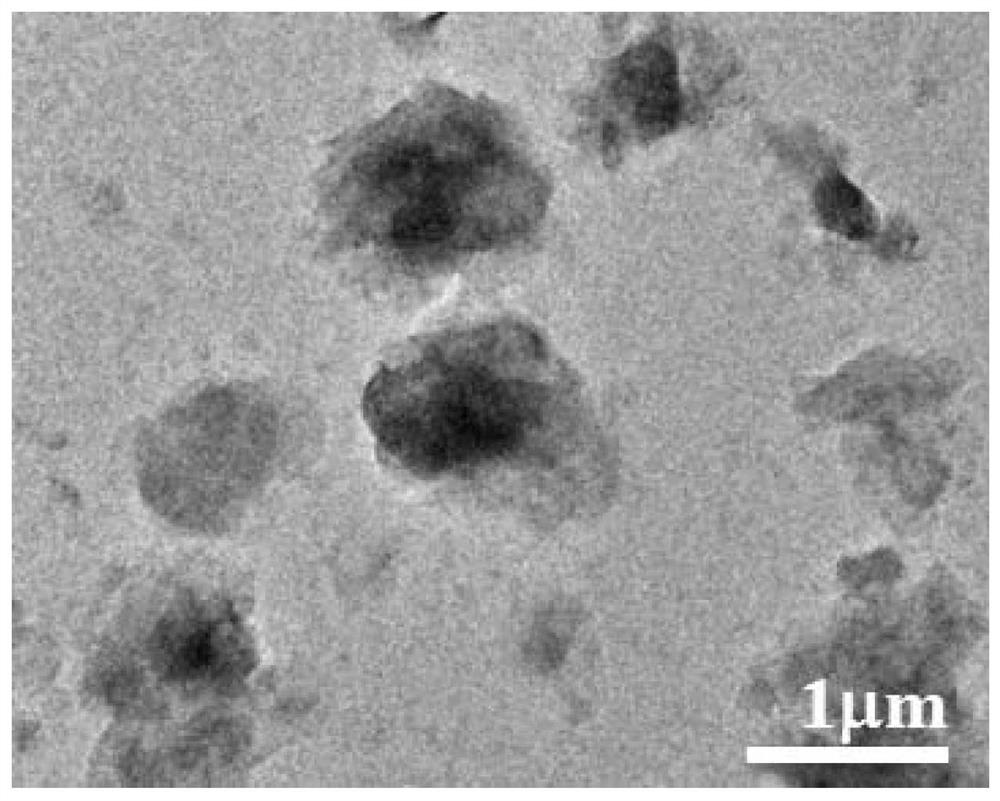

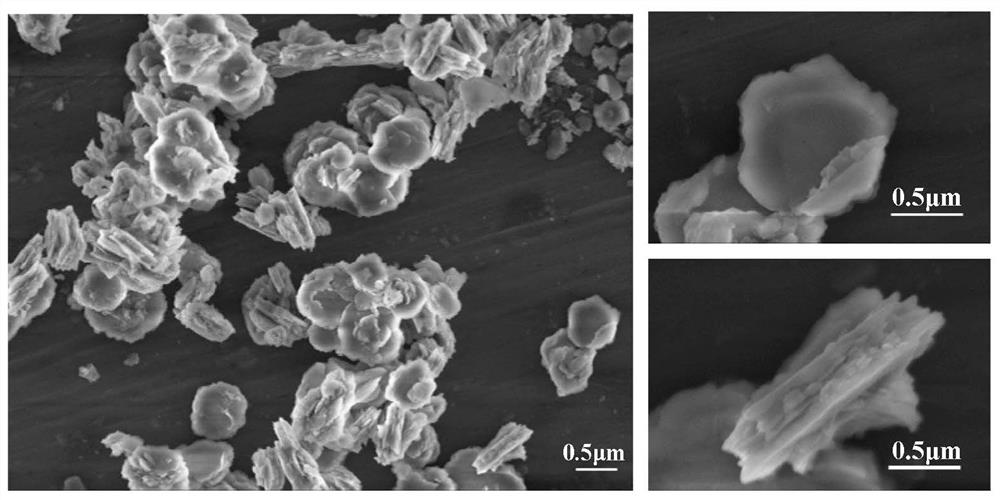

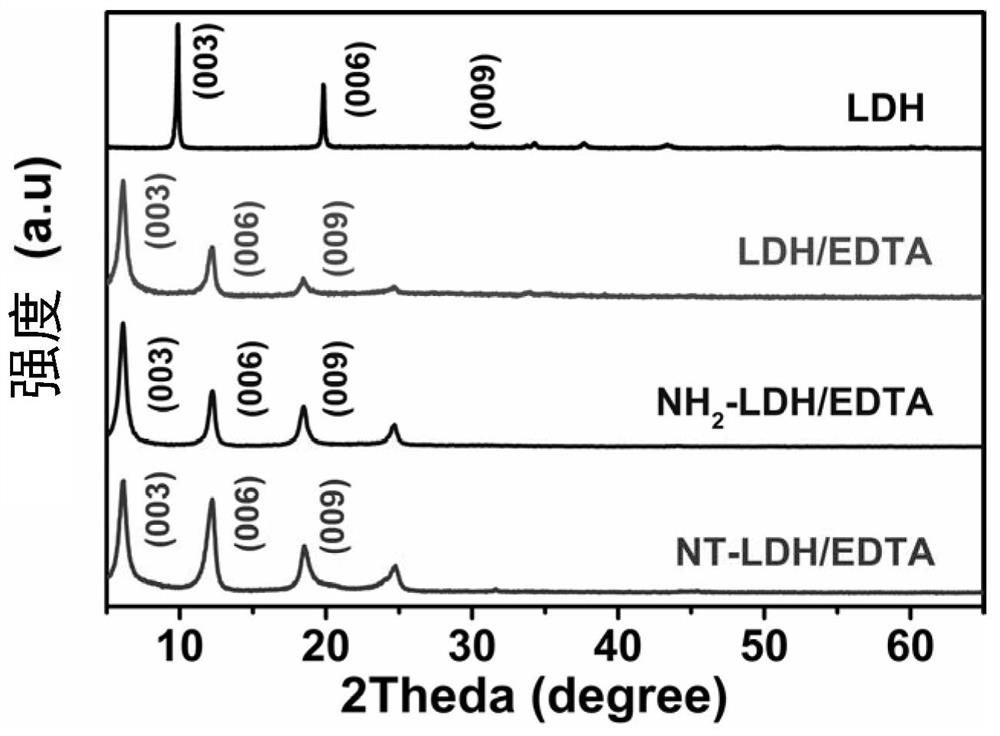

[0080]The preparation process of EDTA-loaded zinc aluminum layered double hydroxide (LDH / EDTA) is as follows: Weigh a certain amount of Zn(NO3)2·6H2O(0.594g), Al(NO3)3·9H2O(0.375g), NaNO3(0.085g) and cyclohexamethylenetetramine (HMT) (0.702g) were dissolved in 200mL of deionized water, magnetically stirred for 20min under the protection of high-purity argon atmosphere to exhaust the air, and then the solution was moved to a 120℃ oil bath Stir in the pot, reflux with high-purity argon as protective gas, and slowly add Na after 2h2H2EDTA solution (1.2mg dissolved in 50mL deionized water), continue to react at 80°C for 22h, finally the precipitate is collected by filtration and thoroughly washed with deionized water to obtain LDH / EDTA.

[0081]LDH / EDTA surface amination modification to obtain NH2-LDH / EDTA. The suspended hydroxyl groups on the surface of LDH are hydrolyzed and bonded to the silanic hydroxyl groups in APTES, and the surface is modified into suspended amino groups. The speci...

Embodiment 2

[0084]The preparation process of Zn-Al layered double hydroxide (LDH) is as follows: Weigh a certain amount of Zn(NO3)2·6H2O(0.594g), Al(NO3)3·9H2O(0.375g), NaNO3(0.085g) and cyclohexamethylenetetramine (HMT) (0.702g) were dissolved in 200mL of deionized water, magnetically stirred for 20min under the protection of high-purity argon atmosphere to exhaust the air, and then the solution was moved to a 120℃ oil bath Stir in the pot and reflux with cold water under the condition of high-purity argon as protective gas. After 2h, the temperature was changed to 80℃, and the reaction was continued for 22h. Finally, the precipitate was collected by filtration and thoroughly washed with deionized water to obtain LDH. The process of surface amination modification and NT connection in Example 2 is basically the same as that in Example 1, except that NT-LDH without EDTA is used. Among them, the loading mass of neurotensin in NT-LDH is 3.9 wt% of the mass of zinc aluminum layered double hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com