Coal slime drying and crushing device and drying and crushing method

A technology of crushing device and crushing method, applied in drying gas arrangement, chemical instruments and methods, drying and other directions, can solve the problems of "clumping, flammability, low drying efficiency, etc., to reduce water content and flammability, reduce The effect of clumping balls and increasing the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

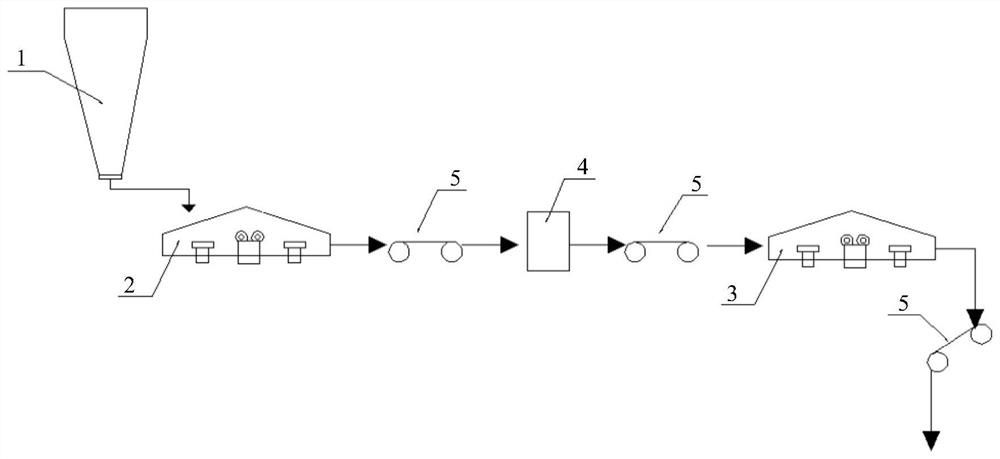

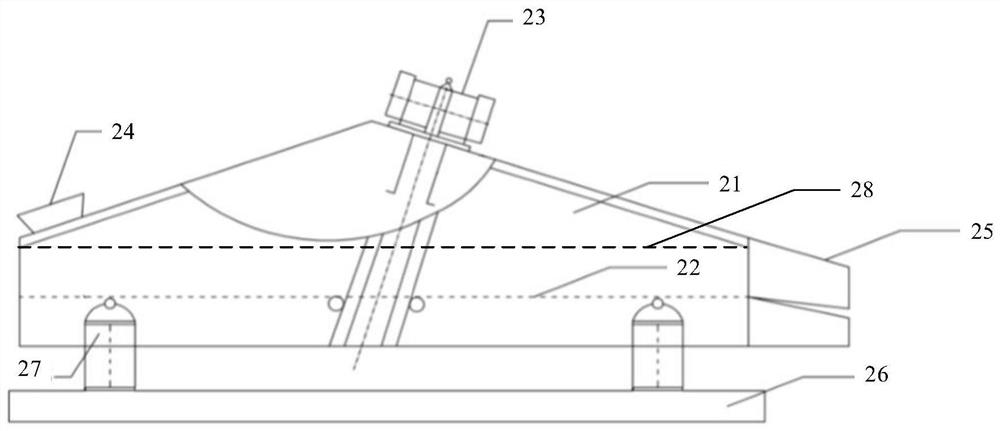

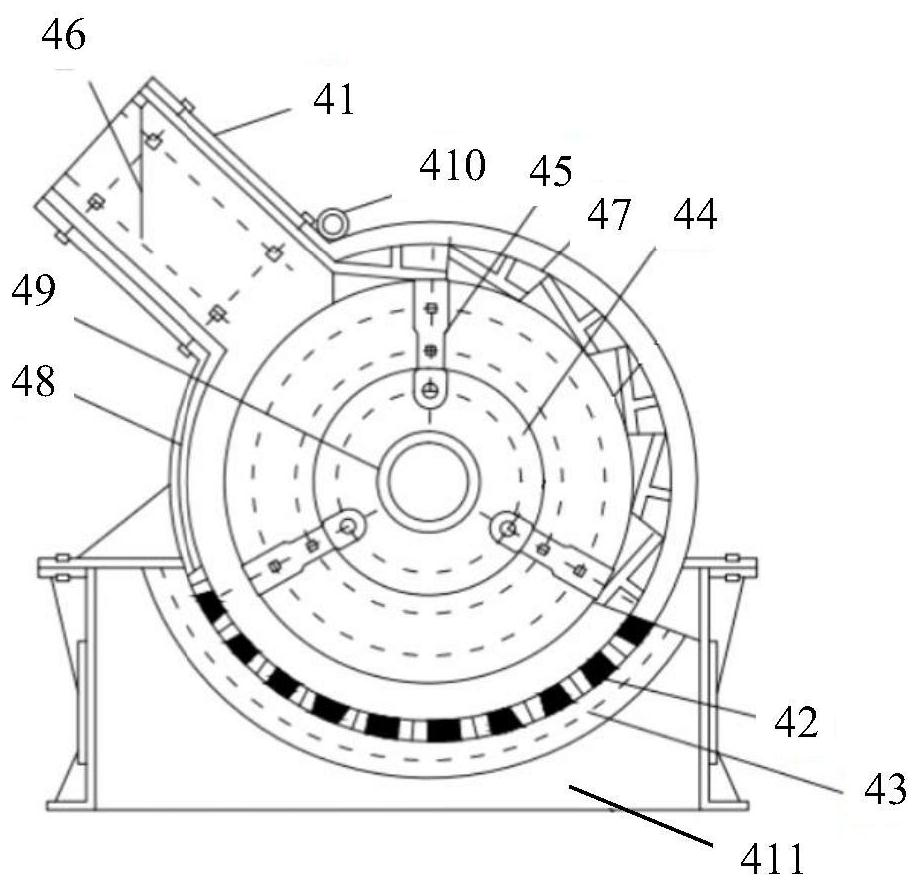

[0058] This embodiment provides a coal slime drying and crushing device, see Figure 1 to Figure 5 , including a feeder 1, a primary vibrating screen 2, a crusher 4 (for example, an impact crusher) and a secondary vibrating screen 3 arranged in sequence, and heat carrier gas (such as , hot air), the primary vibrating screen 2 is used for primary drying of coal slime, the crusher 4 is used for primary crushing of coal slime, and the secondary vibrating screen 3 is used for secondary drying and secondary crushing of coal slime. The discharge port of machine 1 is connected with the feed port of primary vibrating screen 2, the discharge port of primary vibrating screen 2 is connected with the feed port of crusher 4, the discharge port of crusher 4 is connected with the feed port of secondary vibrating screen 3 Feed port connection.

[0059] During implementation, the large-grained coal slime enters the feeder 1, and evenly enters the primary vibrating screen 2 from the feeder 1 u...

Embodiment 2

[0088] This embodiment provides a method for drying and crushing coal slime, comprising the following steps:

[0089] Step S1: using a primary vibrating sieve to dry the coal slime once to obtain a primary dried coal slime;

[0090] Step S2: Using a crusher to crush the primary dried coal slime to obtain the primary crushed coal slime;

[0091] Step S3: performing secondary drying and secondary crushing on the primary crushed coal slime by using a secondary vibrating screen to obtain a coal slime product.

[0092] Compared with the prior art, the beneficial effects of the coal slime drying and crushing method provided in this embodiment are basically the same as those of the coal slime drying and crushing device provided in Embodiment 1, and will not be repeated here.

[0093] In order to utilize the waste heat of the hot carrier gas, the above method also includes the following steps: circulating the hot carrier gas discharged from the secondary vibrating screen to the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com