LC40 lightweight aggregate concrete and preparation method thereof

A technology of lightweight aggregate concrete and concrete mixer, which is applied in the field of concrete preparation, can solve the problems of low strength of all-light concrete, inability to guarantee the thermal insulation effect of all-light concrete, and inability to effectively use it, so as to achieve enhanced bonding effect and enhanced bonding relationship, the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

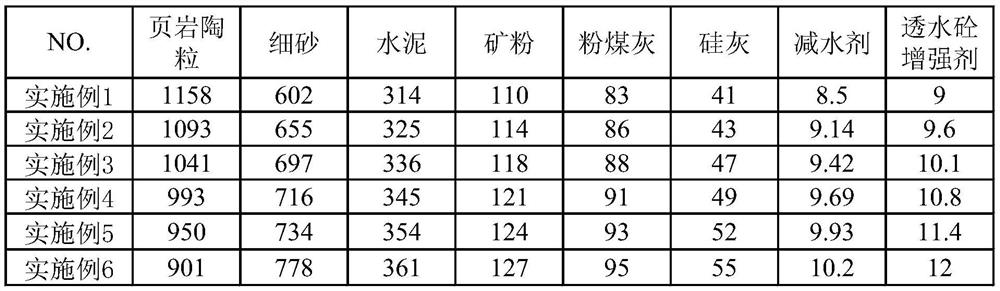

[0030]The LC40 lightweight aggregate concrete disclosed in the embodiments of the present application includes shale ceramsite, fine sand, cement, water reducing agent, mineral admixture and water. The shale ceramsite uses crushed shale ceramsite; mineral The admixtures include fly ash, mineral powder, and silica fume. The specific weight parts of each component are shown in Table 1.

[0031]In addition, the shale ceramsite used adopts continuous gradation, and the particle size of shale ceramsite is 5-10mm. The solid content of the used water reducing agent is 20%, and the water reducing rate is greater than 30%.

[0032]The preparation method of the LC40 lightweight aggregate concrete includes the following steps:

[0033]S1: Put cement, mineral admixture, shale ceramsite, water, and water reducing agent into the concrete mixer for mixing to obtain the initial mixed material;

[0034]S2: Put the shale ceramsite into the initial mixed material obtained in S1 for mixing to obtain LC40 lightweig...

Embodiment 2-6

[0039]The difference from Example 1 is that the weight parts of each component included are different, and the detailed values are shown in Table 1.

Embodiment 7

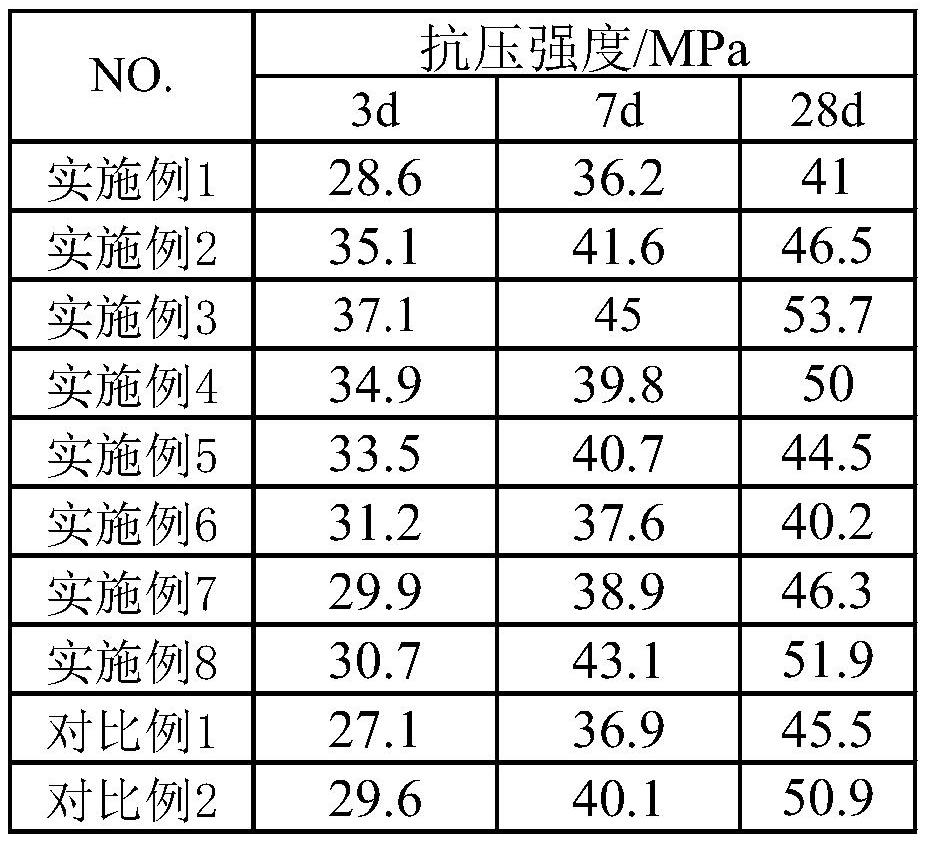

[0041]The difference from Example 3 is that the shale ceramsite used in this embodiment is a conventional shale ceramsite that is not crushed shale ceramsite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com