Method for improving dynamic characteristics of concrete by applying multi-scale fiber structure body

A technology of dynamic characteristics and structure, applied in the field of concrete processing, can solve the problems of poor interface performance of carbon fiber surface, and achieve the effect of good dispersion, improved concrete strength and dynamic strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

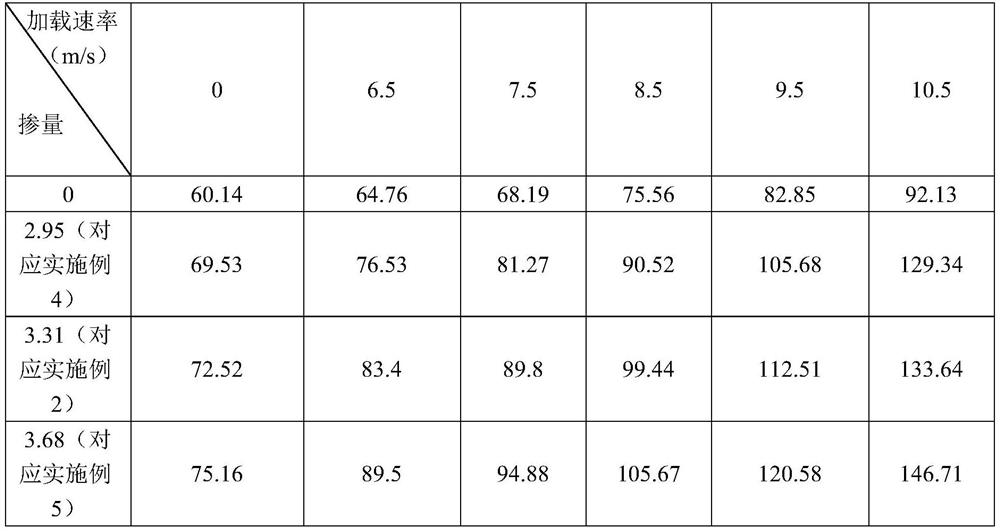

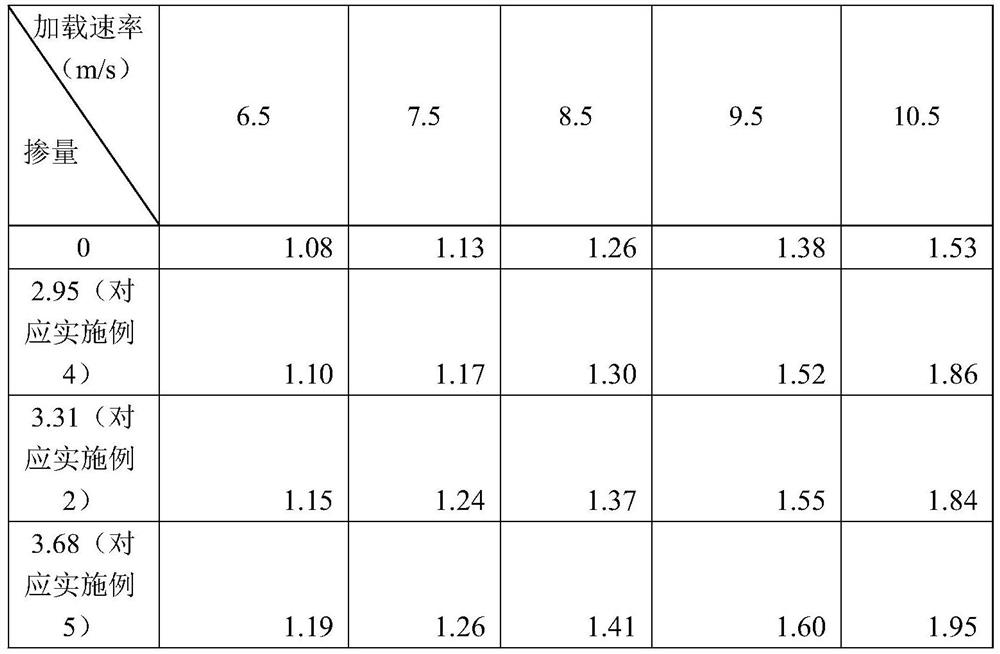

[0030] A method of using a multi-scale fiber structure to improve the dynamic properties of concrete, comprising the steps of:

[0031] (1) Weighing of raw materials:

[0032] Take the following raw materials by corresponding parts by weight for subsequent use:

[0033] Cement 364.00kg, silica fume 25.20kg, fly ash 125.00kg, sand 691.00kg, gravel 1032.00kg, water 175.00kg, water reducing agent 5.10kg, multi-scale fiber structure 2.95kg;

[0034] (2) Preparation of multi-scale fiber structure water dispersion solution:

[0035] Mix the water weighed in step (1) with the water reducer, then add the multi-scale fiber structure, and then add sodium lauryl sulfate, and ultrasonically disperse for 15 minutes. After 15 minutes, the multi-scale fiber structure water dispersion solution is ready for use; The add-on of described sodium lauryl sulfate is 1% of water gross mass;

[0036] (3) Preparation of multi-scale fiber structure cement mortar:

[0037] Mix and stir the cement, si...

Embodiment 2

[0051] A method of using a multi-scale fiber structure to improve the dynamic properties of concrete, comprising the steps of:

[0052] (1) Weighing of raw materials:

[0053] Take the following raw materials by corresponding parts by weight for subsequent use:

[0054] Cement 370.00kg, silica fume 27.50kg, fly ash 129.00kg, sand 705.00kg, gravel 1045.00kg, water 178.00kg, water reducing agent 5.20kg, multi-scale fiber structure 3.31kg;

[0055] (2) Preparation of multi-scale fiber structure water dispersion solution:

[0056] Mix the water weighed in step (1) with the water reducer, then add the multi-scale fiber structure, and then add sodium lauryl sulfate, and ultrasonically disperse for 15 minutes. After 15 minutes, the multi-scale fiber structure water dispersion solution is ready for use; The add-on of described sodium lauryl sulfate is 1.3% of water gross mass;

[0057] (3) Preparation of multi-scale fiber structure cement mortar:

[0058] Mix and stir the cement, ...

Embodiment 3

[0072] A method of using a multi-scale fiber structure to improve the dynamic properties of concrete, comprising the steps of:

[0073] (1) Weighing of raw materials:

[0074] Take the following raw materials by corresponding parts by weight for subsequent use:

[0075] Cement 375.00kg, silica fume 28.50kg, fly ash 134.00kg, sand 712.00kg, gravel 1058.00kg, water 180.00kg, water reducing agent 5.40kg, multi-scale fiber structure 3.68kg;

[0076] (2) Preparation of multi-scale fiber structure water dispersion solution:

[0077] Mix the water weighed in step (1) with the water reducer, then add the multi-scale fiber structure, and then add sodium lauryl sulfate, and ultrasonically disperse for 15 minutes. After 15 minutes, the multi-scale fiber structure water dispersion solution is ready for use; The add-on of described sodium lauryl sulfate is 1.5% of water gross mass;

[0078] (3) Preparation of multi-scale fiber structure cement mortar:

[0079] Mix and stir the cement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com