Cloth cleaning equipment for textile processing

A technology for cleaning equipment and fabrics, which is applied to the processing of textile materials, the processing of textile material drums, and the processing of liquid/gas/steam textile materials. It can improve work efficiency, avoid rapid water loss and hardening, and improve drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

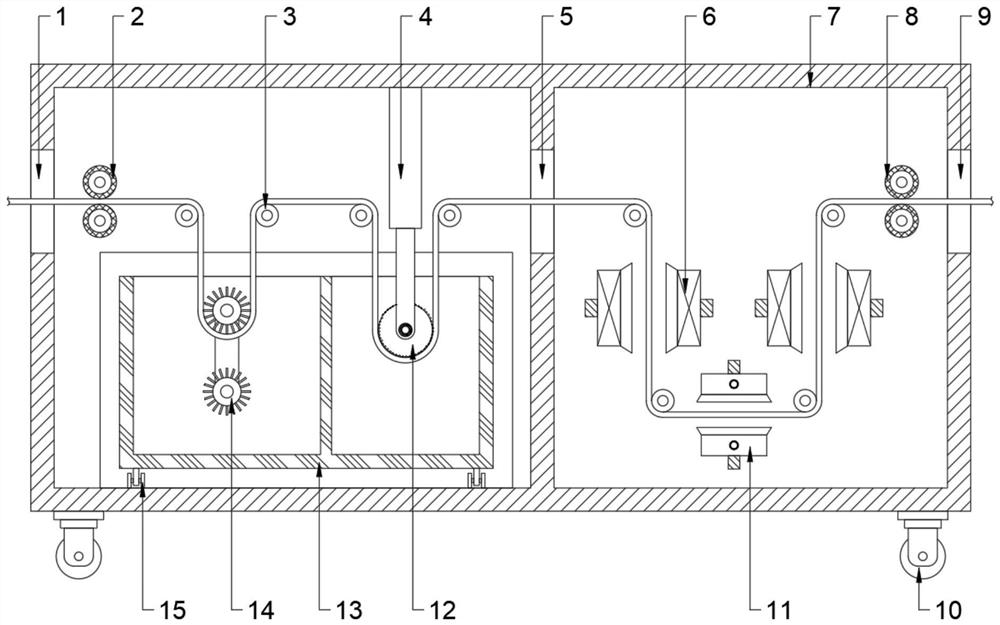

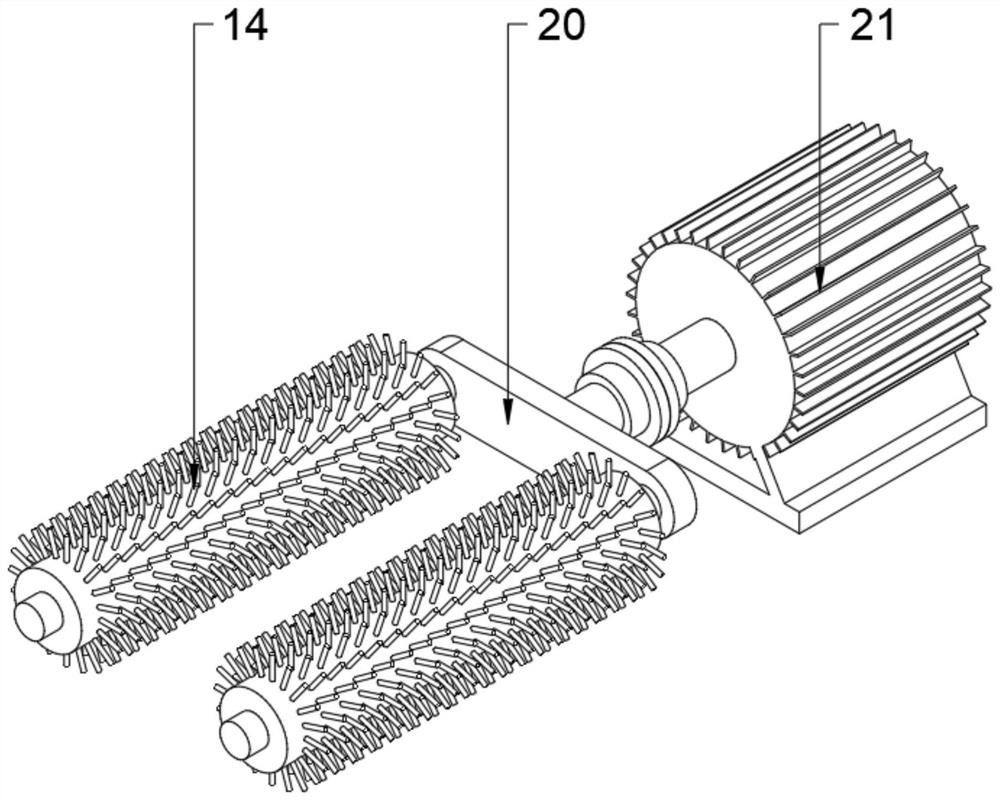

[0025] see Figure 1~4 , in an embodiment of the present invention, a fabric cleaning device for textile processing, including a box body 7 and a cleaning assembly and a drying assembly arranged inside the box body 7, the inside of the box body 7 is divided into a cleaning room and a drying room and The two are communicated through the feeding port 5, and the cleaning assembly is arranged in the clean room, including a cleaning device, a rinsing device and a cleaning cylinder 13. The cleaning cylinder 13 is placed at the bottom of the cleaning room and its interior is divided into a cleaning chamber and a rinsing chamber. cavity, the inside of the cleaning cavity and the rinsing cavity are respectively used to hold cleaning liquid and clear water, which is convenient for cleaning the cloth; And its output shaft passes through the side wall of the cleaning cylinder 13 and is fixedly connected with the transmission bracket 20 rotatably installed inside the cleaning chamber. The ...

Embodiment 2

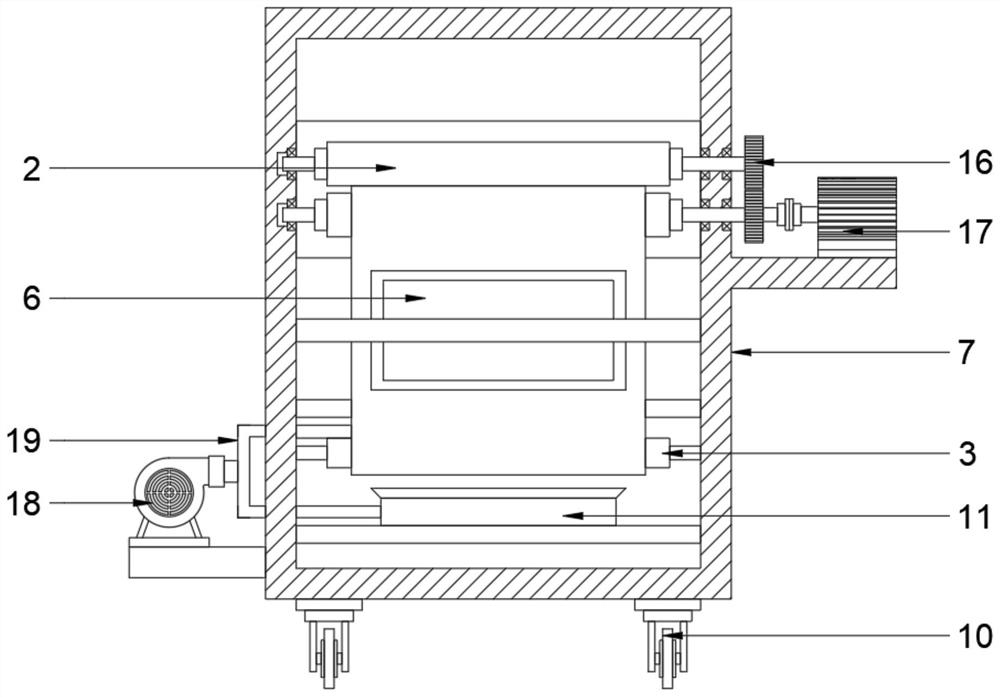

[0034] see Figure 1~2 , in an embodiment of the present invention, a cloth cleaning device for textile processing, in order to ensure the drying quality of the cloth and prevent the cloth from being over-dried, on the basis of Embodiment 1, the drying assembly further includes a blowing device and a blowing device Located between the initial drying device and the re-drying device, the air blowing device includes a blower 18 and an air outlet plate 11, the number of the air outlet plates 11 is two groups and fixedly installed on both sides of the cloth, and the inside of the air outlet plate 11 is provided with The cavity and its side close to the cloth are provided with multiple groups of air outlet holes communicating with the cavity. The blower 18 is fixedly installed on the outer wall of the casing 7 and its air outlet is communicated with an air outlet pipe 19. The air outlet The end of the pipe 19 away from the air blower 18 passes through the side wall of the box body 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com